Manual collection of eggs in poultry farming allows for careful inspection of each egg, reducing the risk of damage and ensuring quality control. Automated collection systems increase efficiency by rapidly gathering eggs, minimizing labor costs and reducing the chance of contamination. Choosing between manual and automated collection depends on the scale of the operation, budget, and desired levels of precision and automation.

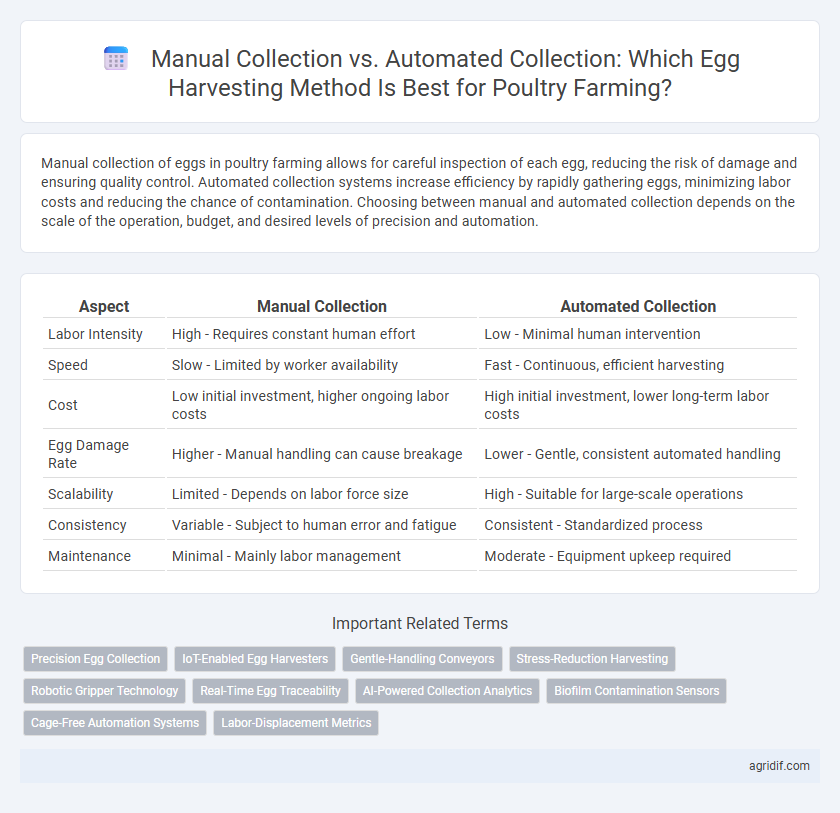

Table of Comparison

| Aspect | Manual Collection | Automated Collection |

|---|---|---|

| Labor Intensity | High - Requires constant human effort | Low - Minimal human intervention |

| Speed | Slow - Limited by worker availability | Fast - Continuous, efficient harvesting |

| Cost | Low initial investment, higher ongoing labor costs | High initial investment, lower long-term labor costs |

| Egg Damage Rate | Higher - Manual handling can cause breakage | Lower - Gentle, consistent automated handling |

| Scalability | Limited - Depends on labor force size | High - Suitable for large-scale operations |

| Consistency | Variable - Subject to human error and fatigue | Consistent - Standardized process |

| Maintenance | Minimal - Mainly labor management | Moderate - Equipment upkeep required |

Introduction to Egg Harvesting Methods in Poultry Farming

Egg harvesting in poultry farming involves two primary methods: manual collection and automated collection. Manual collection requires workers to gather eggs by hand from nesting boxes, providing flexibility but increasing labor costs and time. Automated collection systems use conveyor belts and sensors to efficiently transport eggs from nests to collection points, improving speed, hygiene, and reducing breakage while requiring significant upfront investment.

Manual Egg Collection: Traditional Practices and Processes

Manual egg collection involves workers carefully gathering eggs by hand from nests, ensuring minimal damage and maintaining egg quality. This traditional method allows for immediate inspection of eggs for cracks or defects, reducing contamination risks and preserving freshness. Despite being labor-intensive, manual collection supports small-scale farms by offering flexibility and personalized care for each laying hen.

Automated Egg Collection: Modern Technology Overview

Automated egg collection systems in poultry farming utilize conveyor belts, sensors, and robotics to ensure efficient, hygienic, and timely harvesting of eggs, significantly reducing labor costs and minimizing egg damage. Modern technologies such as IoT integration and real-time monitoring enhance productivity by providing data analytics on egg production rates and system performance. These advancements promote sustainable farm management and improve overall operational efficiency compared to traditional manual collection methods.

Efficiency Comparison: Manual vs Automated Egg Harvesting

Automated egg harvesting systems significantly increase efficiency by reducing labor time and minimizing egg damage compared to manual collection, which is labor-intensive and prone to human error. Equipment such as conveyor belts and mechanical collectors streamline the collection process, enabling faster throughput and consistent egg quality. Studies show automated methods can boost productivity by over 50% while lowering operational costs in large-scale poultry farms.

Labor Requirements in Manual and Automated Egg Collection

Manual egg collection demands significant labor, requiring farmworkers to gather eggs multiple times daily, increasing labor costs and time investment. Automated egg collection systems reduce labor requirements by utilizing conveyor belts and robotic mechanisms, allowing continuous and efficient egg harvesting with minimal human intervention. This automation enhances productivity and lowers operational expenses by streamlining the egg collection process.

