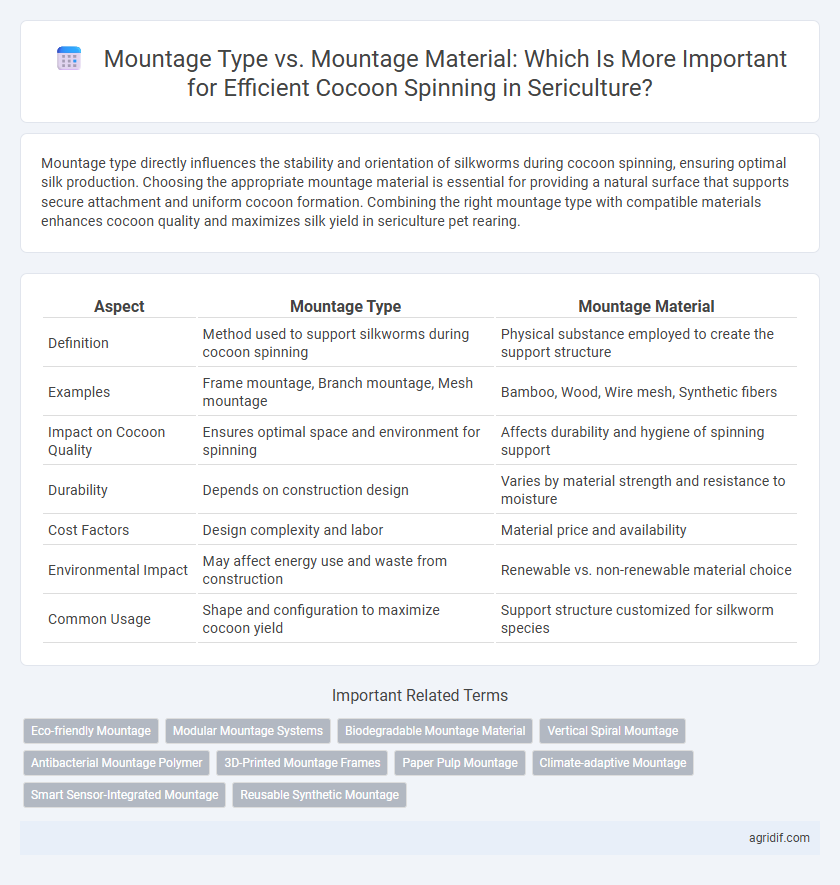

Mountage type directly influences the stability and orientation of silkworms during cocoon spinning, ensuring optimal silk production. Choosing the appropriate mountage material is essential for providing a natural surface that supports secure attachment and uniform cocoon formation. Combining the right mountage type with compatible materials enhances cocoon quality and maximizes silk yield in sericulture pet rearing.

Table of Comparison

| Aspect | Mountage Type | Mountage Material |

|---|---|---|

| Definition | Method used to support silkworms during cocoon spinning | Physical substance employed to create the support structure |

| Examples | Frame mountage, Branch mountage, Mesh mountage | Bamboo, Wood, Wire mesh, Synthetic fibers |

| Impact on Cocoon Quality | Ensures optimal space and environment for spinning | Affects durability and hygiene of spinning support |

| Durability | Depends on construction design | Varies by material strength and resistance to moisture |

| Cost Factors | Design complexity and labor | Material price and availability |

| Environmental Impact | May affect energy use and waste from construction | Renewable vs. non-renewable material choice |

| Common Usage | Shape and configuration to maximize cocoon yield | Support structure customized for silkworm species |

Understanding Mountage Types in Sericulture

Mountage types in sericulture fundamentally influence cocoon spinning efficiency by determining how silkworms attach and form cocoons. Common mountage materials include bamboo, jute, and synthetic frames, each affecting cocoon shape, size, and silk fiber quality differently. Selecting the appropriate mountage type and material enhances larval comfort and optimizes silk yield, crucial for high-quality silk production.

Common Materials Used for Cocoon Mountages

Common materials used for cocoon mountages in sericulture include bamboo, wooden frames, and wire mesh, each selected based on their durability and ease of handling. Bamboo is preferred for its lightweight and natural availability, while wooden frames offer sturdy support, especially in large-scale operations. Wire mesh is favored for its ventilation properties, promoting optimal airflow essential for healthy cocoon spinning and pupation.

Comparison: Traditional vs. Modern Mountage Types

Traditional mountage types in sericulture utilize natural materials like bamboo frames and jute ropes, offering cost-effectiveness and ease of assembly but often lack durability and uniformity. Modern mountage types employ synthetic materials such as PVC pipes and nylon nets, enhancing durability, sanitation, and scalability while improving the quality and yield of silk cocoons. Comparing the two, modern mountage systems significantly optimize cocoon spinning environments, leading to higher efficiency and reduction in contamination risks compared to traditional setups.

Impact of Mountage Material on Cocoon Quality

Mountage material directly influences the aeration and humidity control during cocoon spinning, critically affecting cocoon quality in sericulture. Natural mountages like bamboo or jute promote optimal airflow, reducing moisture buildup and enhancing silk fiber strength and uniformity. Synthetic materials may restrict ventilation, increasing risks of mold and weakening cocoon structure, thus compromising overall silk yield and quality.

