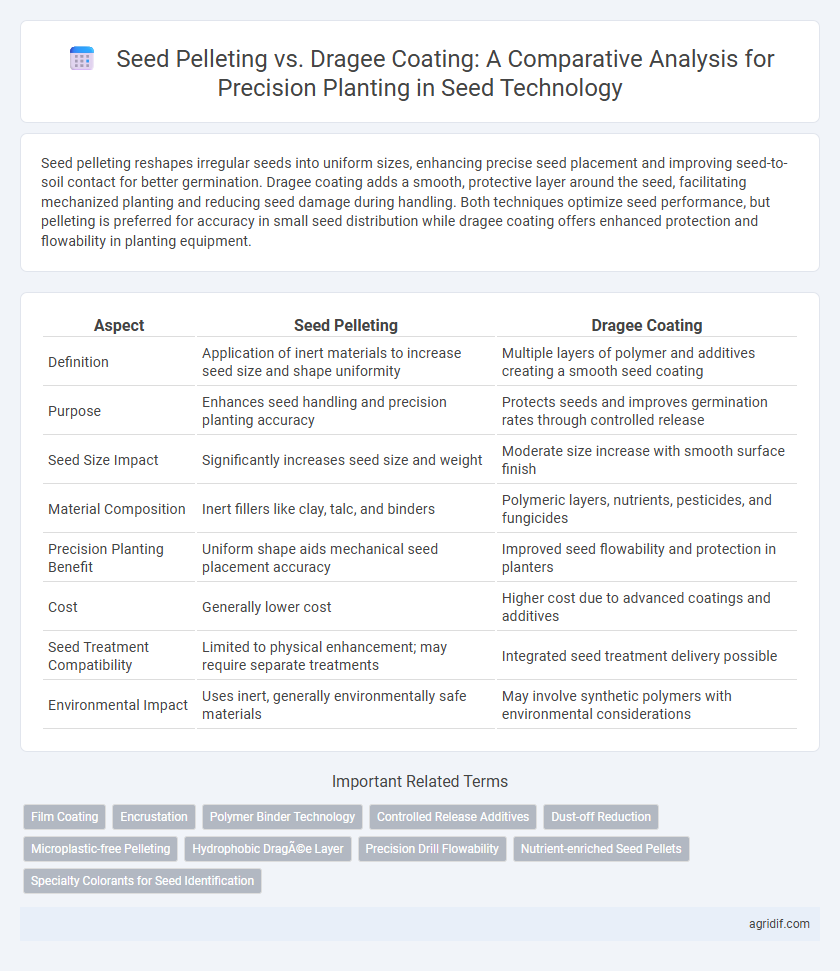

Seed pelleting reshapes irregular seeds into uniform sizes, enhancing precise seed placement and improving seed-to-soil contact for better germination. Dragee coating adds a smooth, protective layer around the seed, facilitating mechanized planting and reducing seed damage during handling. Both techniques optimize seed performance, but pelleting is preferred for accuracy in small seed distribution while dragee coating offers enhanced protection and flowability in planting equipment.

Table of Comparison

| Aspect | Seed Pelleting | Dragee Coating |

|---|---|---|

| Definition | Application of inert materials to increase seed size and shape uniformity | Multiple layers of polymer and additives creating a smooth seed coating |

| Purpose | Enhances seed handling and precision planting accuracy | Protects seeds and improves germination rates through controlled release |

| Seed Size Impact | Significantly increases seed size and weight | Moderate size increase with smooth surface finish |

| Material Composition | Inert fillers like clay, talc, and binders | Polymeric layers, nutrients, pesticides, and fungicides |

| Precision Planting Benefit | Uniform shape aids mechanical seed placement accuracy | Improved seed flowability and protection in planters |

| Cost | Generally lower cost | Higher cost due to advanced coatings and additives |

| Seed Treatment Compatibility | Limited to physical enhancement; may require separate treatments | Integrated seed treatment delivery possible |

| Environmental Impact | Uses inert, generally environmentally safe materials | May involve synthetic polymers with environmental considerations |

Introduction to Precision Planting in Seed Technology

Seed pelleting and dragee coating enhance precision planting by improving seed uniformity and handling, essential for modern agricultural efficiency. Pelleting reshapes irregular seeds for consistent sowing depth, while dragee coating adds a protective layer, optimizing seed flow in automated planters. Both techniques increase planting accuracy, reduce seed damage, and support uniform germination rates, vital for maximizing crop yields.

