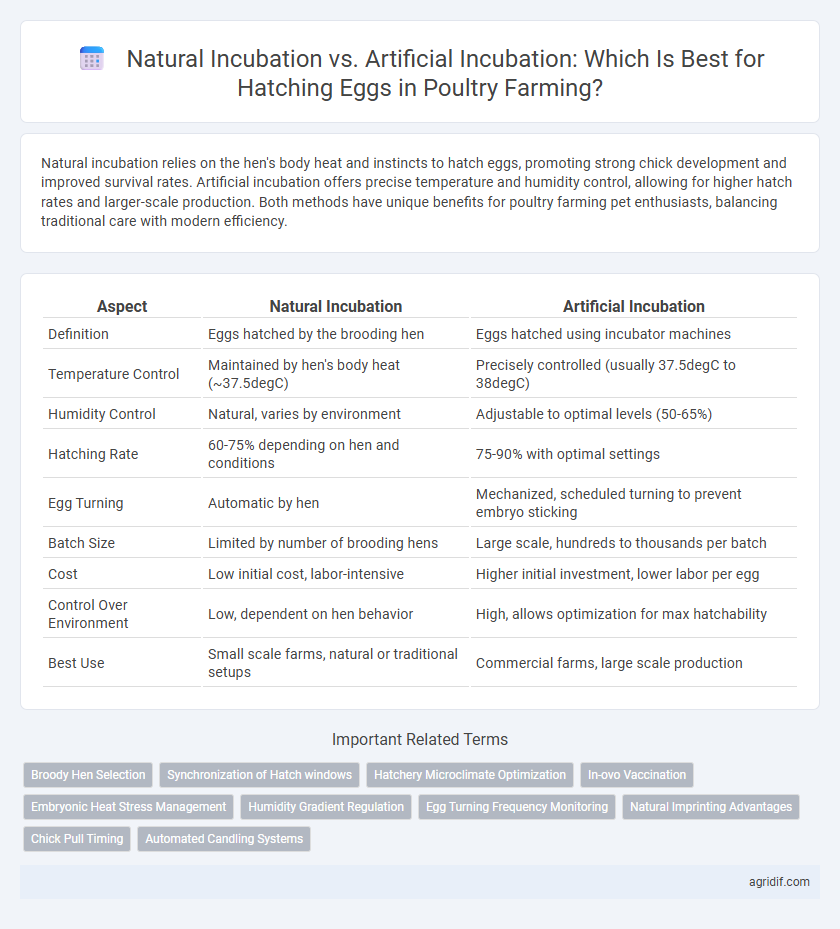

Natural incubation relies on the hen's body heat and instincts to hatch eggs, promoting strong chick development and improved survival rates. Artificial incubation offers precise temperature and humidity control, allowing for higher hatch rates and larger-scale production. Both methods have unique benefits for poultry farming pet enthusiasts, balancing traditional care with modern efficiency.

Table of Comparison

| Aspect | Natural Incubation | Artificial Incubation |

|---|---|---|

| Definition | Eggs hatched by the brooding hen | Eggs hatched using incubator machines |

| Temperature Control | Maintained by hen's body heat (~37.5degC) | Precisely controlled (usually 37.5degC to 38degC) |

| Humidity Control | Natural, varies by environment | Adjustable to optimal levels (50-65%) |

| Hatching Rate | 60-75% depending on hen and conditions | 75-90% with optimal settings |

| Egg Turning | Automatic by hen | Mechanized, scheduled turning to prevent embryo sticking |

| Batch Size | Limited by number of brooding hens | Large scale, hundreds to thousands per batch |

| Cost | Low initial cost, labor-intensive | Higher initial investment, lower labor per egg |

| Control Over Environment | Low, dependent on hen behavior | High, allows optimization for max hatchability |

| Best Use | Small scale farms, natural or traditional setups | Commercial farms, large scale production |

Introduction to Poultry Incubation Methods

Natural incubation involves hens sitting on eggs to provide consistent warmth and humidity crucial for embryo development, relying on the bird's natural behaviors and environmental conditions. Artificial incubation uses technologically controlled incubators to maintain optimal temperature, humidity, and ventilation, allowing precise management of hatching conditions and higher hatch rates. Both methods affect hatchability, chick quality, and operational scalability in poultry farming.

