Monocot seeds, characterized by a single cotyledon, generally exhibit a uniform shape and size that facilitate efficient mechanical planting in seed technology. Dicot seeds, with two cotyledons and more varied shapes, often require specialized equipment or adjustments to planting machinery to ensure precise placement and optimal germination. Understanding the structural differences between monocot and dicot seeds enhances the design of mechanical planters, improving planting accuracy and crop establishment rates.

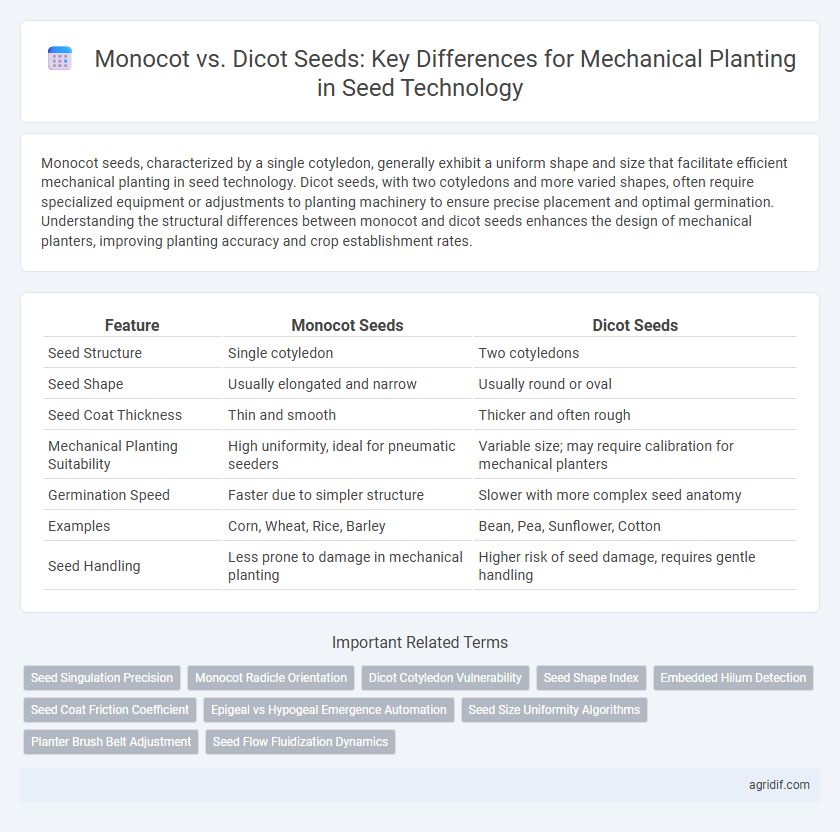

Table of Comparison

| Feature | Monocot Seeds | Dicot Seeds |

|---|---|---|

| Seed Structure | Single cotyledon | Two cotyledons |

| Seed Shape | Usually elongated and narrow | Usually round or oval |

| Seed Coat Thickness | Thin and smooth | Thicker and often rough |

| Mechanical Planting Suitability | High uniformity, ideal for pneumatic seeders | Variable size; may require calibration for mechanical planters |

| Germination Speed | Faster due to simpler structure | Slower with more complex seed anatomy |

| Examples | Corn, Wheat, Rice, Barley | Bean, Pea, Sunflower, Cotton |

| Seed Handling | Less prone to damage in mechanical planting | Higher risk of seed damage, requires gentle handling |

Introduction to Monocot and Dicot Seeds

Monocot seeds, characterized by a single cotyledon, feature parallel leaf venation and fibrous root systems that influence their ease of mechanical planting due to uniform seed size and shape. Dicot seeds possess two cotyledons, net-like leaf venation, and taproot systems, often presenting variable seed sizes and shapes which can affect seeding precision in mechanical planters. Understanding these morphological distinctions is critical for optimizing seed metering devices and planting depth control in precision agriculture systems.

