The Deep Pit Manure System stores poultry waste in a large underground pit, allowing for natural decomposition and reduced odor through anaerobic processes, which can be cost-effective but requires regular cleaning and monitoring to prevent overflow. The Belt Manure System continuously removes waste via a conveyor belt, promoting better hygiene and reducing ammonia buildup in the poultry house, yet it involves higher initial investment and maintenance costs. Choosing between these systems depends on farm size, budget, and the desired balance between operational efficiency and environmental impact.

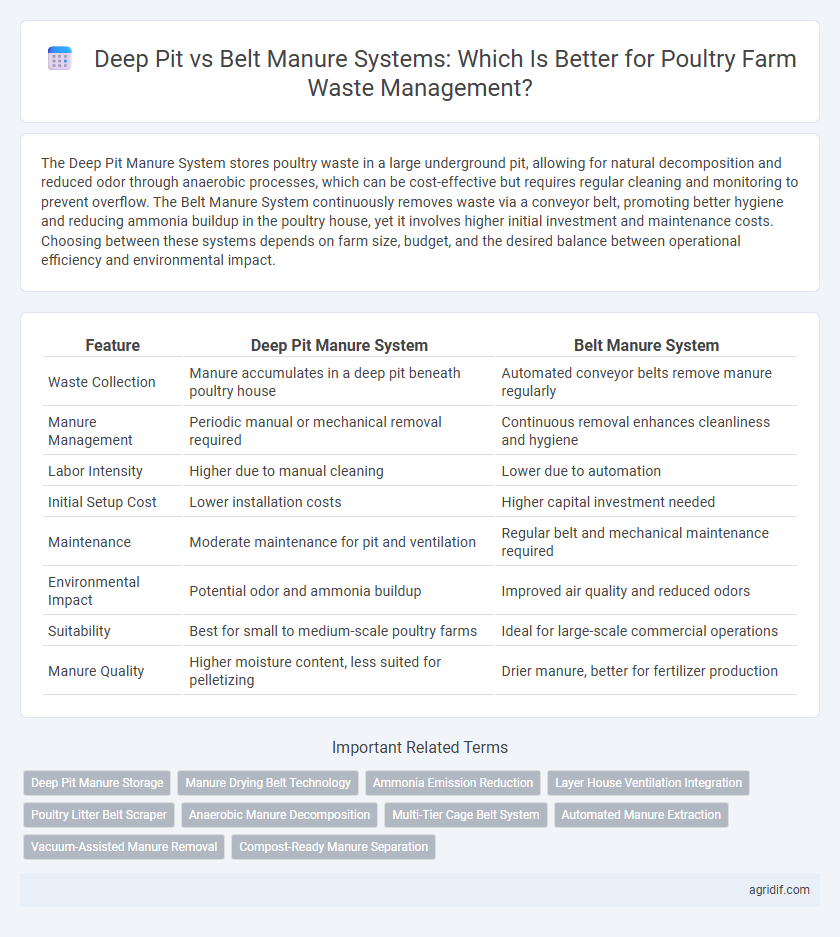

Table of Comparison

| Feature | Deep Pit Manure System | Belt Manure System |

|---|---|---|

| Waste Collection | Manure accumulates in a deep pit beneath poultry house | Automated conveyor belts remove manure regularly |

| Manure Management | Periodic manual or mechanical removal required | Continuous removal enhances cleanliness and hygiene |

| Labor Intensity | Higher due to manual cleaning | Lower due to automation |

| Initial Setup Cost | Lower installation costs | Higher capital investment needed |

| Maintenance | Moderate maintenance for pit and ventilation | Regular belt and mechanical maintenance required |

| Environmental Impact | Potential odor and ammonia buildup | Improved air quality and reduced odors |

| Suitability | Best for small to medium-scale poultry farms | Ideal for large-scale commercial operations |

| Manure Quality | Higher moisture content, less suited for pelletizing | Drier manure, better for fertilizer production |

Introduction to Poultry Waste Management Systems

Deep Pit Manure Systems store poultry waste in large underground pits, allowing natural decomposition to occur over time, which reduces labor but requires regular monitoring to prevent odor and gas buildup. Belt Manure Systems feature automated manure belts that regularly remove waste from the poultry house, minimizing ammonia levels and improving air quality, though they involve higher initial investment and maintenance costs. Both systems aim to enhance hygiene and environmental sustainability in poultry farming by efficiently managing waste and reducing pathogen exposure.

