Automatic reeling machines offer precise control over silk thread tension and speed, resulting in uniform, high-quality yarn ideal for large-scale sericulture operations. In contrast, charkha reeling relies on manual spinning, which requires skill but provides a traditional, artisanal touch suited for small-scale or hobbyist silk producers. The choice between automatic reeling and charkha reeling impacts production efficiency, yarn consistency, and the authenticity of the final silk product.

Table of Comparison

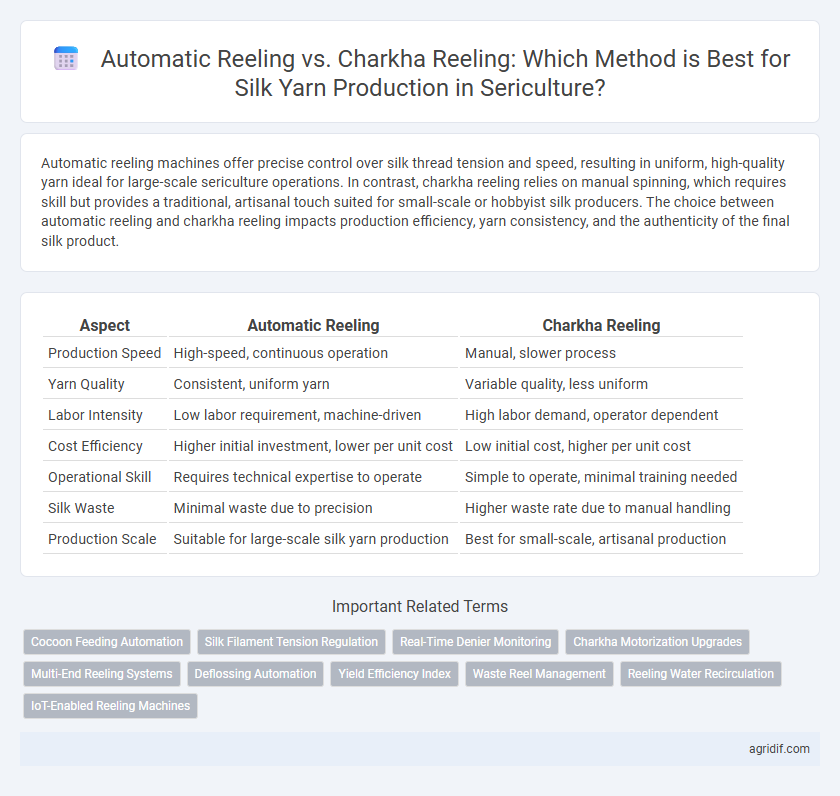

| Aspect | Automatic Reeling | Charkha Reeling |

|---|---|---|

| Production Speed | High-speed, continuous operation | Manual, slower process |

| Yarn Quality | Consistent, uniform yarn | Variable quality, less uniform |

| Labor Intensity | Low labor requirement, machine-driven | High labor demand, operator dependent |

| Cost Efficiency | Higher initial investment, lower per unit cost | Low initial cost, higher per unit cost |

| Operational Skill | Requires technical expertise to operate | Simple to operate, minimal training needed |

| Silk Waste | Minimal waste due to precision | Higher waste rate due to manual handling |

| Production Scale | Suitable for large-scale silk yarn production | Best for small-scale, artisanal production |

Introduction to Sericulture and Silk Yarn Production

Sericulture involves the cultivation of silkworms to produce silk fibers, a process key to high-quality silk yarn production. Automatic reeling machines enhance efficiency and consistency by mechanically unwinding silk filaments from cocoons, significantly increasing yield compared to traditional charkha reeling. Charkha reeling, a manual method rooted in heritage craftsmanship, allows precise control but is labor-intensive and slower, impacting large-scale silk yarn manufacturing.

