Manual egg collection in poultry farming requires significant labor input, limiting efficiency and increasing operational costs. Automated egg collection systems reduce manual handling, speed up the process, and minimize the risk of egg damage, enhancing overall productivity. Investing in automation improves labor efficiency by allowing workers to focus on other essential farm management tasks.

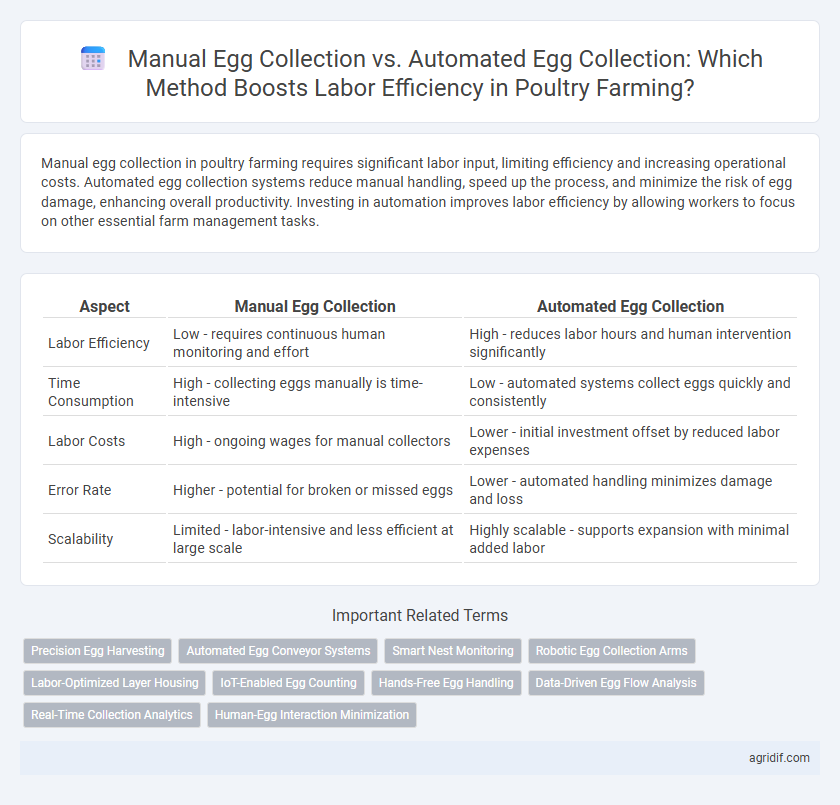

Table of Comparison

| Aspect | Manual Egg Collection | Automated Egg Collection |

|---|---|---|

| Labor Efficiency | Low - requires continuous human monitoring and effort | High - reduces labor hours and human intervention significantly |

| Time Consumption | High - collecting eggs manually is time-intensive | Low - automated systems collect eggs quickly and consistently |

| Labor Costs | High - ongoing wages for manual collectors | Lower - initial investment offset by reduced labor expenses |

| Error Rate | Higher - potential for broken or missed eggs | Lower - automated handling minimizes damage and loss |

| Scalability | Limited - labor-intensive and less efficient at large scale | Highly scalable - supports expansion with minimal added labor |

Introduction to Egg Collection Methods in Poultry Farming

Manual egg collection in poultry farming involves labor-intensive processes where workers gather eggs by hand, resulting in higher labor costs and potential inconsistencies in egg handling. Automated egg collection systems utilize conveyor belts and mechanized equipment, significantly increasing labor efficiency by reducing the need for manual intervention and minimizing egg breakage. Adoption of automated collection improves overall productivity and streamlines operations in large-scale poultry farms.

Overview of Manual Egg Collection

Manual egg collection in poultry farming involves workers gathering eggs by hand from nesting boxes or floors, requiring significant labor input and time. This method allows careful inspection of eggs for quality and damage but can be inefficient for large-scale operations due to high labor costs and slower collection rates. Despite its limitations, manual collection remains common in small or traditional farms where automation investment is impractical.

Overview of Automated Egg Collection Systems

Automated egg collection systems use conveyor belts and robotic arms to transport eggs from nesting areas to storage units, significantly reducing manual labor requirements. These systems improve labor efficiency by minimizing the time workers spend on egg handling and decreasing breakage rates through gentle handling mechanisms. Integration with monitoring technologies allows real-time tracking of egg production, enhancing overall operational efficiency in poultry farming.

Labor Requirements in Manual vs Automated Collection

Manual egg collection in poultry farming demands significant labor input, requiring workers to gather eggs frequently to prevent breakage and contamination. Automated egg collection systems drastically reduce labor requirements by utilizing conveyor belts and sensors to transport eggs efficiently, minimizing the need for manual handling. This shift enhances labor efficiency, allowing poultry operations to reallocate human resources to other critical tasks such as flock management and health monitoring.

Time Efficiency Comparison

Manual egg collection requires significant labor hours, averaging 2 to 3 minutes per nesting box, resulting in slower overall productivity especially in large-scale poultry operations. Automated egg collection systems reduce collection time by up to 70%, streamlining the process through conveyor belts and mechanized collection trays, which accelerates workflow and minimizes human intervention. Time efficiency gains from automation lead to increased labor productivity, enabling poultry farms to reallocate workforce focus toward maintenance and animal welfare tasks.

Impact on Egg Quality and Breakage Rates

Manual egg collection in poultry farming often results in higher breakage rates due to inconsistent handling and slower collection intervals, negatively impacting egg quality. Automated egg collection systems reduce labor costs and minimize physical contact, preserving shell integrity and maintaining superior egg quality through consistent, gentle handling. Implementation of automated systems improves overall labor efficiency while significantly decreasing egg breakage incidents, enhancing profitability and product reliability.

