Wet litter in poultry farming creates an unhealthy environment that promotes bacterial growth and ammonia buildup, leading to respiratory issues and poor bird performance. Dry litter improves comfort and absorption, reducing footpad dermatitis and supporting better overall flock health. Effective bedding management involves maintaining dry litter through proper ventilation and regular cleaning to optimize poultry welfare and productivity.

Table of Comparison

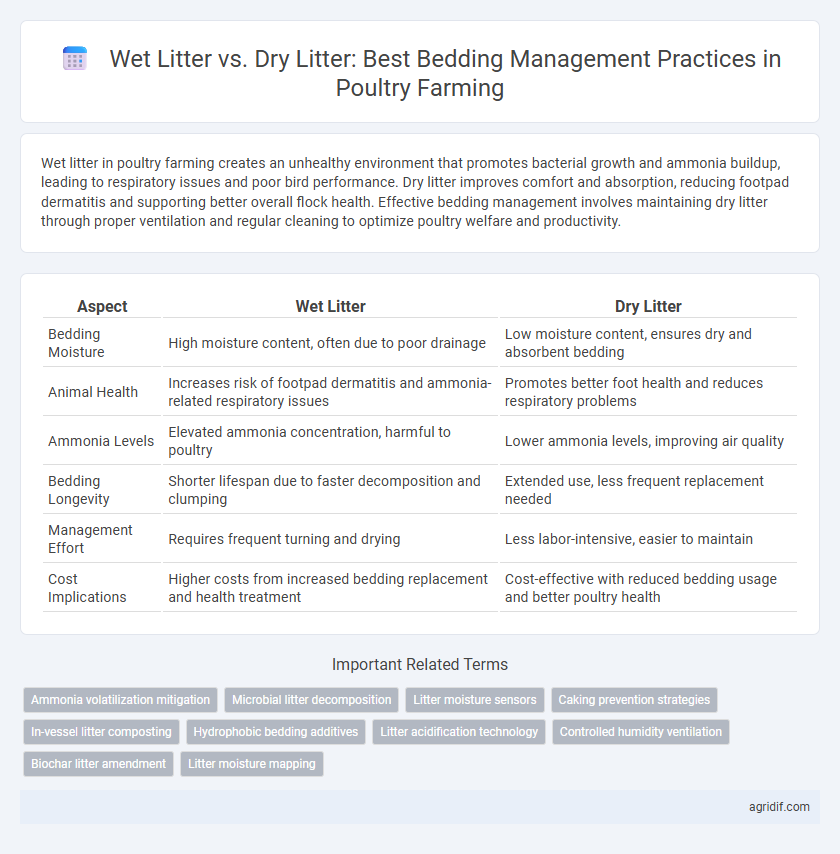

| Aspect | Wet Litter | Dry Litter |

|---|---|---|

| Bedding Moisture | High moisture content, often due to poor drainage | Low moisture content, ensures dry and absorbent bedding |

| Animal Health | Increases risk of footpad dermatitis and ammonia-related respiratory issues | Promotes better foot health and reduces respiratory problems |

| Ammonia Levels | Elevated ammonia concentration, harmful to poultry | Lower ammonia levels, improving air quality |

| Bedding Longevity | Shorter lifespan due to faster decomposition and clumping | Extended use, less frequent replacement needed |

| Management Effort | Requires frequent turning and drying | Less labor-intensive, easier to maintain |

| Cost Implications | Higher costs from increased bedding replacement and health treatment | Cost-effective with reduced bedding usage and better poultry health |

Understanding Wet Litter and Dry Litter in Poultry Farming

Wet litter in poultry farming refers to bedding material saturated with moisture from water spillage, feces, or high humidity, promoting bacterial growth and increasing the risk of footpad dermatitis and respiratory issues. Dry litter maintains optimal moisture levels below 30%, providing a comfortable environment that supports bird health, feed conversion, and overall performance. Effective litter management involves controlling ventilation, water systems, and stocking density to prevent wet litter buildup and ensure dry, absorbent bedding.

Causes of Wet Litter in Poultry Houses

Wet litter in poultry houses primarily results from excessive moisture due to water spills from drinkers, high humidity levels, or inadequate ventilation. Poor drainage and wet floor surfaces exacerbate the problem, promoting bacterial growth and increasing the risk of footpad dermatitis in broilers. Improper management of bird density and litter material also contributes to moisture retention, leading to damp bedding conditions.

Benefits of Maintaining Dry Litter Conditions

Maintaining dry litter in poultry farming significantly reduces the risk of bacterial growth, enhancing bird health and production quality. Dry litter improves air quality by minimizing ammonia levels, which supports respiratory health in flocks and reduces mortality rates. Furthermore, it promotes better footpad condition, preventing lesions and improving overall animal welfare and productivity.

Impact of Wet Litter on Poultry Health

Wet litter in poultry farming creates a humid environment that fosters the growth of harmful bacteria such as E. coli and Salmonella, increasing the risk of infections in birds. Persistent exposure to wet litter causes footpad dermatitis and respiratory issues, leading to decreased overall flock health and productivity. Maintaining dry litter is critical to minimizing disease outbreaks and improving poultry welfare and performance.

Effects of Litter Moisture on Broiler Performance

Litter moisture levels critically impact broiler performance, with wet litter increasing the risk of footpad dermatitis and hock burns, leading to reduced weight gain and feed efficiency. Dry litter promotes better air quality by minimizing ammonia emissions, which supports respiratory health and overall bird welfare. Effective moisture management through ventilation and litter turning enhances growth rates and reduces mortality in poultry farming.

