Hand reeling for silk extraction produces finer, more uniform threads that retain the natural luster of the silk, making it ideal for high-quality sericulture pets and artisanal products. Machine reeling offers faster processing and higher efficiency, yielding larger quantities of silk but often at the expense of thread strength and texture consistency. Choosing between hand and machine reeling depends on the desired silk quality and production volume for sericulture pet care and silk crafting.

Table of Comparison

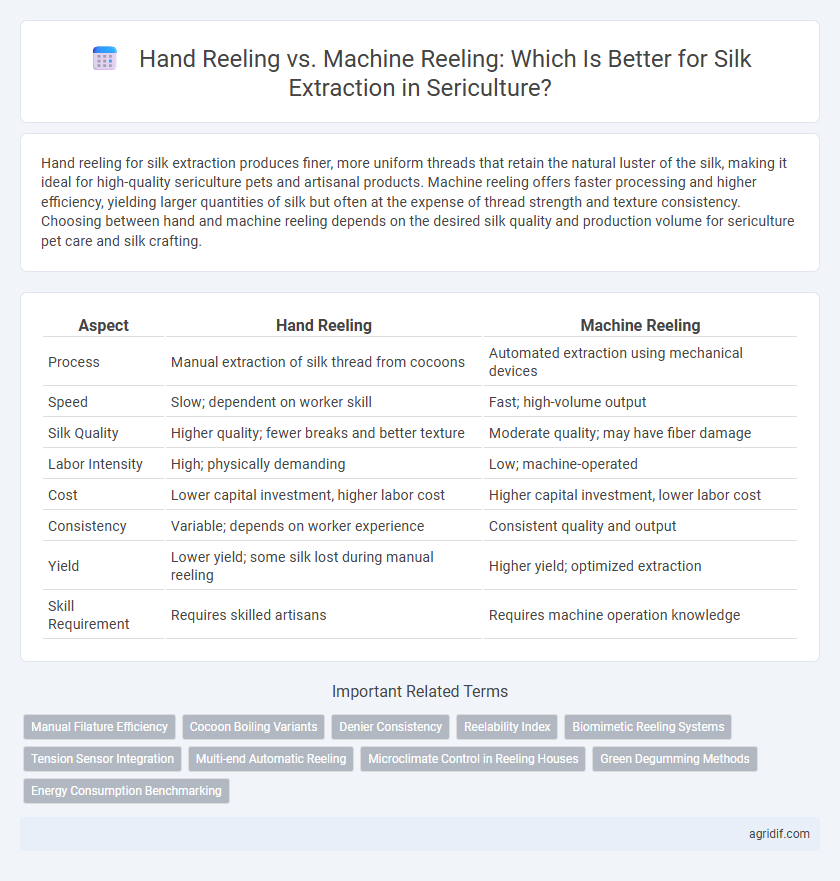

| Aspect | Hand Reeling | Machine Reeling |

|---|---|---|

| Process | Manual extraction of silk thread from cocoons | Automated extraction using mechanical devices |

| Speed | Slow; dependent on worker skill | Fast; high-volume output |

| Silk Quality | Higher quality; fewer breaks and better texture | Moderate quality; may have fiber damage |

| Labor Intensity | High; physically demanding | Low; machine-operated |

| Cost | Lower capital investment, higher labor cost | Higher capital investment, lower labor cost |

| Consistency | Variable; depends on worker experience | Consistent quality and output |

| Yield | Lower yield; some silk lost during manual reeling | Higher yield; optimized extraction |

| Skill Requirement | Requires skilled artisans | Requires machine operation knowledge |

Overview of Silk Reeling Methods

Silk reeling methods primarily include hand reeling and machine reeling, each impacting fiber quality and production efficiency. Hand reeling involves manually unwinding silk filaments from cocoons, preserving finer fiber integrity but limiting output volume. Machine reeling automates the process, enhancing speed and uniformity while potentially compromising filament length and texture due to mechanical tension.

Introduction to Hand Reeling in Sericulture

Hand reeling in sericulture involves the traditional method of extracting silk fibers manually from silkworm cocoons, ensuring delicate handling to preserve filament quality. This technique allows greater control over thread consistency and reduces fiber breakage compared to machine reeling. Despite being labor-intensive, hand reeling remains crucial for producing premium silk with superior texture and durability in artisanal silk production.

Machine Reeling Techniques: A Modern Approach

Machine reeling techniques in sericulture significantly enhance silk extraction efficiency by automating the unwinding of silk filaments from cocoons with consistent speed and tension control. Advanced machinery incorporates sensors and temperature regulation to minimize filament breakage and improve yarn uniformity, resulting in higher quality silk fabric production. These modern methods reduce labor intensity, increase throughput, and promote scalability in silk manufacturing compared to traditional hand reeling processes.

Silk Quality: Hand vs Machine Reeling

Hand reeling preserves the natural strength and luster of silk fibers by minimizing mechanical stress during extraction, resulting in higher-quality silk with superior texture and sheen. Machine reeling, while faster and more efficient, often induces fiber breakage and uneven thickness that can degrade the overall silk quality. The choice between hand and machine reeling directly impacts the tensile strength, uniformity, and market value of raw silk produced in sericulture.

Labor Requirements and Skill Involvement

Hand reeling in sericulture demands highly skilled labor familiar with delicate filament extraction, requiring significant manual dexterity and experience to maintain silk quality. Machine reeling reduces labor intensity by automating filament unwinding, allowing less skilled operators to manage the process but potentially compromising finesse in handling delicate fibers. The trade-off between labor involvement and mechanization impacts production efficiency and silk consistency, with hand reeling favored for fine silk and machines suited to large-scale output.

