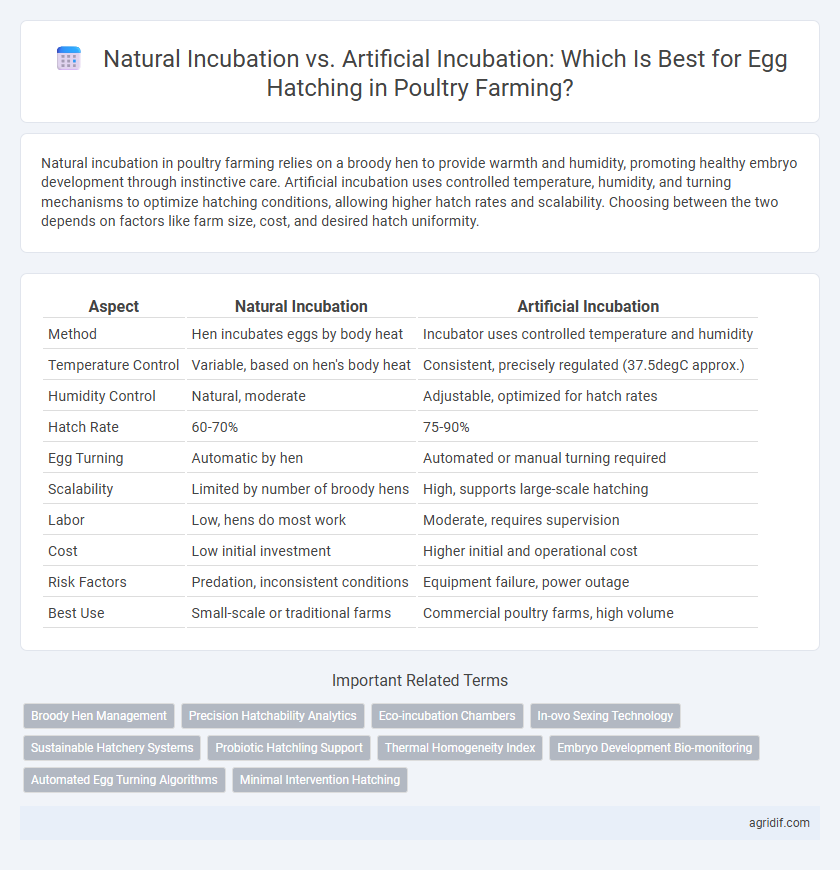

Natural incubation in poultry farming relies on a broody hen to provide warmth and humidity, promoting healthy embryo development through instinctive care. Artificial incubation uses controlled temperature, humidity, and turning mechanisms to optimize hatching conditions, allowing higher hatch rates and scalability. Choosing between the two depends on factors like farm size, cost, and desired hatch uniformity.

Table of Comparison

| Aspect | Natural Incubation | Artificial Incubation |

|---|---|---|

| Method | Hen incubates eggs by body heat | Incubator uses controlled temperature and humidity |

| Temperature Control | Variable, based on hen's body heat | Consistent, precisely regulated (37.5degC approx.) |

| Humidity Control | Natural, moderate | Adjustable, optimized for hatch rates |

| Hatch Rate | 60-70% | 75-90% |

| Egg Turning | Automatic by hen | Automated or manual turning required |

| Scalability | Limited by number of broody hens | High, supports large-scale hatching |

| Labor | Low, hens do most work | Moderate, requires supervision |

| Cost | Low initial investment | Higher initial and operational cost |

| Risk Factors | Predation, inconsistent conditions | Equipment failure, power outage |

| Best Use | Small-scale or traditional farms | Commercial poultry farms, high volume |

Introduction to Egg Incubation Methods in Poultry Farming

Natural incubation in poultry farming involves the hen sitting on eggs to provide warmth and humidity essential for embryo development, relying on instinctive behavior and environmental conditions. Artificial incubation uses controlled incubators to maintain optimal temperature, humidity, and ventilation, enabling higher hatch rates and efficient large-scale production. Understanding these incubation methods helps farmers select appropriate techniques based on resources, flock size, and hatchability goals.

Defining Natural vs Artificial Incubation

Natural incubation involves a broody hen sitting on eggs to provide consistent warmth and humidity required for embryo development, mimicking natural environmental conditions. Artificial incubation utilizes controlled temperature, humidity, and ventilation within incubators to optimize hatching rates and reduce dependency on broody hens. Both methods affect hatchability, chick quality, and operational scale in poultry farming.

Key Advantages of Natural Incubation

Natural incubation offers key advantages such as enhanced chick immunity due to gradual temperature fluctuations and natural maternal behaviors that improve hatchability rates. The presence of the hen provides consistent humidity and warmth, reducing egg mortality and promoting healthier chick development. This method also decreases energy costs and equipment reliance, making it more sustainable and cost-effective for small-scale poultry farmers.

Key Benefits of Artificial Incubation

Artificial incubation offers precise control over temperature, humidity, and ventilation, significantly increasing hatch rates and reducing embryo mortality. It enables consistent, year-round hatching independent of seasonal variations, improving productivity and operational scheduling. The scalability of artificial incubation supports large-scale poultry farming, enhancing uniformity in chick quality and health through monitored, optimized conditions.

Comparative Success Rates: Natural vs Artificial Incubation

Natural incubation relies on a hen's consistent body heat and turning behavior, resulting in hatching success rates typically between 70% and 85%. Artificial incubation, through controlled temperature, humidity, and automated egg turning, enhances precision and often achieves success rates of 85% to 95%. Factors such as environmental control, automation technology, and breed-specific conditions significantly influence the comparative success rates of natural versus artificial incubation.