Impact on Egg Quality and Breakage Rates

Manual collection in poultry farming often results in lower breakage rates due to careful handling, preserving egg quality through minimal physical stress. Automated collection systems enhance efficiency and consistency but may increase the risk of egg damage if not properly calibrated or maintained. Optimizing automated mechanisms with soft-touch conveyors and shock absorption technology significantly reduces breakage, maintaining high-quality egg standards.

Cost Analysis: Initial Investment and Operational Expenses

Manual collection in poultry farming requires lower initial investment but incurs higher operational expenses due to increased labor costs and time consumption. Automated collection systems involve substantial upfront capital for equipment purchase and installation, yet reduce ongoing labor expenses and enhance efficiency. Over time, automated methods often lead to lower total cost per egg harvested, making them more economically viable for large-scale operations.

Biosecurity and Hygiene Considerations for Both Methods

Manual egg collection in poultry farming allows for close inspection of each egg, reducing the risk of contamination and enabling immediate removal of soiled or cracked eggs, which supports high biosecurity standards. Automated collection systems minimize human contact, lowering the chances of pathogen transmission but require thorough and regular sanitation protocols to prevent bacterial buildup on conveyors and collection belts. Both methods demand strict hygiene management, with manual collection relying on worker training and automated systems necessitating advanced cleaning technology to maintain egg quality and flock health.

Scalability and Suitability for Different Farm Sizes

Manual egg collection suits small-scale poultry farms due to lower initial costs and simpler labor requirements, ensuring careful handling but facing scalability limitations as flock size grows. Automated collection systems offer high scalability for large and commercial operations by streamlining the harvesting process, reducing labor costs, and minimizing egg damage through consistent mechanical handling. Farm size, budget constraints, and labor availability are key factors in deciding between manual versus automated egg collection methods for optimal productivity.

Future Trends in Egg Collection Systems in Poultry Farming

Future trends in egg collection systems in poultry farming emphasize increased automation and integration of smart technologies to enhance efficiency and reduce labor costs. Automated collection systems equipped with sensors and IoT devices enable real-time monitoring of egg quality, temperature, and harvesting schedules, optimizing both productivity and animal welfare. Advances in robotics and AI-driven sorting mechanisms are set to revolutionize egg handling by minimizing human error and improving traceability throughout the supply chain.

Related Important Terms

Precision Egg Collection

Manual collection relies on human labor for egg harvesting, which can result in inconsistent timing and increased risk of egg damage, reducing overall precision. Automated collection systems utilize sensors and conveyor mechanisms to ensure consistent, timely egg retrieval, significantly enhancing precision and minimizing breakage in poultry farming operations.

IoT-Enabled Egg Harvesters

IoT-enabled egg harvesters revolutionize poultry farming by integrating sensors and data analytics to optimize egg collection efficiency and reduce labor costs compared to manual methods. These smart systems monitor egg quality and automate sorting while providing real-time insights for improved farm management and increased productivity.

Gentle-Handling Conveyors

Gentle-handling conveyors in automated egg harvesting minimize breakage and maintain egg quality by reducing physical contact compared to manual collection methods. This technology enhances efficiency and hygiene in poultry farming operations, leading to higher productivity and lower labor costs.

Stress-Reduction Harvesting

Manual collection in poultry farming allows gentle handling of eggs, reducing stress on hens by minimizing sudden disturbances and ensuring careful selection, while automated collection systems use conveyor belts and sensors to swiftly gather eggs, significantly decreasing human interaction and promoting a calm environment for stress-reduction harvesting. Research indicates that automated egg collection reduces hen anxiety levels and improves overall welfare by maintaining consistent routines and limiting the need for frequent human presence.

Robotic Gripper Technology

Robotic gripper technology in automated egg harvesting enhances efficiency by minimizing egg breakage and reducing labor costs through precise handling and consistent speed. Manual collection relies heavily on human dexterity, making it prone to errors and slower throughput compared to the scalability offered by robotic systems equipped with adaptive sensors and soft gripping mechanisms.

Real-Time Egg Traceability

Automated egg collection systems enable real-time egg traceability by integrating RFID technology and data analytics, ensuring precise tracking of egg origin, quality, and handling throughout the supply chain. Manual collection lacks this continuous data capture, resulting in limited traceability and increased risk of errors or contamination in egg harvesting operations.

AI-Powered Collection Analytics

AI-powered collection analytics in automated egg harvesting optimize yield by accurately tracking laying patterns and identifying anomalies, reducing egg damage and labor costs compared to manual collection. Real-time data integration enhances decision-making, improving flock management and overall productivity in poultry farming operations.

Biofilm Contamination Sensors

Biofilm contamination sensors integrated into automated egg harvesting systems detect microbial biofilms on collection surfaces, reducing contamination risk and improving egg hygiene compared to manual collection methods. These sensors enable timely cleaning interventions by continuously monitoring biofilm development, ensuring higher biosecurity standards in poultry farming operations.

Cage-Free Automation Systems

Cage-free automation systems for egg harvesting increase efficiency by reducing labor costs and minimizing egg breakage compared to manual collection. These systems utilize sensors and conveyors to gently collect eggs from nest boxes, ensuring higher hygiene standards and improved animal welfare in poultry farming.

Labor-Displacement Metrics

Manual collection in poultry farming requires 50-70% more labor hours compared to automated systems, leading to higher operational costs and increased worker fatigue. Automated egg harvesting reduces labor displacement by up to 60%, enhancing efficiency while maintaining consistent egg quality and minimizing human error.

Manual Collection vs Automated Collection for Egg Harvesting Infographic

agridif.com

agridif.com