Production Efficiency Comparison

Hand reeling of silk yields finer, more uniform threads but suffers from lower production speed and higher labor intensity, limiting overall efficiency. Machine reeling dramatically increases output by processing larger quantities of silk cocoons rapidly while maintaining consistent thread quality, significantly boosting production rates. Despite the initial investment, machine reeling offers enhanced scalability and cost-effectiveness for large-scale sericulture operations.

Cost Analysis: Hand Reeling vs Machine Reeling

Hand reeling of silk involves lower initial capital investment but higher labor costs due to its manual nature, making it less economical for large-scale production. Machine reeling requires significant upfront investment in machinery but reduces labor expenses and increases silk extraction speed and consistency, improving overall cost efficiency. Over time, machine reeling proves more cost-effective for commercial sericulture operations by maximizing output while minimizing per-unit labor costs.

Environmental Impact of Reeling Methods

Hand reeling in sericulture generates minimal environmental impact, relying on manual techniques that consume negligible energy and produce no industrial waste. Machine reeling, while increasing efficiency and output, often involves significant electricity use and water consumption, potentially contributing to higher carbon footprints and water pollution if not managed with eco-friendly technologies. Sustainable silk production prioritizes hand reeling or eco-conscious machine operations to reduce resource depletion and environmental degradation.

Challenges Faced in Hand and Machine Reeling

Hand reeling in sericulture faces challenges such as inconsistency in silk thread thickness, lower productivity, and high dependency on skilled labor, which often leads to thread breakage and reduced fiber quality. Machine reeling, while more efficient and capable of producing uniform silk threads, encounters issues related to high initial investment costs, maintenance requirements, and the need for technical expertise for operation and troubleshooting. Both methods struggle with moisture control during reeling, which critically affects silk quality and leads to economic losses if not properly managed.

Future Prospects and Innovations in Silk Reeling

Hand reeling of silk offers precision and maintains fiber integrity, but machine reeling enhances efficiency and scalability in large-scale production. Future prospects in silk reeling focus on integrating AI-driven automation and IoT-enabled sensors to optimize fiber extraction quality and reduce waste. Innovations such as eco-friendly reeling machines and advanced robotics are poised to revolutionize sustainability and productivity in the sericulture industry.

Related Important Terms

Manual Filature Efficiency

Manual filature in sericulture offers precise control over the quality of silk fibers, enabling artisans to selectively reel fine, long filaments that enhance the fabric's texture and strength. Although slower than machine reeling, hand reeling minimizes fiber breakage and preserves the natural sheen, making it ideal for producing premium silk products.

Cocoon Boiling Variants

Hand reeling preserves the delicate structure of silk fibers by using gentle cocoon boiling methods, typically involving lower temperatures and shorter durations to maintain filament integrity. Machine reeling employs standardized high-temperature boiling variants that soften the sericin quickly, optimizing efficiency but sometimes compromising fiber uniformity and strength.

Denier Consistency

Hand reeling in sericulture often results in variable denier consistency due to manual tension control and uneven filament extraction, impacting the uniformity of silk yarn quality. Machine reeling provides precise tension regulation and consistent filament unwinding, ensuring uniform denier and higher quality silk suitable for industrial textile applications.

Reelability Index

Hand reeling offers superior control over the Reelability Index, preserving fiber strength and uniformity crucial for high-quality silk production, whereas machine reeling provides higher efficiency but may compromise the Reelability Index due to increased tension and speed variability. Optimizing the balance between reelability and throughput is essential for maximizing silk yield and maintaining filament integrity in sericulture.

Biomimetic Reeling Systems

Biomimetic reeling systems in sericulture emulate natural silkworm spinning, enhancing silk filament quality by reducing tension and breakage compared to traditional hand and machine reeling. These advanced systems optimize fiber alignment and preserve sericin layers, resulting in superior tensile strength and luster, crucial for high-value silk production.

Tension Sensor Integration

Hand reeling allows artisans to delicately manage silk filament tension, preserving fiber integrity through tactile feedback, while machine reeling increasingly integrates advanced tension sensors to automate and optimize tension control, resulting in higher consistency and reduced filament breakage. The incorporation of real-time tension sensor data in machine reeling enhances process precision, improves silk quality, and boosts overall productivity in commercial sericulture operations.

Multi-end Automatic Reeling

Multi-end automatic reeling significantly increases silk extraction efficiency by simultaneously reeling multiple filaments, ensuring uniform thread thickness and higher yield compared to traditional hand reeling. This mechanized process reduces labor intensity, improves fiber quality consistency, and accelerates production, making it essential for large-scale sericulture operations.

Microclimate Control in Reeling Houses

Hand reeling in sericulture relies on manual dexterity and is highly sensitive to microclimate variations such as temperature and humidity, impacting filament quality and reeling efficiency. Machine reeling systems, equipped with controlled microclimate technology, maintain optimal conditions consistently, enhancing silk filament uniformity and reducing defects during the extraction process.

Green Degumming Methods

Hand reeling preserves the delicate structure of silk fibers, enhancing the effectiveness of green degumming methods that utilize eco-friendly enzymes and plant-based agents, resulting in higher quality, sustainably produced silk. Machine reeling offers increased efficiency and uniformity but may slightly damage fibers, making green degumming techniques essential to maintain fiber integrity while reducing chemical waste in large-scale silk processing.

Energy Consumption Benchmarking

Hand reeling consumes significantly less energy compared to machine reeling, as it relies on manual labor without the need for electrical power or fuel. Machine reeling, while faster and more consistent, requires substantial electricity input, making it less energy-efficient in small-scale silk production settings.

Hand reeling vs Machine reeling for silk extraction Infographic

agridif.com

agridif.com