Labor and Resource Requirements in Incubation Methods

Natural incubation requires less technological investment but demands extensive labor for consistent egg turning and temperature regulation by the broody hen. Artificial incubation involves higher initial costs for incubators and energy consumption yet significantly reduces manual labor through automated temperature and humidity controls. Resource allocation in artificial incubation allows for greater scalability and uniform hatch rates compared to the variable outcomes in natural incubation.

Impact on Chick Health and Survival

Natural incubation provides optimal temperature and humidity by hens, enhancing chick health through gradual microbial exposure and stronger immune systems. Artificial incubation allows precise environmental control and higher hatch rates but may expose chicks to more pathogens, sometimes leading to weaker immune responses. Studies indicate that natural incubation often results in better chick survival rates due to improved initial immunity and reduced stress during hatching.

Economic Considerations for Poultry Farmers

Natural incubation requires minimal investment in equipment and energy, reducing initial costs for small-scale poultry farmers. Artificial incubation increases hatch rates and allows for precise temperature and humidity control, improving productivity and enabling larger-scale operations with faster turnover. However, the higher upfront cost and ongoing energy expenses must be balanced against the potential for increased chick quality and uniformity in commercial settings.

Environmental Factors Influencing Incubation Choice

Environmental factors such as temperature stability, humidity levels, and ventilation critically impact the choice between natural and artificial incubation in poultry farming. Natural incubation depends on the hen's ability to maintain consistent warmth and moisture, making it susceptible to fluctuations caused by weather changes and predator disturbances. Artificial incubation systems offer controlled environments that optimize hatch rates by regulating temperature, humidity, and airflow, ensuring uniform development regardless of external climatic conditions.

Best Practices and Recommendations for Egg Hatching

Natural incubation, relying on the broody hen's warmth and humidity, ensures optimal temperature control and promotes stronger chick development due to natural movement and ventilation. Artificial incubation, using controlled incubators, offers precise regulation of temperature, humidity, and turning frequency, increasing hatch rates and allowing large-scale hatching. Best practices include maintaining consistent temperature around 99.5degF (37.5degC), humidity levels between 50-60% during incubation with a rise to 65-75% during hatching, and regular egg turning every 4-6 hours to maximize embryo viability and survival rates.

Related Important Terms

Broody Hen Management

Broody hen management plays a crucial role in natural incubation by ensuring optimal warmth and humidity for egg development, promoting strong chick vitality and reduced mortality rates. Artificial incubation, while allowing precise temperature and humidity control through incubators, demands rigorous monitoring to mimic natural conditions and support consistent hatch rates in poultry farming.

Precision Hatchability Analytics

Natural incubation relies on the hen's consistent body temperature and humidity control, offering limited monitoring capabilities, while artificial incubation uses advanced sensors and automation to maintain optimal conditions, enhancing precision hatchability analytics. Data-driven artificial incubation systems enable real-time adjustments and detailed tracking of embryo development, significantly improving hatch rates and reducing variability compared to natural methods.

Eco-incubation Chambers

Eco-incubation chambers provide a sustainable alternative to traditional natural incubation by regulating temperature, humidity, and airflow to optimize egg hatching rates while minimizing environmental impact. These energy-efficient systems reduce reliance on fossil fuels and promote consistent embryo development, enhancing the sustainability and productivity of poultry farming operations.

In-ovo Sexing Technology

In-ovo sexing technology revolutionizes poultry farming by enabling early identification of chick sex during artificial incubation, reducing the ethical concerns and resource waste associated with hatching unwanted males. Natural incubation relies on hen behavior but lacks the precision and efficiency of artificial incubation paired with in-ovo sexing, which enhances hatchery productivity and aligns with sustainable poultry management practices.

Sustainable Hatchery Systems

Natural incubation relies on hen broodiness to maintain optimal temperature and humidity for embryo development, promoting biodiversity and reducing energy consumption. Artificial incubation systems offer precise environmental control and higher hatch rates but require sustainable energy sources and efficient design to minimize ecological impact.

Probiotic Hatchling Support

Natural incubation promotes the development of beneficial gut microbiota in hatchlings through direct contact with the hen, enhancing their immune system naturally. Artificial incubation requires the strategic use of probiotic supplements to ensure hatchlings acquire essential microorganisms for optimal growth and disease resistance.

Thermal Homogeneity Index

The Thermal Homogeneity Index in natural incubation varies due to hen movement and ambient temperature fluctuations, often resulting in uneven embryo development. Artificial incubation systems maintain a higher and more consistent Thermal Homogeneity Index by precisely controlling temperature and humidity, optimizing hatch rates and chick quality.

Embryo Development Bio-monitoring

Natural incubation relies on the hen's consistent body temperature and humidity to regulate embryo development, providing real-time biological feedback through her behavior and brooding patterns. Artificial incubation employs precise temperature, humidity, and gas concentration controls combined with advanced bio-monitoring sensors to optimize embryo growth conditions and improve hatch rates.

Automated Egg Turning Algorithms

Automated egg turning algorithms in artificial incubation optimize temperature, humidity, and rotation intervals to mimic natural incubation conditions, enhancing hatch rates and chick viability. These advanced systems reduce manual labor and ensure consistent egg rotation, preventing embryo adhesion and promoting uniform development compared to natural incubation methods.

Minimal Intervention Hatching

Natural incubation relies on the broody hen's instinctive warmth and humidity regulation, promoting optimal embryo development with minimal human intervention and fostering stronger chick viability. Artificial incubation offers controlled temperature and humidity settings, enabling large-scale hatching efficiency but requires precise monitoring to mimic natural conditions and reduce stress on embryos.

Natural Incubation vs Artificial Incubation for Egg Hatching Infographic

agridif.com

agridif.com