Broilers and layers serve distinct purposes in poultry farming, with broilers bred specifically for rapid meat production and layers optimized for high egg yield. Broilers grow quickly, reaching market weight in about six weeks, while layers produce a consistent supply of eggs over a longer period. Choosing between broilers and layers depends on whether the focus is on meat or egg production, impacting management practices and resource allocation.

Table of Comparison

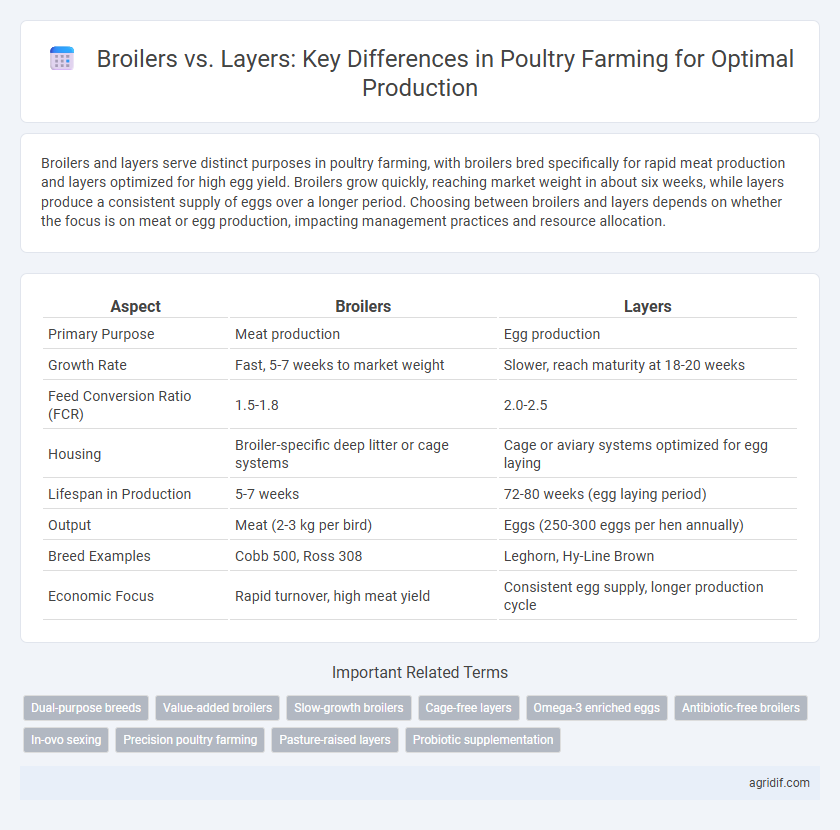

| Aspect | Broilers | Layers |

|---|---|---|

| Primary Purpose | Meat production | Egg production |

| Growth Rate | Fast, 5-7 weeks to market weight | Slower, reach maturity at 18-20 weeks |

| Feed Conversion Ratio (FCR) | 1.5-1.8 | 2.0-2.5 |

| Housing | Broiler-specific deep litter or cage systems | Cage or aviary systems optimized for egg laying |

| Lifespan in Production | 5-7 weeks | 72-80 weeks (egg laying period) |

| Output | Meat (2-3 kg per bird) | Eggs (250-300 eggs per hen annually) |

| Breed Examples | Cobb 500, Ross 308 | Leghorn, Hy-Line Brown |

| Economic Focus | Rapid turnover, high meat yield | Consistent egg supply, longer production cycle |

Understanding Broilers and Layers: Key Differences

Broilers and layers serve distinct roles in poultry production, with broilers bred primarily for rapid growth and meat yield, reaching market weight in as little as 6 to 8 weeks. Layers are specialized for high egg production, typically producing around 250 to 300 eggs annually with a focus on feed efficiency to sustain consistent laying cycles. Understanding these key differences enables poultry farmers to optimize their operations by selecting the appropriate breed based on production goals, whether for meat or egg output.