Overview of Automatic Reeling and Charkha Reeling

Automatic reeling employs mechanized systems to extract silk threads from cocoons with high efficiency and consistent yarn quality, significantly increasing productivity in commercial sericulture. Charkha reeling involves manual operation using a traditional spinning wheel, offering artisanal control but lower output and variation in thread uniformity. The choice between automatic and charkha reeling impacts yarn texture, production scale, and labor intensity in silk yarn manufacturing.

Technology and Mechanism Behind Automatic Reeling

Automatic reeling technology employs sophisticated sensors and motorized spindles to precisely control the speed and tension of silk filaments, enhancing yarn uniformity and reducing breakage. This mechanized system integrates continuous filament extraction with automated monitoring, significantly increasing efficiency compared to the manual Charkha reeling method, which relies on operator skill and manual tension regulation. The advanced mechanism optimizes filament alignment and processing speed, resulting in higher quality silk yarn production with reduced labor intensity.

Traditional Charkha Reeling: Methods and Processes

Traditional Charkha reeling in sericulture involves manually unwinding silk filaments from silk cocoons using a hand-powered spinning wheel, which allows precise control over yarn thickness and texture. This method relies on skilled artisans who carefully soften the cocoons in hot water before gently extracting continuous silk threads to produce high-quality, artisanal silk yarn. Despite being labor-intensive, Charkha reeling preserves the natural luster and strength of silk, maintaining heritage craftsmanship important in many silk-producing regions.

Productivity Comparison: Automatic vs. Charkha Reeling

Automatic reeling machines significantly enhance productivity by processing silk cocoons at speeds up to 10 times faster than traditional Charkha reeling methods. While Charkha reeling offers artisanal quality control, it typically produces around 50-60 grams of silk yarn per hour compared to automatic reeling systems that yield 500-600 grams per hour. This drastic increase in output through automatic reeling supports scalable silk yarn production critical for industrial demands.

Quality of Silk Yarn: Key Differences

Automatic reeling produces silk yarn with greater uniformity and strength due to precise tension control and consistent speed, resulting in higher-grade, fault-free fibers compared to charkha reeling. Charkha reeling often leads to irregular yarn thickness and increased fiber breakage, compromising the smoothness and durability of the silk yarn. Consequently, automatic reeling is preferred in commercial silk production for its superior yarn quality and enhanced efficiency.

Cost Efficiency and Investment Analysis

Automatic reeling machines significantly reduce labor costs and increase silk yarn production speed compared to traditional charkha reeling, enhancing overall cost efficiency in sericulture. Initial investment for automatic reeling equipment is higher but offers quicker return on investment due to improved productivity and reduced wastage rates. Charkha reeling requires minimal capital expenditure, making it suitable for small-scale farmers, though its lower output and higher manual labor demand limit scalability and profit margins.

Labor Requirements and Skill Levels

Automatic reeling machines significantly reduce labor requirements by streamlining the silk yarn extraction process, enabling higher production rates with fewer workers. In contrast, Charkha reeling demands skilled artisans familiar with manual handling techniques, leading to slower output but greater control over yarn quality. The difference in skill levels directly impacts efficiency, with automatic systems favoring mechanized proficiency and Charkha relying on traditional craftsmanship.

Sustainability and Environmental Impact

Automatic reeling systems in sericulture enhance sustainability by significantly reducing water and energy consumption compared to traditional Charkha reeling methods. The mechanized process minimizes silk thread breakage and waste, promoting efficient resource utilization and lowering environmental impact. In contrast, Charkha reeling, while culturally significant, relies heavily on manual labor and produces higher variability in silk quality, often leading to increased material wastage and less sustainable practices.

Future Prospects in Sericulture: Automation vs. Tradition

Automatic reeling technology enhances silk yarn production efficiency through precision, consistent tension control, and higher output rates compared to traditional charkha reeling, which relies on manual skill and slower processing speeds. Future prospects in sericulture emphasize integrating automation to meet global silk demand, reduce labor dependency, and improve quality while preserving traditional charkha methods for niche markets valuing artisanal craftsmanship. Balancing advanced automated systems with cultural heritage enhances sustainable growth in the silk industry by leveraging both high-volume production and specialized handmade yarns.