What is Natural Incubation?

Natural incubation involves a hen sitting on her eggs to provide consistent warmth and humidity required for embryonic development, replicating optimal environmental conditions. This natural process enables the hen to regulate temperature through her body heat and turn the eggs periodically, which is crucial for proper embryo growth. It is an energy-efficient and instinctive method but often results in lower hatch rates and less control compared to artificial incubation systems.

Understanding Artificial Incubation

Artificial incubation in poultry farming involves controlling temperature, humidity, and ventilation to optimize egg hatching conditions, achieving higher hatch rates compared to natural methods. Advanced incubators simulate the mother hen's environment, enabling large-scale, efficient production with consistent results. This technique reduces dependency on broody hens, accelerating poultry multiplication and enhancing biosecurity by minimizing disease transmission risks.

Key Differences Between Natural and Artificial Incubation

Natural incubation relies on a broody hen to provide consistent warmth, humidity, and turning of eggs, ensuring optimal embryonic development through instinctive behavior. Artificial incubation uses controlled machinery to regulate temperature, humidity, and egg turning with precision, allowing higher hatch rates and scalability. Key differences include the level of human intervention, consistency in environmental conditions, and potential hatchability rates, where artificial incubation offers more uniform and predictable outcomes compared to the variability inherent in natural methods.

Advantages of Natural Incubation in Poultry Farming

Natural incubation in poultry farming promotes stronger chick immunity by allowing gradual exposure to ambient bacteria and pathogens, enhancing disease resistance. It conserves energy and reduces equipment costs since it relies on the hen's inherent brooding instincts without the need for electrical incubators. Natural incubation also supports optimal humidity and temperature regulation, as hens instinctively adjust their positioning to create ideal conditions for embryo development.

Benefits of Artificial Incubation for Hatchery Efficiency

Artificial incubation enhances hatchery efficiency by providing precise control over temperature, humidity, and ventilation, ensuring optimal conditions for embryo development. This method significantly increases hatch rates and reduces the risk of disease transmission compared to natural incubation. Automated systems also enable large-scale, uniform hatching schedules, improving overall productivity and resource management in poultry farming.

Factors Affecting Hatchability in Both Methods

Hatchability in poultry farming is influenced by temperature, humidity, and ventilation, with natural incubation relying on the hen's body heat for consistent warmth, while artificial incubation uses controlled environmental settings to optimize these factors. Egg quality, including shell strength and cleanliness, significantly affects embryo development in both methods, with artificial incubation often allowing for better monitoring and adjustment to improve outcomes. The turning frequency of eggs during incubation impacts embryonic growth, as improper turning in either natural or artificial incubation can reduce hatchability rates.

Cost and Resource Comparison: Natural vs Artificial Incubation

Natural incubation in poultry farming requires minimal initial investment, relying on broody hens to provide warmth and care, which reduces electricity and equipment costs but limits scalability. Artificial incubation demands higher upfront expenses for incubators, energy consumption, and maintenance, yet offers precise control over temperature and humidity, enhancing hatch rates and enabling large-scale operations. The choice between natural and artificial incubation hinges on balancing cost-efficiency with production capacity and resource availability.

Best Practices for Successful Chick Hatching

Natural incubation relies on a broody hen's consistent warmth and humidity to ensure optimal embryo development, requiring a stable environment and minimal disturbance. Artificial incubation demands precise control of temperature (99.5degF), humidity (50-55%), and regular turning of eggs every 2-4 hours to mimic natural conditions and maximize hatch rates. Both methods benefit from cleanliness, monitoring, and managing airflow to prevent microbial contamination and ensure successful chick hatching outcomes.