Key Structural Differences Between Monocot and Dicot Seeds

Monocot seeds feature a single cotyledon that stores nutrient materials essential for seedling development, whereas dicot seeds contain two cotyledons that often serve as primary nutrient absorbers during germination. The embryo in monocots is typically encased within a protective coleoptile, enabling easier penetration through soil during mechanical planting, while dicots possess a radicle and plumule that develop more complex root and shoot systems. Seed coat thickness and rigidity differ, with monocots generally having thinner coats suited for high-speed planting equipment, compared to the often thicker and tougher coats of dicots that require calibrated seeding mechanisms.

Germination Behaviors: Monocots vs Dicots

Monocot seeds, such as maize and wheat, exhibit a single embryonic leaf that influences a uniform germination process ideal for mechanical planting systems, ensuring consistent seedling emergence. Dicot seeds like soybean and cotton possess two embryonic leaves, resulting in varied germination rates and seedling vigor, which can challenge mechanical planters due to uneven soil penetration and emergence timing. Understanding these germination behaviors enables optimization of seed placement depth and seeding equipment settings for improved crop establishment in monocots and dicots.

Seed Coat Characteristics and Mechanical Planters

Monocot seeds typically feature a thinner, less rigid seed coat compared to dicot seeds, enabling smoother passage through mechanical planters and reducing seed damage during high-speed sowing. Dicot seeds possess a thicker, tougher seed coat that requires planter settings to be adjusted for greater seed protection and precise placement to avoid breakage. Understanding these seed coat characteristics is essential for optimizing planter calibration and ensuring uniform seed distribution for both monocot and dicot crops.

Seed Size and Shape Impact on Machine Sowing

Monocot seeds, typically narrow and elongated like maize or wheat, allow for more precise mechanical sowing due to their uniform size and shape, facilitating consistent seed spacing and depth placement. Dicot seeds, such as beans or peas, often exhibit larger and more variable shapes, which can challenge seed metering systems and require specialized machinery adjustments to maintain effective sowing rates. Seed size and shape directly influence the calibration of seed drills and planters, impacting germination uniformity and overall crop yield efficiency.

Uniformity in Seedling Emergence for Monocots and Dicots

Monocot seeds exhibit higher uniformity in seedling emergence during mechanical planting due to their simple structure and consistent size, which facilitates precise seed placement and depth control. Dicot seeds, often larger and more variable in shape, can lead to uneven emergence patterns, affecting stand uniformity and crop performance. Optimizing equipment settings to accommodate these differences enhances emergence uniformity and overall planting efficiency.

Challenges of Mechanical Planting with Dicot Seeds

Mechanical planting of dicot seeds presents challenges including irregular seed shape and variable sizes, which complicate uniform seed spacing and accurate depth placement. Dicots often have larger, asymmetrical cotyledons that can cause blockages in seed metering devices designed primarily for monocots. Increased seed coat fragility in dicots risks damage during mechanical handling, reducing germination rates and crop uniformity.

Machinery Calibration for Diverse Seed Types

Mechanical planting demands precise machinery calibration to accommodate the distinct seed morphology of monocots and dicots, as monocot seeds typically exhibit a single embryonic leaf with varying sizes and shapes, while dicot seeds have two embryonic leaves with diverse texture and size profiles. Effective calibration involves adjusting seed metering systems and planting depth settings to optimize seed placement, ensuring uniform emergence and maximizing germination rates specific to each seed type. Understanding the physical and physiological differences between monocot and dicot seeds enhances planting efficiency, reduces seed damage, and improves overall crop establishment through tailored mechanical settings.

Advances in Planter Technology for Monocot and Dicot Seeds

Advances in planter technology have significantly improved seed placement accuracy and germination rates for both monocot and dicot seeds, addressing their distinct morphological differences. Precision seed meters and variable-rate planting systems optimize seed singulation for monocots like corn and wheat, which have elongated shapes, while specialized seed disks and vacuum planters accommodate the broader, irregular shapes of dicot seeds such as soybeans and peas. Enhanced sensors and AI-driven adjustments ensure consistent depth and spacing, boosting overall planting efficiency and crop yields across diverse seed types.

