Muga silk is renowned for its natural golden hue and durability, making it a premium choice in silk production, whereas Eri silk is prized for its softness and thermal properties, offering a versatile alternative for eco-friendly textiles. Muga silk production is limited to specific regions in India, contributing to its rarity and higher market value, while Eri silk is more widespread and easier to cultivate, supporting sustainable sericulture practices. Both silks play unique roles in the industry, with Muga silk favored for luxury apparel and Eri silk preferred for comfort and warmth.

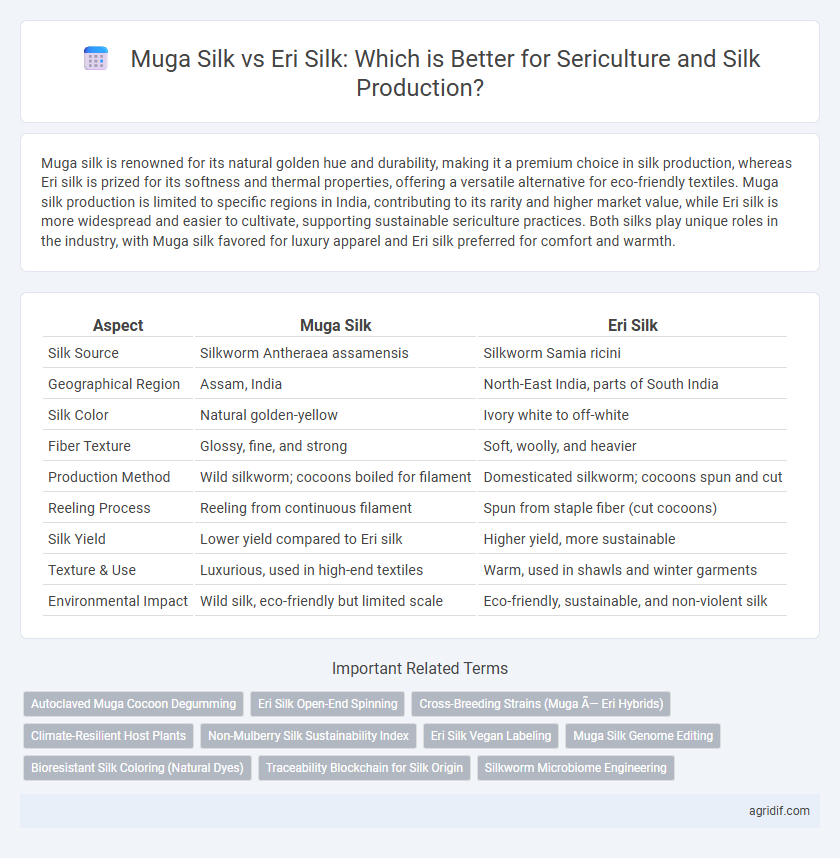

Table of Comparison

| Aspect | Muga Silk | Eri Silk |

|---|---|---|

| Silk Source | Silkworm Antheraea assamensis | Silkworm Samia ricini |

| Geographical Region | Assam, India | North-East India, parts of South India |

| Silk Color | Natural golden-yellow | Ivory white to off-white |

| Fiber Texture | Glossy, fine, and strong | Soft, woolly, and heavier |

| Production Method | Wild silkworm; cocoons boiled for filament | Domesticated silkworm; cocoons spun and cut |

| Reeling Process | Reeling from continuous filament | Spun from staple fiber (cut cocoons) |

| Silk Yield | Lower yield compared to Eri silk | Higher yield, more sustainable |

| Texture & Use | Luxurious, used in high-end textiles | Warm, used in shawls and winter garments |

| Environmental Impact | Wild silk, eco-friendly but limited scale | Eco-friendly, sustainable, and non-violent silk |

Introduction to Muga Silk and Eri Silk

Muga silk, produced primarily in Assam, India, is known for its natural golden sheen and exceptional durability, making it highly valued in luxury textile markets. Eri silk, also called Endi or Errandi silk, is derived from the castor silkworm and is prized for its soft texture and thermal insulation properties, suitable for both warm and cold climates. Both silks are eco-friendly and obtained through sericulture processes that emphasize sustainable, ethical production compared to conventional silk.