Overview of the Deep Pit Manure System

The Deep Pit Manure System in poultry farming involves collecting waste in a large underground pit beneath the poultry house, allowing manure to accumulate and undergo anaerobic decomposition. This system reduces labor by minimizing frequent manure removal and provides a stable environment that controls odors and moisture levels effectively. Its effectiveness depends on proper design and maintenance to prevent overflow and maintain hygiene in poultry operations.

Features and Functionality of the Belt Manure System

The Belt Manure System in poultry farming features a conveyor belt installed beneath the cages that continuously transports poultry waste away from the birds, enhancing hygiene and reducing ammonia levels. Its automated design facilitates efficient manure removal, minimizes labor costs, and improves overall air quality within the poultry house. This system is particularly effective for large-scale operations, providing consistent waste management and supporting sustainable farming practices.

Efficiency Comparison: Deep Pit vs. Belt Manure Systems

Deep Pit Manure Systems offer high storage capacity with minimal labor but may present challenges in odor control and ammonia emissions, impacting ventilation requirements. Belt Manure Systems enable frequent manure removal, reducing ammonia buildup and improving air quality, which supports healthier poultry conditions and potentially higher productivity. Comparing efficiency, Belt Systems provide better waste management through automated removal and reduced environmental impact, while Deep Pit Systems excel in low-maintenance storage but with less effective waste evacuation.

Impacts on Poultry Health and Biosecurity

The Deep Pit Manure System offers efficient waste storage by containing manure beneath the poultry house, reducing ammonia emissions and minimizing pathogen exposure which supports better respiratory health in birds. The Belt Manure System removes waste frequently, lowering moisture and ammonia levels on the poultry house floor, enhancing litter quality and reducing the risk of bacterial growth that can cause diseases. Both systems improve biosecurity by controlling pathogen spread, but the Belt System's frequent removal provides superior control over microbial contamination compared to the static storage of the Deep Pit System.

Environmental Considerations and Emissions

The Deep Pit Manure System accumulates waste beneath poultry houses, producing higher ammonia and methane emissions due to anaerobic decomposition, which negatively impact air quality and contribute to greenhouse gases. In contrast, the Belt Manure System facilitates frequent waste removal, reducing odor and ammonia emissions by maintaining aerobic conditions, thereby improving environmental outcomes. Choosing the Belt System aids in controlling nitrogen runoff and minimizing the ecological footprint associated with poultry waste management.

Labor and Maintenance Requirements

Deep Pit Manure Systems require less frequent waste removal but involve intensive manual labor during cleanout periods, demanding substantial effort and time for scraping and disposal. Belt Manure Systems automate waste removal through conveyors, significantly reducing daily labor requirements and simplifying maintenance tasks. Maintenance for Deep Pit Systems includes periodic pit emptying and ventilation management, while Belt Systems require regular inspection and upkeep of mechanical components to ensure continuous operation.

Cost Analysis: Installation and Operational Expenses

The Deep Pit Manure System requires lower initial installation costs due to its simpler design and minimal mechanical components, resulting in reduced capital expenditure for poultry farms. Operational expenses remain relatively low as manual or periodic removal limits maintenance, though labor can increase long-term costs. In contrast, the Belt Manure System demands higher upfront investment in automated equipment and infrastructure, but offers decreased operational costs through continuous waste removal, reduced labor, and improved manure handling efficiency.

Suitability for Different Poultry Farm Scales

The Deep Pit Manure System is highly suitable for large-scale poultry farms due to its capacity to store significant volumes of waste with minimal labor, enhancing efficiency in extensive operations. In contrast, the Belt Manure System is ideal for small to medium-sized farms, offering automated waste removal that reduces moisture content and improves hygiene in confined environments. Selecting the appropriate system depends on farm size, with deep pits favored for high-density flocks and belt systems optimizing cleanliness and waste handling in more moderate production levels.