Genetics and Breeding for Broilers vs Layers

Genetics and breeding in poultry production distinctly target broilers for rapid growth rate, feed efficiency, and muscle yield, emphasizing traits like fast maturity and robust carcass quality. In contrast, layer breeding prioritizes high egg production, shell quality, and prolonged reproductive efficiency, focusing on traits that maximize egg yield over a longer lifespan. Selective breeding programs employ advanced genomic tools to enhance disease resistance and optimize these specialized traits in both broilers and layers for sustainable poultry production.

Growth Rate and Feed Conversion Efficiency

Broilers exhibit a rapid growth rate, reaching market weight in approximately 6 to 8 weeks, which significantly reduces production time compared to layers. Their feed conversion efficiency (FCE) is optimized for muscle development, with an average FCR (feed conversion ratio) of 1.5 to 1.8, meaning they require less feed to gain a kilogram of body weight. Layers, on the other hand, have slower growth rates focused on egg production, with a higher FCR around 2.0 to 2.5, reflecting their nutritional demands for sustained laying performance rather than rapid mass gain.

Housing and Space Requirements

Broilers require spacious, well-ventilated housing with a stocking density of 0.6 to 1 square foot per bird to support rapid growth and reduce heat stress. Layers need specialized housing with nesting boxes and perches, maintaining a lower stocking density of around 1.5 to 2 square feet per bird to optimize egg production and welfare. Proper ventilation, lighting, and temperature control are critical in both systems to promote health and productivity.

Nutritional Needs of Broilers and Layers

Broilers require diets high in protein and energy to support rapid muscle growth, typically containing 20-24% crude protein and energy levels around 3,000 kcal/kg. Layers need balanced nutrition emphasizing calcium and phosphorus to promote eggshell quality, with diets usually containing 16-18% protein and supplemented with 3.5-4% calcium. Proper nutrient formulations tailored to broilers and layers enhance growth performance and egg production efficiency in poultry farming.

Production Cycle and Lifespan Comparison

Broilers have a production cycle of approximately 6 to 8 weeks, optimized for rapid growth and meat yield, while layers begin producing eggs around 18-20 weeks and sustain egg production for 72 to 80 weeks. The lifespan of broilers is short, typically culled after reaching market weight, contrasting with layers, which have a longer productive life but require rest periods and molting. This distinction in production cycle and lifespan influences management practices, cost efficiency, and output priorities in poultry farming.

Economic Returns: Meat vs Egg Production

Broilers generate higher economic returns through rapid meat production with a market-ready weight achieved in 6 to 8 weeks, optimizing feed conversion ratios and reducing production costs. Layers provide consistent income over a longer period by producing eggs daily, with peak productivity typically lasting 12 to 14 months. Market demand and price volatility for chicken meat and eggs influence profitability, making broilers more suitable for quick turnover and layers for steady revenue streams in poultry enterprises.

Health Management and Disease Control

Broilers require rigorous health management protocols to prevent fast-spreading diseases like coccidiosis and avian influenza due to their rapid growth and high-density housing. Layers demand continuous monitoring for bacterial infections such as salmonella and respiratory diseases, with emphasis on vaccination schedules and biosecurity measures to maintain egg production quality. Effective disease control in both broiler and layer operations relies on comprehensive vaccination programs, regular health assessments, and strict sanitation practices to minimize mortality and optimize productivity.

Environmental Impact and Sustainability

Broilers generate higher greenhouse gas emissions due to their rapid growth and intensive feed conversion, whereas layers have a longer lifespan with lower daily emissions but require more prolonged resource use. Waste management is critical in both systems, with broilers producing concentrated manure that can lead to ammonia emissions, while layer farms face challenges in disposing of spent hens and litter. Sustainable poultry production emphasizes optimizing feed efficiency, recycling nutrients from waste, and integrating practices that reduce carbon footprints in both broiler and layer operations.