Overview of Seed Pelleting

Seed pelleting enhances seed size and shape by applying a uniform layer of inert materials, improving seed handling and precision planting accuracy. This technology modifies small or irregular seeds to create spherical pellets, facilitating uniform sowing depth and spacing critical for optimal crop emergence. Compared to dragee coating, pelleting prioritizes functional size alteration over decorative or protective coatings, making it ideal for precision agriculture systems.

Understanding Dragee Coating

Dragee coating involves applying multiple thin layers of polymer and protective substances to seeds, enhancing uniformity and improving seed flow for precision planting systems. This method offers superior control over seed size and shape compared to conventional seed pelleting, reducing mechanical damage during planting and ensuring consistent seed placement. Enhanced seed protection against environmental stress and pests through dragee coating leads to higher germination rates and improved crop establishment.

Key Differences: Seed Pelleting vs Dragee Coating

Seed pelleting involves encasing seeds in a uniform layer of inert material to improve size, shape, and ease of handling, optimizing seed placement in precision planting equipment. Dragee coating applies a thicker, multi-layered polymer or sugar-based outer shell, providing enhanced protection against pests, diseases, and environmental stress while potentially modifying seed release timing. Key differences include the weight and thickness of coatings, with pelleting primarily focusing on seed uniformity and mechanical sowing efficiency, whereas dragee coating emphasizes seed protection and controlled germination.

Material Composition and Application Techniques

Seed pelleting involves encapsulating seeds in a uniform layer of inert materials like clay, gypsum, and binders to enhance seed size and shape uniformity for precision planting. Dragee coating applies multiple thin layers of polymers, nutrients, and pesticides through spraying and drying cycles, creating a smooth, protective film that improves handling and germination. Differences in material composition and application techniques influence seed flowability, planting accuracy, and early seedling vigor critical for precision agriculture.

Impact on Seed Germination and Emergence

Seed pelleting enhances seed shape uniformity and facilitates precise placement in planting equipment, often improving seed-to-soil contact and promoting faster germination and uniform emergence. Dragee coating adds a protective layer that can safeguard seeds from mechanical damage and pests but may delay water uptake, sometimes resulting in slower germination rates compared to pelleted seeds. The choice between seed pelleting and dragee coating depends on crop type and field conditions, with pelleting generally preferred for precision planting due to its positive impact on early seedling development.

Influence on Precision Sowing Accuracy

Seed pelleting enhances precision sowing accuracy by standardizing seed size and shape, facilitating uniform seed placement and depth control during planting. Dragee coating, while improving seed protection and nutrient delivery, can introduce variability in seed dimensions, potentially disrupting precise meter spacing in precision planting systems. Optimizing seed pelleting protocols thus plays a critical role in reducing seed placement errors and improving overall crop uniformity in precision agriculture.

Cost-Benefit Analysis: Pelleting vs Dragee Coating

Seed pelleting offers a cost-effective solution by improving seed size uniformity and handling, reducing mechanical damage during precision planting, and enhancing germination rates without significantly increasing seed cost. Dragee coating, although more expensive due to additional materials and labor, provides superior protection against pests and diseases and allows for precise delivery of nutrients and chemicals, potentially increasing yield in high-value crops. The decision between pelleting and dragee coating depends on crop type, planting equipment compatibility, and the balance between upfront treatment costs versus expected improvements in plant establishment and overall productivity.

Environmental Considerations and Safety

Seed pelleting enhances precision planting by improving seed size uniformity, reducing dust, and minimizing chemical runoff, which lowers environmental impact and enhances operator safety. Dragee coating offers a thicker, protective layer that controls the release of agrochemicals, reducing toxic exposure and ensuring safer handling during planting. Both methods support sustainable agriculture by optimizing seed delivery while mitigating environmental contamination and health risks.

