Automatic brushing for sericulture egg handling ensures consistent removal of debris and uniform cleaning, enhancing egg viability and hatching rates. Manual brushing, while allowing careful individual attention, is time-consuming and prone to inconsistency due to human error. Employing automatic brushing systems improves efficiency in large-scale sericulture operations, reducing labor costs and maintaining egg quality.

Table of Comparison

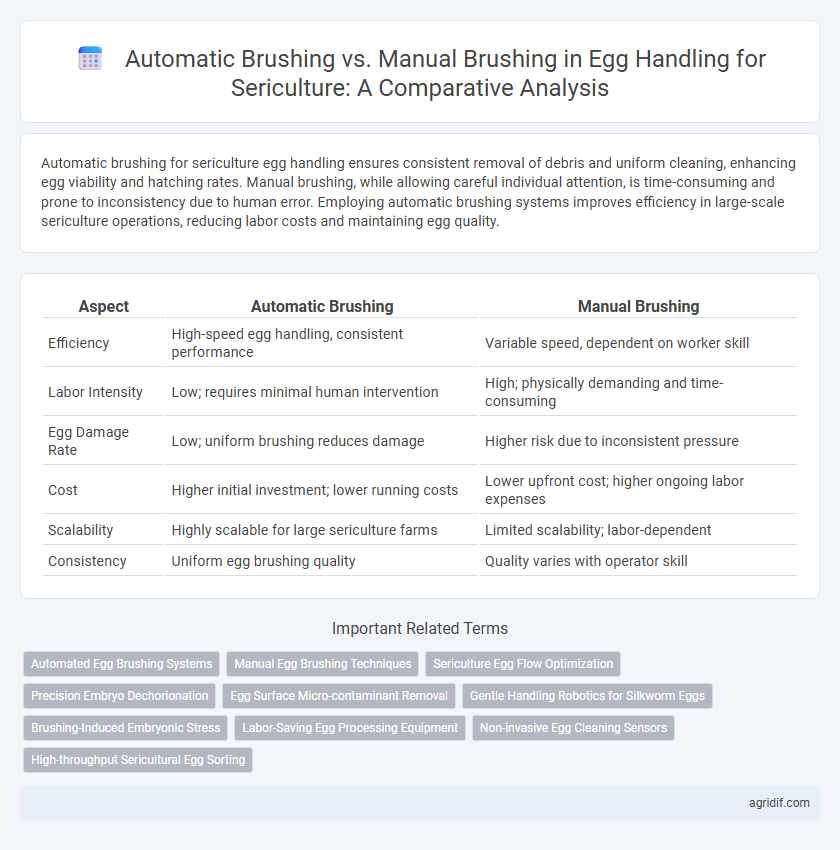

| Aspect | Automatic Brushing | Manual Brushing |

|---|---|---|

| Efficiency | High-speed egg handling, consistent performance | Variable speed, dependent on worker skill |

| Labor Intensity | Low; requires minimal human intervention | High; physically demanding and time-consuming |

| Egg Damage Rate | Low; uniform brushing reduces damage | Higher risk due to inconsistent pressure |

| Cost | Higher initial investment; lower running costs | Lower upfront cost; higher ongoing labor expenses |

| Scalability | Highly scalable for large sericulture farms | Limited scalability; labor-dependent |

| Consistency | Uniform egg brushing quality | Quality varies with operator skill |

Introduction to Egg Handling in Sericulture

Automatic brushing in sericulture enhances egg handling efficiency by reducing labor intensity and minimizing damage to silkworm eggs through consistent, gentle contact. Manual brushing requires skilled labor to carefully remove eggs from trays, but risks uneven application and higher chances of egg loss or injury. Implementing automatic systems optimizes hatch rates and streamlines the egg incubation process in sericulture operations.

Importance of Brushing in Silkworm Egg Management

Brushing plays a crucial role in silkworm egg management by ensuring proper aeration and uniform distribution of eggs to prevent clumping and fungal growth. Automatic brushing systems offer consistent pressure and speed, reducing egg damage and labor costs while enhancing hatching rates compared to manual brushing. Manual brushing allows for delicate handling but lacks the efficiency and precision of automated methods, which optimize the sericulture process through improved egg viability and productivity.

Overview of Manual Brushing Techniques

Manual brushing in sericulture involves skilled labor gently removing silkworm eggs from trays using soft brushes to avoid damage and ensure even distribution. This technique allows precise control over egg handling and is adaptable to varying egg batch sizes, though it is labor-intensive and time-consuming. Despite its slower pace, manual brushing maintains egg viability and quality, crucial for successful hatching and silkworm rearing.

Advancements in Automatic Brushing Systems

Automatic brushing systems in sericulture have revolutionized egg handling by significantly increasing efficiency and consistency compared to manual brushing, reducing labor intensity and human error. These advanced machines utilize precision brush mechanisms and controlled environments to ensure gentle and uniform egg collection, enhancing hatchability rates and overall productivity. Integration with IoT sensors further optimizes monitoring capabilities, allowing real-time adjustments and data-driven improvements in silkworm egg management.

Efficiency Comparison: Manual vs Automatic Brushing

Automatic brushing in sericulture significantly enhances egg handling efficiency by reducing labor time and ensuring uniform brushing pressure, leading to higher egg viability compared to manual brushing. Manual brushing, while allowing tactile control, is labor-intensive and prone to inconsistent strokes that can damage delicate eggs, lowering hatch rates. Studies show automatic systems improve throughput by up to 40%, optimizing silkworm egg preparation for mass production.