Best Practices for Mechanical Planting of Monocot and Dicot Crops

Effective mechanical planting of monocot and dicot seeds requires consideration of seed size, shape, and planting depth to optimize germination and emergence. Monocot seeds like maize and wheat benefit from uniform spacing and precise depth control due to their single embryonic leaf, while dicot seeds such as soybeans and beans need adjusted planter settings to accommodate their larger, irregular shapes and bilateral symmetry. Calibration of seed drills and planters for optimal seed-to-soil contact, alongside consistent seed metering and row spacing, enhances planting efficiency and crop yield in both monocot and dicot systems.

Related Important Terms

Seed Singulation Precision

Monocot seeds, typically smaller and more uniform in shape, enhance seed singulation precision in mechanical planting compared to dicot seeds, which often vary more in size and irregularity, challenging accurate spacing. Advanced seed singulation mechanisms calibrated for monocot seed morphology significantly reduce double drops and skips, optimizing planting efficiency and crop uniformity.

Monocot Radicle Orientation

Monocot seeds exhibit a radicle that is typically positioned downward, facilitating straightforward alignment and efficient penetration during mechanical planting. This consistent radicle orientation contrasts with dicot seeds, whose variable radicle position can complicate automated seeding processes and reduce planting precision.

Dicot Cotyledon Vulnerability

Dicot seeds possess two cotyledons that are often more susceptible to mechanical damage during planting due to their larger size and delicate structure. This vulnerability can lead to lower germination rates and reduced seedling vigor compared to monocot seeds, which have a single, more robust cotyledon better suited to withstand mechanical planting stresses.

Seed Shape Index

Monocot seeds typically exhibit a higher Seed Shape Index, characterized by elongated and narrow forms suitable for precision mechanical planting, whereas dicot seeds generally have a lower Seed Shape Index with broader, more irregular shapes that may challenge uniform seed placement. Optimizing seed shape parameters enhances the efficiency of mechanical planters, reducing seed damage and improving germination rates in both monocot and dicot crops.

Embedded Hilum Detection

Monocot seeds, characterized by a single cotyledon and simpler hilum structure, present fewer challenges for embedded hilum detection systems in mechanical planting compared to dicot seeds, which have two cotyledons and more complex hilum morphologies. Advanced image processing algorithms leveraging the distinct textural and spectral features of monocot hila enable higher accuracy in seed orientation and placement during automated sowing processes.

Seed Coat Friction Coefficient

Monocot seeds generally exhibit a lower seed coat friction coefficient compared to dicot seeds, facilitating smoother flow and reduced mechanical planting blockages. The higher friction coefficient of dicot seed coats often necessitates specialized equipment adjustments to optimize planting efficiency and seed placement accuracy.

Epigeal vs Hypogeal Emergence Automation

Monocot seeds typically exhibit hypogeal emergence, allowing mechanical planting systems to optimize soil coverage and reduce seedling damage, while dicot seeds generally show epigeal emergence, requiring adjustments in planting depth and machinery to accommodate their cotyledon exposure. Automation in planting must account for these differences by calibrating seed drop mechanisms and depth control to enhance germination rates and ensure uniform crop stands.

Seed Size Uniformity Algorithms

Seed size uniformity algorithms optimize mechanical planting efficiency by accurately categorizing monocot and dicot seeds based on their distinct morphological traits, such as monocots' narrow, elongated grains versus dicots' larger, rounder seeds. These algorithms enhance planter calibration and seed metering systems, reducing spatial variability and improving crop stand establishment through precise seed size discrimination.

Planter Brush Belt Adjustment

Monocot seeds, typically smaller and uniform in shape, require precise planter brush belt adjustment to ensure consistent seed spacing and avoid damage during mechanical planting. Dicot seeds, larger and often irregular in shape, necessitate looser brush tension settings for smooth seed singulation and to prevent bruising, optimizing planter efficiency and seedling emergence.

Seed Flow Fluidization Dynamics

Monocot seeds, with their uniform size and smoother surface, exhibit more consistent seed flow fluidization dynamics, enhancing mechanical planting efficiency compared to the irregular shapes and varied sizes of dicot seeds that often cause flow interruptions. Optimizing seed flow fluidization in monocots reduces blockage and promotes uniform seed spacing, critical for precise mechanical planting systems.

Monocot vs Dicot seeds for mechanical planting Infographic

agridif.com

agridif.com