Origin and Geographical Distribution

Muga silk originates primarily from Assam, India, where the endemic Antheraea assamensis silkworm thrives in the Brahmaputra valley, renowned for producing durable, golden-hued silk. In contrast, Eri silk is predominantly produced in the northeastern states of India, including Assam and Meghalaya, using the domesticated Samia ricini silkworm, which feeds on castor leaves and generates a white or cream-colored silk. The distinct geographical distribution of Muga and Eri silk reflects their specific environmental and botanical dependencies, influencing regional sericulture economies and cultural heritage.

Silkworm Species and Host Plants

Muga silk is produced from the Antheraea assamensis silkworm species, which exclusively feeds on plants like Som (Machilus bombycina) and Sualu (Laurus nobilis), contributing to its unique golden sheen and natural durability. Eri silk, derived from the Samia ricini silkworm, primarily thrives on castor leaves (Ricinus communis), resulting in a softer, matte-textured fabric favored for its thermal insulation properties. The distinct silkworm species and their specific host plants significantly influence the characteristics and applications of Muga and Eri silk in sericulture.

Silk Production Process Comparison

Muga silk production involves harvesting cocoons from Antheraea assamensis moths, primarily in Assam, with a natural golden sheen resulting from the moths' rearing on specific host plants like Som and Sualu. Eri silk, derived from Philosamia ricini, emphasizes eco-friendly processes where larvae feed on castor leaves, and the silk is harvested after the moth emerges, resulting in spun silk rather than filament silk. The muga production process requires boiling to extract continuous filament fibers, whereas eri silk involves reeling and spinning techniques suited for its staple fiber morphology.

Physical and Chemical Properties of Muga vs Eri Silk

Muga silk exhibits a natural golden-yellow hue with superior tensile strength and elasticity compared to Eri silk, which is characterized by its off-white color and softer, more porous texture. Chemically, Muga silk contains higher fibroin content and lower sericin, contributing to its durability and glossy finish, while Eri silk's richer sericin content provides better moisture retention and thermal insulation. These distinct physical and chemical properties make Muga silk ideal for luxury textiles requiring longevity, whereas Eri silk is preferred for comfort and versatility in apparel.

Environmental Impact and Sustainability

Muga silk production has a lower environmental impact due to its reliance on wild silkworms that feed on specific host plants, preserving biodiversity and requiring minimal chemical inputs. Eri silk, often called "ahimsa silk," is produced without killing the silkworms, promoting ethical and sustainable practices while utilizing castor leaves as feed, which supports crop diversification. Both sericultures contribute to sustainable livelihoods; however, Eri silk's non-violent harvesting and Muga silk's eco-friendly cultivation methods offer distinct advantages for environmentally conscious silk production.

Economic Importance in Local Communities

Muga silk's high market value and durability boost the economic prosperity of Assam's local communities by providing premium artisanal products widely sought in luxury textiles. Eri silk, known for its affordability and ease of production, supports sustainable livelihoods in rural areas by supplying a steady income for small-scale farmers and weavers. Both sericulture types significantly contribute to regional economies by preserving traditional skills and promoting eco-friendly silk farming practices.

Application and Market Demand

Muga silk, valued for its natural golden sheen and durability, finds extensive use in high-end fashion, traditional attire, and luxury home decor, commanding premium prices due to its limited production primarily in Assam, India. Eri silk, known for its woolly texture and thermal insulation, is favored in eco-friendly textiles, winter apparel, and upholstery, appealing to a growing market focused on sustainable and versatile fabrics. Market demand for Muga silk remains niche but strong in luxury segments, while Eri silk experiences broader demand driven by sustainability trends and affordability in mainstream and artisanal markets.

Challenges in Muga and Eri Silk Cultivation

Muga silk cultivation faces challenges related to the limited geographical range of the Antheraea assamensis silkworm, which thrives only in specific climatic conditions of Assam, leading to vulnerability against environmental fluctuations and diseases. Eri silk production contends with issues in maintaining the Castor plant feedstock, as inconsistent availability and quality directly affect silkworm health and cocoon yield. Both sericulture practices require targeted pest management and improved breeding techniques to enhance productivity and silk quality under diverse agro-climatic stresses.

Future Prospects for Muga and Eri Silk Industry

Muga silk, prized for its natural golden hue and durability, holds significant promise in luxury textile markets, benefiting from increasing global demand for sustainable and eco-friendly fibers. Eri silk offers strong potential in niche markets like thermal and wellness textiles due to its warmth, softness, and hypoallergenic properties, appealing to health-conscious consumers. Both industries stand to gain from advancements in sericulture techniques, improved breed strains, and government support promoting indigenous silk production to enhance economic growth in northeastern India.