Cost Implications: Initial Investment and Maintenance

Manual egg collection requires minimal initial investment but incurs higher ongoing labor costs due to intensive manual handling and slower processing times. Automated egg collection systems demand substantial upfront capital for equipment installation and integration but significantly reduce labor expenses through faster, consistent egg handling and decreased risk of damage. Maintenance costs for automated systems include periodic servicing and repairs, which are generally offset by labor savings and improved operational efficiency in large-scale poultry farms.

Worker Safety and Ergonomics Considerations

Manual egg collection in poultry farming often leads to repetitive strain injuries and increased fatigue due to constant bending and lifting, negatively impacting worker safety and ergonomics. Automated egg collection systems significantly reduce physical labor by using conveyor belts and robotic arms, minimizing human exposure to hazardous environments and repetitive tasks. Implementing automated solutions enhances labor efficiency while promoting healthier working conditions and reducing workplace accidents.

Scalability for Small and Large Poultry Farms

Manual egg collection offers flexibility and low initial costs, making it ideal for small-scale poultry farms with limited labor resources; however, it can become labor-intensive and less efficient as flock size increases. Automated egg collection systems significantly enhance labor efficiency by reducing manual handling and minimizing egg breakage, providing scalable solutions suited for both medium and large poultry operations. Investing in automated technology supports sustainable growth by streamlining workflow and optimizing labor allocation in expansive poultry farming enterprises.

Future Trends and Innovations in Egg Collection

Automated egg collection systems significantly enhance labor efficiency by reducing manual handling and minimizing breakage in poultry farms. Future trends emphasize integrating AI-driven robotics and IoT sensors to optimize collection timing and monitor egg quality in real-time. Innovations like smart conveyor belts and automated sorting mechanisms are set to transform egg collection, boosting productivity while lowering labor costs.

Related Important Terms

Precision Egg Harvesting

Manual egg collection relies on human labor, which can lead to inconsistent timing and risk of egg damage, whereas automated egg collection systems utilize sensors and conveyor belts to ensure precision egg harvesting with minimal breakage and optimized labor efficiency. Automated systems reduce labor costs and improve operational productivity by enabling continuous, accurate egg gathering aligned with optimal harvest cycles.

Automated Egg Conveyor Systems

Automated egg conveyor systems significantly enhance labor efficiency in poultry farming by reducing manual handling time and minimizing the risk of egg damage during collection. These systems streamline the collection process, allowing continuous, real-time transport of eggs from nesting boxes to packing areas, increasing overall productivity and reducing labor costs.

Smart Nest Monitoring

Smart nest monitoring systems enhance labor efficiency by reducing manual egg collection efforts and enabling real-time tracking of egg laying patterns. Automated egg collection integrated with smart sensors minimizes human error and streamlines operations, leading to increased productivity and optimized workforce allocation in poultry farms.

Robotic Egg Collection Arms

Robotic egg collection arms significantly enhance labor efficiency in poultry farming by automating the retrieval and handling of eggs, reducing manual labor costs and minimizing egg breakage. These advanced systems integrate precise sensors and AI technology to streamline egg collection, ensuring consistent quality and boosting overall productivity.

Labor-Optimized Layer Housing

Manual egg collection in labor-optimized layer housing demands significant human labor, increasing operational costs and limiting scalability, while automated egg collection systems enhance labor efficiency by minimizing manual handling and allowing consistent, faster egg retrieval. Implementing automated systems reduces workforce needs and improves egg hygiene, directly boosting productivity and profitability in poultry farming.

IoT-Enabled Egg Counting

Manual egg collection relies heavily on labor-intensive processes, increasing time and labor costs, while IoT-enabled egg counting systems automate monitoring and provide real-time data, significantly enhancing labor efficiency and reducing human error. Integrating smart sensors and automated collection platforms streamlines operations, allowing poultry farmers to optimize workforce allocation and improve overall productivity.

Hands-Free Egg Handling

Automated egg collection systems significantly enhance labor efficiency in poultry farming by enabling hands-free egg handling, reducing manual labor and minimizing the risk of egg damage. Compared to manual egg collection, automated methods streamline the process, improve worker safety, and increase overall productivity by continuously transporting eggs from the coop to packing areas without human intervention.

Data-Driven Egg Flow Analysis

Data-driven egg flow analysis reveals that automated egg collection systems increase labor efficiency by reducing manual handling time by up to 70%, streamlining the collection process, and minimizing egg damage rates compared to manual methods. Real-time monitoring and precise tracking of egg production patterns enable optimized workforce allocation and faster response to bottlenecks in the poultry farm operation.

Real-Time Collection Analytics

Manual egg collection relies heavily on human labor, resulting in slower data processing and limited real-time insights, which can lead to inefficiencies in labor management. Automated egg collection systems integrate real-time collection analytics, enabling precise labor allocation and immediate detection of collection inconsistencies, significantly enhancing overall operational efficiency on poultry farms.

Human-Egg Interaction Minimization

Automated egg collection systems significantly reduce human-egg interaction by using conveyor belts and sensors to transport eggs directly from nests to packing areas, minimizing labor requirements and contamination risks. Manual egg collection demands continuous human handling, increasing labor intensity and the potential for egg damage and biosecurity breaches, thereby decreasing overall efficiency in poultry farming operations.

Manual Egg Collection vs Automated Egg Collection for Labor Efficiency Infographic

agridif.com

agridif.com