Impact on Egg Viability and Hatchability

Automatic brushing in sericulture ensures consistent and gentle handling of silkworm eggs, leading to higher egg viability compared to manual brushing, which can be prone to human error and inconsistent pressure. Studies show that automatic brushing significantly improves hatchability rates by minimizing mechanical damage and contamination risks. Optimized egg handling through automation enhances the overall productivity and quality of silk production.

Labor and Cost Analysis of Brushing Methods

Automatic brushing in sericulture significantly reduces labor costs by minimizing manual intervention during egg handling, leading to increased efficiency and consistency in cocoon production. Manual brushing demands skilled labor, incurring higher wages and prolonged handling times, which elevate operational expenses and increase the risk of egg damage. Cost analysis reveals that investment in automatic brushing equipment yields long-term savings through reduced labor requirements and improved egg viability, enhancing overall profitability in silk production.

Quality Control and Consistency in Egg Handling

Automatic brushing in sericulture ensures superior quality control by maintaining uniform pressure and speed during egg handling, minimizing egg damage and promoting consistent incubation results. Manual brushing often leads to variability in brush strokes and force, increasing the risk of egg damage and inconsistent hatchability rates. Advanced automatic brushing systems enhance process efficiency while delivering reliable, standardized egg handling crucial for optimal silkworm crop quality.

Challenges and Limitations of Each Method

Automatic brushing in sericulture improves efficiency and reduces labor costs but often struggles with delicate egg handling, leading to potential damage and lower hatchability rates. Manual brushing allows precise control and minimizes egg breakage, though it is labor-intensive, time-consuming, and prone to human error, limiting scalability for large-scale production. Balancing automation and manual techniques remains crucial to optimize egg viability and operational efficiency in sericulture.

Future Trends in Sericulture Egg Handling Technology

Automatic brushing in sericulture egg handling significantly enhances precision and efficiency by minimizing human error and increasing uniform egg separation, contributing to higher hatchability rates. Future trends indicate integration of AI-driven sensors and robotic arms to further optimize brushing force and speed, enabling real-time quality monitoring and adaptive adjustments. This technological evolution promises scalable solutions that reduce labor costs and improve consistency in commercial silkworm egg production.

Related Important Terms

Automated Egg Brushing Systems

Automated egg brushing systems in sericulture enhance efficiency by uniformly cleaning silkworm eggs, reducing contamination risks and minimizing labor costs compared to manual brushing methods. These systems improve hatch rates and maintain egg quality through precise control over brushing intensity and speed, ensuring consistent handling in large-scale silk production.

Manual Egg Brushing Techniques

Manual egg brushing in sericulture involves the careful use of soft brushes to gently collect and clean silkworm eggs, ensuring minimal damage and contamination. Skilled handlers control brush pressure and movement to preserve egg viability and enhance successful hatching rates compared to mechanical methods.

Sericulture Egg Flow Optimization

Automatic brushing in sericulture significantly enhances egg flow optimization by providing consistent, gentle handling that reduces egg damage and increases hatch rates compared to manual brushing, which is labor-intensive and prone to variability. Utilizing automated systems streamlines the egg collection process, improves efficiency, and ensures uniform egg distribution, critical for maintaining high-quality silkworm seed production.

Precision Embryo Dechorionation

Automatic brushing systems ensure uniform and gentle dechorionation of silkworm eggs, significantly enhancing embryo viability and hatch rates compared to manual brushing. The precision control in automated methods reduces mechanical damage and contamination risks, promoting optimal sericulture productivity.

Egg Surface Micro-contaminant Removal

Automatic brushing systems for sericulture egg handling significantly enhance the removal of micro-contaminants on the egg surface compared to manual brushing, ensuring a more uniform and controlled cleaning process. This mechanized approach reduces human error and contamination risks, thus improving the overall hygiene and viability of silkworm eggs.

Gentle Handling Robotics for Silkworm Eggs

Gentle handling robotics in sericulture offer superior precision and consistency compared to manual brushing, significantly reducing damage to silkworm eggs during handling. Automated brushing systems enhance egg viability and hatchability rates by applying controlled, uniform pressure that prevents mechanical stress and contamination.

Brushing-Induced Embryonic Stress

Automatic brushing in sericulture significantly reduces brushing-induced embryonic stress compared to manual brushing by applying consistent pressure and minimizing physical damage to silkworm eggs, leading to higher hatchability rates. Manual brushing often causes irregular mechanical stress, increasing embryo mortality and reducing silk yield due to inconsistent handling techniques.

Labor-Saving Egg Processing Equipment

Automatic brushing systems for egg handling in sericulture significantly reduce labor intensity by mechanizing the delicate process of cleaning and sorting silkworm eggs, ensuring higher efficiency and consistent quality compared to manual brushing. These labor-saving egg processing equipment minimize human error, enhance productivity, and enable large-scale operations by streamlining egg preparation while preserving egg viability.

Non-invasive Egg Cleaning Sensors

Automatic brushing systems utilize non-invasive egg cleaning sensors that detect and remove debris without damaging silkworm eggs, enhancing hatchability rates compared to manual brushing. These sensors optimize cleaning efficiency by precisely adjusting brush pressure and movement, reducing human error and ensuring uniform egg handling in sericulture.

High-throughput Sericultural Egg Sorting

Automatic brushing in high-throughput sericultural egg sorting enhances efficiency by ensuring uniform and gentle handling that reduces egg damage and contamination, leading to improved hatch rates. Manual brushing, while allowing for careful individual inspection, slows the process and increases labor costs, limiting scalability in large-scale sericulture operations.

Automatic brushing vs Manual brushing for egg handling Infographic

agridif.com

agridif.com