Related Important Terms

Cocoon Feeding Automation

Automatic reeling systems enhance silk yarn production by integrating precise cocoon feeding automation, which ensures consistent tension and reduces fiber breakage compared to traditional Charkha reeling. Advanced sensors and robotic arms in automatic reels optimize cocoon placement and unwinding speed, significantly boosting efficiency and yarn quality in sericulture operations.

Silk Filament Tension Regulation

Automatic reeling systems ensure consistent silk filament tension regulation through precise mechanical controls, resulting in uniform yarn quality and minimized filament breakage. In contrast, charkha reeling relies on manual tension adjustments, often causing irregularities and uneven tension that affect the overall strength and smoothness of the silk yarn produced.

Real-Time Denier Monitoring

Automatic reeling systems enable precise real-time denier monitoring, ensuring consistent yarn thickness and enhancing silk quality by immediately detecting irregularities during production. In contrast, traditional charkha reeling lacks integrated real-time denier measurement, resulting in less uniformity and higher chances of yarn defects in silk yarn production.

Charkha Motorization Upgrades

Charkha motorization upgrades significantly enhance silk yarn production by increasing reel speed and consistency compared to traditional manual methods, improving fiber uniformity and reducing labor intensity. Automatic reeling systems excel in large-scale output and precision, yet motorized charkhas provide a cost-effective, scalable solution for small to medium sericulture enterprises.

Multi-End Reeling Systems

Multi-End Reeling Systems in automatic reeling enable simultaneous unwinding of multiple cocoons, significantly enhancing silk yarn uniformity and production efficiency compared to traditional Charkha reeling, which is manual and labor-intensive. Automated systems reduce thread breakage and improve fiber alignment, resulting in higher quality silk yarn ideal for large-scale industrial applications.

Deflossing Automation

Automatic reeling systems significantly enhance deflossing automation by efficiently removing silk waste and entangled fibers, resulting in higher quality silk yarn compared to traditional charkha reeling methods. The precision of automatic deflossing reduces manual labor and silk breakage, ensuring consistent yarn strength and smoothness essential for premium silk textile production.

Yield Efficiency Index

Automatic reeling demonstrates a significantly higher Yield Efficiency Index compared to Charkha reeling, producing up to 25% more silk yarn per cocoon due to reduced filament breakage and consistent tension control. The precision and speed of automatic machines optimize raw silk yield, making them more efficient for large-scale sericulture operations.

Waste Reel Management

Automatic reeling in sericulture significantly reduces waste reel generation by precisely controlling thread tension and speed, enhancing silk yarn uniformity and minimizing fiber breakage. In contrast, charkha reeling produces higher waste reels due to manual operation variability, leading to increased fiber wastage and lower overall yield efficiency.

Reeling Water Recirculation

Automatic reeling systems in sericulture utilize advanced water recirculation techniques that significantly reduce water consumption and improve the efficiency of silk filament extraction compared to traditional Charkha reeling, which relies on continuous fresh water flow. Efficient water recirculation in automatic reeling enhances fiber quality and sustainability by minimizing water waste and maintaining optimal temperature and cleanliness during silk yarn production.

IoT-Enabled Reeling Machines

IoT-enabled automatic reeling machines enhance silk yarn production by providing real-time monitoring and precise control over tension, temperature, and speed, resulting in higher consistency and reduced waste compared to traditional Charkha reeling. Integration of IoT sensors enables remote diagnostics and predictive maintenance, boosting efficiency and ensuring superior quality of silk yarn.

Automatic Reeling vs Charkha Reeling for Silk Yarn Production Infographic

agridif.com

agridif.com