Related Important Terms

Autoclaved Muga Cocoon Degumming

Autoclaved Muga cocoon degumming preserves the unique golden luster and durability of Muga silk, enhancing fiber strength and texture compared to traditional methods used in Eri silk production. This optimized process increases protein integrity and reduces fiber damage, making autoclaved Muga silk more suitable for high-quality textile manufacturing.

Eri Silk Open-End Spinning

Eri silk, derived from the open-end spinning technique, offers a sustainable and ethical alternative to traditional muga silk production by utilizing eri silkworms that feed on castor and tapioca leaves, enabling continuous fiber extraction without killing the larvae. The open-end spinning process enhances eri silk's texture and durability, making it suitable for eco-friendly textile manufacturing and expanding its applications beyond muga silk's limited regional production.

Cross-Breeding Strains (Muga × Eri Hybrids)

Cross-breeding strains of Muga and Eri silk-producing silkworms (Antheraea assamensis x Samia ricini) enhance genetic vigor, resulting in hybrids with improved larval survival rates and cocoon yield. These Muga x Eri hybrids combine the resilience and golden luster of Muga silk with the robust texture and ease of rearing found in Eri silk, optimizing both fiber quality and production efficiency.

Climate-Resilient Host Plants

Muga silk production relies on the climate-resilient host plant Som (Machilus bombycina), which thrives in Assam's warm, humid subtropical climate, while Eri silk depends on castor leaves (Ricinus communis), adaptable to diverse climatic conditions, including xeric and semi-arid regions. The robust nature of castor plants allows Eri sericulture to be more versatile across variable environments, whereas Muga silk's dependence on specific host plant microclimates limits its cultivation to narrow climatic zones.

Non-Mulberry Silk Sustainability Index

Muga silk, produced primarily in Assam, boasts a higher Non-Mulberry Silk Sustainability Index due to its eco-friendly rearing process and minimal chemical use, enhancing biodiversity conservation. In contrast, eri silk, known for its cruelty-free extraction as it allows moth emergence, offers a sustainable alternative with a lower environmental footprint but slightly less fiber durability compared to muga silk.

Eri Silk Vegan Labeling

Eri silk, derived from the domesticated Samia ricini silkworm, is recognized for its sustainable and ethical production, earning it a vegan-friendly label as it does not involve killing the silkworm during extraction. Unlike muga silk, which is known for its natural golden sheen and limited to Assam, Eri silk offers a cruelty-free alternative widely valued in eco-conscious textile markets.

Muga Silk Genome Editing

Muga silk, produced by Antheraea assamensis, offers superior durability, natural golden luster, and resistance to extreme temperatures compared to Eri silk from Samia ricini, which is softer and more elastic. Recent advancements in genome editing techniques, particularly CRISPR-Cas9, have been applied to Muga silk to enhance traits like disease resistance and silk yield, positioning it as a promising candidate for sustainable sericulture innovation.

Bioresistant Silk Coloring (Natural Dyes)

Muga silk exhibits superior bioresistant properties to natural dyes compared to eri silk, making it more durable and vibrant for eco-friendly silk coloring processes. The higher luster and natural golden hue of muga silk enhance the absorption and retention of plant-based dyes, resulting in longer-lasting, fade-resistant textile products.

Traceability Blockchain for Silk Origin

Muga silk, prized for its natural golden hue and exclusive cultivation in Assam, contrasts with Eri silk, known for its thermal properties and ethical, non-violent harvesting. Blockchain-based traceability systems enhance the authenticity and origin verification of both Muga and Eri silk by securely recording detailed data from silkworm rearing to final fabric production, ensuring transparency and consumer trust in the sericulture supply chain.

Silkworm Microbiome Engineering

Muga silk, produced by Antheraea assamensis silkworms, exhibits a unique microbiome that enhances fiber resilience and natural golden luster, while Eri silk from Samia ricini silkworms benefits from a microbiome engineered to boost disease resistance and protein synthesis for softer, warmer silk. Targeted microbiome engineering in both species optimizes sericulture outputs by modulating gut bacteria to improve silk yield, quality, and silkworm health under varying environmental conditions.

Muga Silk vs Eri Silk for Silk Production Infographic

agridif.com

agridif.com