Choosing the Right Incubation Method for Your Poultry Farm

Choosing the right incubation method for your poultry farm depends on factors such as flock size, resource availability, and desired hatch rate efficiency. Natural incubation offers cost-effective, low-maintenance benefits for small-scale farms, promoting natural brood behavior and chick vitality. Artificial incubation, using temperature-controlled incubators, provides precise environment regulation, higher hatchability rates, and scalability critical for commercial poultry production.

Related Important Terms

Broody Hen Selection

Selecting a broody hen with strong maternal instincts and consistent incubation behavior enhances natural incubation success by maintaining optimal temperature and humidity for egg development. In contrast, artificial incubation requires precise control of environmental factors but eliminates the variability of hen selection, allowing scalable and uniform hatching outcomes in poultry farming.

Synchronization of Hatch windows

Natural incubation typically results in a more synchronized hatch window due to consistent brood hen behavior maintaining uniform temperature and humidity levels. In contrast, artificial incubation requires precise monitoring and adjustments to mimic these conditions, often leading to slightly wider hatch windows if the equipment or protocols are not meticulously controlled.

Hatchery Microclimate Optimization

Natural incubation relies on the hen's ability to regulate temperature and humidity, creating a microclimate that promotes optimal embryo development; however, artificial incubation uses controlled environments with precise settings for temperature, humidity, and ventilation to maximize hatch rates and uniformity. Hatchery microclimate optimization in artificial systems involves continuous monitoring of incubator temperature (typically 99.5degF), relative humidity (around 55-60%), and CO2 levels to ensure ideal conditions for embryo growth and reduce mortality.

In-ovo Vaccination

In-ovo vaccination during artificial incubation enhances disease prevention by delivering vaccines directly into the embryo, improving hatchability rates compared to natural incubation methods. This technique reduces chick mortality and supports uniform immune development, making it a preferred choice in modern poultry farming for efficient biosecurity management.

Embryonic Heat Stress Management

Natural incubation provides consistent maternal warmth and humidity levels that help embryos better withstand heat stress, promoting healthier chick development. Artificial incubation allows precise control over temperature and humidity, enabling targeted management of embryonic heat stress through advanced environmental regulation technologies.

Humidity Gradient Regulation

Natural incubation relies on the hen's body to maintain an optimal humidity gradient crucial for embryo development, typically around 50-65%, ensuring proper shell moisture loss and hatchability. Artificial incubation enables precise control of humidity levels through automated systems, allowing adjustment to species-specific requirements and enhancing hatch rates by minimizing environmental fluctuations.

Egg Turning Frequency Monitoring

Natural incubation relies on the hen's instinctual egg turning, typically every 4-6 hours, ensuring even heat distribution and embryo development, while artificial incubation demands precise monitoring and automated egg turning systems set at intervals of 1-2 hours to optimize hatch rates. Advanced sensors and timers in artificial incubators enhance accuracy in egg turning frequency, reducing human error and improving overall chick viability compared to natural methods.

Natural Imprinting Advantages

Natural incubation fosters strong imprinting behaviors essential for chick survival, as the mother hen's warmth and presence stimulate instinctual bonding and social development. This natural imprinting enhances chick recognition, reduces stress, and improves long-term adaptability compared to artificial incubation methods.

Chick Pull Timing

Chick pull timing in natural incubation typically occurs 21 days after the hen begins incubation, allowing chicks to hatch and dry under the warmth of the mother for optimal development; artificial incubation, however, requires precise monitoring and extraction usually at 21 days as well, but demands controlled humidity and temperature to ensure survival and reduce early chick mortality. Proper timing in artificial incubation is critical to synchronize hatch window and chick viability, whereas natural incubation provides gradual temperature regulation and natural brooding behavior that enhances chick health and vitality.

Automated Candling Systems

Automated candling systems enhance artificial incubation by using advanced imaging technology to monitor embryo development, improving hatch rates and reducing human error. These systems provide precise data on egg viability, enabling optimized temperature and humidity control, which natural incubation methods cannot consistently achieve.

Natural Incubation vs Artificial Incubation for Hatching Infographic

agridif.com

agridif.com