Choosing the Right Breed for Your Farm Goals

Selecting the appropriate poultry breed aligns directly with farm objectives, with broilers favored for rapid meat production due to their fast growth rate and high feed conversion efficiency, while layers are optimized for consistent egg yield and longevity in laying cycles. Broilers like the Cornish Cross reach market weight in as little as six to eight weeks, making them ideal for meat-focused operations, whereas layer breeds such as Leghorns provide up to 300 eggs annually, supporting egg-centric farms. Evaluating farm infrastructure, market demands, and resource availability ensures a strategic choice between broilers and layers to maximize profitability and sustainability.

Related Important Terms

Dual-purpose breeds

Dual-purpose poultry breeds combine the advantages of broilers and layers by providing moderate meat yield and consistent egg production, making them ideal for small-scale and sustainable farming systems. These breeds, such as the Rhode Island Red and Plymouth Rock, offer economic efficiency by reducing the need for separate flocks and optimizing resource use in poultry production.

Value-added broilers

Value-added broilers in poultry production are selectively bred and nutritionally enhanced to promote faster growth, superior meat quality, and higher feed efficiency compared to traditional layers, which are primarily optimized for egg production. These broilers generate increased economic returns due to their improved carcass yield, enhanced flavor profiles, and reduced production time, making them a preferred choice for meat-focused poultry enterprises.

Slow-growth broilers

Slow-growth broilers in poultry production offer superior meat quality and enhanced animal welfare compared to conventional fast-growing broilers, making them a preferred choice for niche markets focused on sustainability and flavor. While layers are optimized for egg production with high laying rates, slow-growth broilers prioritize muscle development over time, resulting in firmer texture and richer taste in the final poultry product.

Cage-free layers

Broilers are specifically bred for rapid growth and meat production, while cage-free layers prioritize natural behaviors and welfare in egg production without restrictive cages. Cage-free layer systems enhance bird health and egg quality by allowing movement and nesting, which contrasts with intensive broiler production focused on maximizing yield.

Omega-3 enriched eggs

Broilers are primarily raised for meat production, while layers focus on egg production, with Omega-3 enriched eggs specifically produced by selective feeding of layers with omega-3 rich diets such as flaxseed or fish oil. Omega-3 enriched eggs from layers offer enhanced nutritional benefits, including improved cardiovascular health and brain function, making them a valuable product in poultry farming focused on functional foods.

Antibiotic-free broilers

Antibiotic-free broilers are increasingly preferred in poultry production due to consumer demand for healthier, chemical-free meat, emphasizing improved biosecurity and natural growth promoters over traditional antibiotic use. Compared to layers, broilers raised without antibiotics require specialized nutrition and management practices to optimize growth rates while minimizing disease risk in intensive farming systems.

In-ovo sexing

In-ovo sexing technology revolutionizes poultry production by enabling early determination of broiler and layer chick sex, significantly reducing the culling of male layer chicks and improving ethical standards in the industry. This precision technique enhances efficiency and sustainability by optimizing resource allocation tailored to broiler growth or egg production demands.

Precision poultry farming

Precision poultry farming enhances the efficiency of broilers and layers by utilizing real-time data analytics, environmental sensors, and automated feeding systems to optimize growth rates and egg production. Advanced monitoring technologies enable precise control over temperature, humidity, and feeding schedules, significantly improving health outcomes and reducing resource waste in both broiler meat and layer egg production.

Pasture-raised layers

Pasture-raised layers provide higher-quality eggs rich in omega-3 fatty acids and vitamin D compared to conventional broilers raised primarily for meat production. Their outdoor access enhances animal welfare and supports sustainable poultry farming by improving soil health through natural foraging behaviors.

Probiotic supplementation

Probiotic supplementation in broilers enhances growth performance, immune response, and feed conversion efficiency, while in layers, it primarily improves eggshell quality, gut health, and laying rate consistency. Optimizing probiotics tailored to the specific microbial needs of broilers and layers boosts productivity and disease resistance in poultry farming.

Broilers vs Layers for poultry production Infographic

agridif.com

agridif.com