Litter Management Practices to Prevent Wetness

Effective litter management practices to prevent wetness involve maintaining proper ventilation and regulating moisture levels to ensure dry bedding in poultry houses. Utilizing absorbent materials such as wood shavings or rice hulls helps reduce moisture accumulation, while regular turning and adding fresh bedding improve aeration and minimize litter caking. Consistent monitoring of water drinker systems for leaks and ensuring adequate drainage also play crucial roles in maintaining dry litter and promoting healthy poultry environments.

Recommended Bedding Materials for Dry Litter

Recommended bedding materials for dry litter in poultry farming include wood shavings, rice hulls, and sand, which provide excellent moisture absorption and promote bird comfort. Proper dry litter management reduces ammonia levels, minimizing respiratory issues and improving flock health. Consistent monitoring and maintaining optimal litter moisture below 25% ensures effective bedding performance and enhances overall poultry productivity.

Monitoring Moisture Levels in Poultry Bedding

Monitoring moisture levels in poultry bedding is crucial for maintaining optimal wet and dry litter conditions, directly impacting bird health and productivity. Wet litter increases ammonia production, promoting bacterial growth and respiratory issues, while dry litter supports better insulation and reduces pathogen proliferation. Implementing regular moisture assessments with handheld sensors or infrared technology ensures timely adjustments, preventing excessive dampness and optimizing bedding management for poultry farming success.

Cost Implications: Wet Litter vs Dry Litter Management

Wet litter management in poultry farming leads to increased costs due to frequent bedding replacement, higher labor expenses, and elevated risks of disease outbreaks requiring medical treatment. Dry litter reduces expenses by extending bedding life, minimizing health-related losses, and improving bird performance, thereby enhancing overall farm profitability. Efficient moisture control and proper ventilation are critical factors in maintaining dry litter conditions and reducing operational costs.

Sustainable Solutions for Optimal Litter Quality

Maintaining dry litter in poultry farming enhances bird health by reducing ammonia emissions and minimizing pathogen proliferation, which supports sustainable production. Wet litter management requires effective drainage systems and regular turning to prevent moisture accumulation and ensure optimal bedding quality. Sustainable solutions include using absorbent materials like rice hulls or sand and implementing controlled ventilation to maintain litter dryness and improve overall poultry welfare.

Related Important Terms

Ammonia volatilization mitigation

Dry litter in poultry bedding significantly reduces ammonia volatilization by minimizing moisture, which inhibits the microbial breakdown of uric acid into ammonia. Wet litter creates a favorable environment for ammonia production, increasing respiratory issues and decreasing overall flock health and productivity.

Microbial litter decomposition

Wet litter in poultry farming accelerates microbial litter decomposition, leading to increased ammonia production and higher pathogen proliferation, which can negatively impact bird health and housing conditions. Maintaining dry litter enhances beneficial microbial activity, reduces harmful microbial growth, and improves overall bedding quality, supporting better air quality and poultry welfare.

Litter moisture sensors

Litter moisture sensors provide precise real-time data on wet litter conditions, enabling poultry farmers to maintain optimal bedding moisture levels and prevent ammonia buildup that harms bird health. By continuously monitoring dry litter status, these sensors help improve ventilation management and reduce the risk of footpad dermatitis, enhancing overall farm productivity.

Caking prevention strategies

Effective bedding management in poultry farming requires maintaining dry litter to prevent caking, which can lead to increased ammonia levels and health issues. Strategies such as regular litter turning, proper ventilation, and controlled moisture inputs help sustain dry litter conditions, minimizing caking and promoting bird welfare.

In-vessel litter composting

In-vessel litter composting enhances control over moisture levels, promoting dry litter conditions that reduce ammonia emissions and pathogen proliferation in poultry bedding. Maintaining optimal dry litter through this method improves bird welfare and manure quality while accelerating composting efficiency.

Hydrophobic bedding additives

Hydrophobic bedding additives in poultry farming improve dry litter management by repelling moisture, reducing ammonia emissions, and enhancing bird comfort and health. These additives enhance bedding longevity, minimize pathogen growth, and optimize overall barn hygiene compared to wet litter conditions.

Litter acidification technology

Litter acidification technology in poultry farming lowers the pH of wet litter to inhibit ammonia production and bacterial growth, improving air quality and bird health. Maintaining dry litter with acidifying agents like alum or sodium bisulfate enhances moisture control, reduces pathogenic microbes, and optimizes bedding management for better poultry performance.

Controlled humidity ventilation

Controlled humidity ventilation in poultry farming prevents excess moisture accumulation, maintaining dry litter that reduces ammonia levels and promotes bird health. Proper management of ventilation systems balances humidity and air exchange to avoid wet litter, which can lead to bacterial growth and increased disease risk.

Biochar litter amendment

Biochar litter amendment enhances poultry bedding by improving moisture absorption and reducing wet litter issues, thereby minimizing ammonia emissions and pathogen proliferation. This dry litter management approach promotes healthier bird environments and optimizes overall poultry production efficiency.

Litter moisture mapping

Litter moisture mapping in poultry farming is crucial for managing wet litter, which promotes pathogen growth and ammonia production, adversely affecting bird health and performance. Dry litter maintains optimal moisture levels below 25%, reducing microbial proliferation and ensuring better air quality, thus enhancing overall poultry welfare and productivity.

Wet litter vs Dry litter for bedding management Infographic

agridif.com

agridif.com