Conclusion: Choosing the Right Manure Management System

Selecting the ideal manure management system in poultry farming hinges on factors such as farm size, budget, environmental regulations, and labor availability. The Deep Pit Manure System offers cost-effective solid waste accumulation but requires regular cleaning to prevent odor and pathogen buildup. In contrast, the Belt Manure System provides continuous waste removal, improving hygiene and air quality, which is especially beneficial for larger operations seeking automation and reduced labor costs.

Related Important Terms

Deep Pit Manure Storage

Deep Pit Manure Storage in poultry farming offers a cost-effective solution by accumulating waste beneath the poultry house floor, reducing labor and minimizing odor through anaerobic decomposition. This system contrasts with the Belt Manure System, which actively removes manure regularly, making Deep Pit Storage more suitable for large-scale operations where long-term waste containment is prioritized.

Manure Drying Belt Technology

Manure drying belt technology in belt manure systems enables efficient moisture removal, reducing ammonia emissions and improving pathogen control compared to traditional deep pit manure systems. This advanced waste management approach enhances nutrient recovery, minimizes odor, and supports sustainable poultry farming practices by producing easily handled, dry manure suitable for transportation and use as fertilizer.

Ammonia Emission Reduction

The Belt Manure System significantly reduces ammonia emissions compared to the Deep Pit Manure System by promptly removing waste from poultry houses, limiting manure exposure to air and microbial activity that generates ammonia. Research shows ammonia levels can be lowered by up to 50% with belt systems, improving air quality and bird health in poultry farming operations.

Layer House Ventilation Integration

The Deep Pit Manure System offers superior ammonia control due to its ability to contain waste beneath the floor, directly reducing airborne pollutants that affect layer house ventilation efficiency. In contrast, the Belt Manure System facilitates frequent waste removal, improving air quality by minimizing moisture and harmful gases, thus enhancing ventilation performance and bird health in layer houses.

Poultry Litter Belt Scraper

The Poultry Litter Belt Scraper in the Belt Manure System offers efficient and continuous waste removal by transporting litter away from poultry houses, reducing ammonia levels and improving air quality compared to the Deep Pit Manure System, which relies on periodic emptying leading to odor buildup. Enhanced by automated cleaning cycles, the Belt Scraper system optimizes manure management, supporting better flock health and streamlined farm operations.

Anaerobic Manure Decomposition

The Deep Pit Manure System promotes anaerobic manure decomposition by creating oxygen-limited environments that accelerate the breakdown of organic waste into biogas and nutrient-rich byproducts, enhancing nutrient recycling in poultry farms. In contrast, the Belt Manure System primarily relies on mechanical manure removal and aerobic decomposition processes, which reduce odor and pathogen load but generate less biogas compared to anaerobic conditions in deep pits.

Multi-Tier Cage Belt System

The Multi-Tier Cage Belt System in poultry farming offers superior waste management by efficiently collecting manure on conveyor belts, reducing ammonia emissions and improving bird health compared to the Deep Pit Manure System, which often accumulates waste and increases odor issues. Enhanced waste removal frequency in the belt system optimizes litter quality and environmental conditions, promoting sustainable production in multi-tier cage operations.

Automated Manure Extraction

The Deep Pit Manure System offers efficient waste accumulation with minimal maintenance but requires periodic manual intervention for manure removal, while the Belt Manure System incorporates automated manure extraction, continuously transporting waste out of the poultry house to reduce labor and improve hygiene. Automated manure extraction in Belt Systems enhances environmental control by minimizing ammonia buildup and facilitates easier manure handling for sustainable poultry farming operations.

Vacuum-Assisted Manure Removal

Vacuum-assisted manure removal in poultry farming enhances waste management by efficiently extracting litter and manure, reducing ammonia emissions and labor costs. Deep pit manure systems utilize gravity-driven removal with vacuum assistance, providing superior odor control and minimizing environmental contamination compared to belt manure systems that rely on mechanical collection and periodic removal.

Compost-Ready Manure Separation

Deep pit manure systems allow for prolonged accumulation and partial anaerobic decomposition of poultry waste, resulting in nutrient-rich, semi-solid manure that requires drying before composting; in contrast, belt manure systems continuously remove fresh droppings, enabling faster separation of compost-ready manure with reduced moisture content and odor levels, thereby enhancing overall waste management efficiency and compost quality in poultry farming.

Deep Pit Manure System vs Belt Manure System for Waste Management Infographic

agridif.com

agridif.com