Future Trends in Seed Enhancement Technologies

Seed pelleting offers precise control over seed size and shape, enhancing uniformity for precision planting, while dragee coating provides multi-layered protection and nutrient delivery. Emerging trends emphasize integrating nanotechnology and bioactive compounds in both techniques to improve germination rates and stress resilience. Innovations in biodegradable materials for coatings aim to reduce environmental impact and support sustainable agriculture practices.

Related Important Terms

Film Coating

Film coating in seed pelleting offers a thin, uniform layer that enhances seed flowability and protects against mechanical damage, crucial for precision planting accuracy. In contrast, dragee coating provides a thicker, more protective layer but can reduce seed size uniformity and affect precise seed placement in automated planters.

Encrustation

Seed pelleting enhances seed size and shape uniformity through a thick layer of inert materials, improving mechanical handling and planting accuracy in precision agriculture. Dragee coating applies a thinner, uniform film primarily for protection and nutrient delivery, offering less impact on seed weight and size but limited seed encrustation benefits compared to pelleting.

Polymer Binder Technology

Seed pelleting uses polymer binder technology to encapsulate seeds, improving seed handling, uniform planting depth, and moisture retention for precision agriculture. Dragee coating applies multiple polymer layers to create uniform, smooth seed surfaces that enhance flowability and protect seeds during mechanical sowing, optimizing precision planting outcomes.

Controlled Release Additives

Seed pelleting enhances precision planting by uniformly shaping seeds and incorporating controlled release additives that regulate nutrient and pesticide delivery over time, optimizing seedling growth conditions. Dragee coating, while providing a protective outer layer, often results in less consistency in additive distribution and release rates, potentially reducing the effectiveness of controlled release technologies in precision agriculture applications.

Dust-off Reduction

Seed pelleting enhances dust-off reduction by encapsulating seeds with inert materials that minimize friction and prevent dust particle release during handling and sowing. Dragee coating further improves dust suppression by applying a uniform polymer layer, enabling precise planting while reducing airborne particulates and environmental contamination.

Microplastic-free Pelleting

Seed pelleting enhances precision planting by improving seed size uniformity and soil contact without relying on synthetic polymers, making microplastic-free pelleting an eco-friendly alternative to conventional dragee coating. Unlike dragee coating, which often uses plastic-based adhesives, microplastic-free pelleting employs biodegradable materials that reduce environmental contamination while maintaining seed flowability and germination rates.

Hydrophobic Dragée Layer

Hydrophobic dragee layers in seed pelleting enhance moisture resistance, improving seed protection during storage and precision planting, whereas traditional pelleting may absorb excess water and affect seed germination. This hydrophobic coating ensures uniform seed placement and optimal soil contact by preventing clumping and facilitating smoother seed flow through planting machinery.

Precision Drill Flowability

Seed pelleting enhances precision drill flowability by uniformly shaping irregular seeds, improving seed-to-soil contact and consistent placement, which is critical for precision planting. Dragee coating adds a thicker, smoother layer that can sometimes hinder seed flow through precision drills due to increased seed size and weight variability.

Nutrient-enriched Seed Pellets

Nutrient-enriched seed pellets enhance precision planting by delivering targeted micro-nutrients and growth stimulants directly to the seed, improving germination rates and early seedling vigor. In contrast, dragee coating primarily offers protective layers and uniform seed sizing without integrated nutrient benefits, making pelleting superior for optimizing seed performance in nutrient-deficient soils.

Specialty Colorants for Seed Identification

Seed pelleting enhances precision planting by uniformly shaping seeds and integrating specialty colorants for clear, durable identification, improving seed sorting and field monitoring. Dragee coating, while providing a smooth, protective outer layer, allows for vibrant specialty colorants to be applied, but may alter seed size and affect planter settings, requiring calibration for optimal precision.

Seed pelleting vs Dragee coating for precision planting Infographic

agridif.com

agridif.com