Durability of Different Mountage Materials

Natural bamboo mountages offer high durability and resistance to weather conditions, making them ideal for long-term cocoon spinning in sericulture. Synthetic mountage materials, such as plastic and metal, provide enhanced strength and longevity but may lack the breathable properties needed for optimal silk quality. Proper selection of mountage type influences cocoon preservation, directly impacting the yield and quality of silk production.

Cost Analysis: Mountage Types and Materials

Cost analysis in sericulture reveals that traditional bamboo mountage types generally incur lower initial expenses compared to metallic or synthetic materials, which offer enhanced durability and longevity. Bamboo mountages require frequent replacement, increasing long-term costs, while metal and synthetic options reduce maintenance but demand higher upfront investment. Evaluating lifecycle costs in sericulture helps optimize resource allocation for cocoon spinning infrastructure.

Influence of Mountage Structure on Cocoon Yield

Mountage structure significantly influences cocoon yield by affecting the stability and space available for larval spinning during sericulture. Different mountage types, such as horizontal or vertical frames, vary in their support and ventilation properties, which impact the size and quality of the cocoons produced. Optimizing mountage material, like bamboo or metal, enhances durability and environmental control, leading to improved cocoon yield and silk quality.

Eco-Friendly Mountage Materials for Sustainable Sericulture

Eco-friendly mountage materials such as bamboo, jute, and recycled paper provide sustainable alternatives for cocoon spinning in sericulture, reducing plastic waste and minimizing environmental impact. These biodegradable materials support healthier ecosystems by avoiding harmful chemical residues and promoting natural decomposition. Utilizing organic fibers enhances silk quality and aligns with green practices essential for sustainable sericulture development.

Mountage Hygiene: Material and Design Considerations

Mountage hygiene in sericulture critically depends on the choice of materials and design to prevent contamination during cocoon spinning. Materials such as stainless steel and high-grade plastics are favored for their non-porous surfaces, resistance to microbial growth, and ease of cleaning. Design considerations include smooth surfaces and minimal crevices to reduce debris accumulation and maintain sterile conditions essential for healthy silkworm development.

Recommendations for Optimal Mountage Type and Material

Selecting optimal mountage type and material for cocoon spinning significantly impacts silk yield and quality in sericulture. Natural bamboo frames combined with fine mesh netting enhance airflow and provide stable support for larvae, promoting uniform cocoon formation. Utilizing lightweight, durable materials with adequate ventilation is recommended to reduce larval mortality and improve filament length and strength.

Related Important Terms

Eco-friendly Mountage

Eco-friendly mountage in sericulture utilizes biodegradable materials such as bamboo, jute, and natural fibers, reducing environmental impact compared to traditional metal or plastic frames. This shift not only enhances sustainability but also improves cocoon quality by providing a natural, breathable environment for silkworm spinning.

Modular Mountage Systems

Modular Mountage Systems in sericulture enhance cocoon spinning efficiency by using interchangeable components that adapt to various Mountage types, improving durability and silk yield consistency. Selecting optimized Mountage materials such as eco-friendly bamboo or high-grade polymers significantly contributes to sustaining silkworm health and maximizing filament quality.

Biodegradable Mountage Material

Biodegradable mountage materials such as bamboo, jute, and banana fibers provide an eco-friendly alternative to traditional synthetic mountage types, promoting sustainable sericulture practices by reducing environmental pollution during cocoon spinning. These natural materials enhance larval attachment and cocoon productivity while decomposing naturally, thereby supporting organic silk production and minimizing waste management issues.

Vertical Spiral Mountage

Vertical Spiral Mountage offers a compact and efficient structure for cocoon spinning, maximizing space utilization and enhancing airflow during the sericulture process. The choice of mountage material, such as bamboo or metal, significantly impacts durability, insect resistance, and ease of maintenance, directly influencing the quality and yield of silk production.

Antibacterial Mountage Polymer

Antibacterial Mountage Polymers enhance cocoon spinning by providing a sterile and durable surface that prevents microbial growth, thereby improving silk quality and yield. Compared to traditional mountage materials such as bamboo or wire, these polymers offer superior hygiene, longevity, and resistance to environmental degradation, optimizing sericulture efficiency.

3D-Printed Mountage Frames

3D-printed mountage frames for cocoon spinning offer enhanced precision and customizable designs compared to traditional mountage types, enabling improved airflow and uniform cocoon arrangement. Utilizing advanced materials like biodegradable polymers in 3D printing ensures durability, environmental sustainability, and optimized silk yield during the sericulture process.

Paper Pulp Mountage

Paper pulp mountage for cocoon spinning in sericulture offers superior moisture absorption and uniform firmness compared to traditional mountage types like bamboo or plastic, enhancing the quality of filament extraction. Its porous structure provides optimal ventilation, reducing the risk of fungal growth and improving overall cocoon hygiene during the reeling process.

Climate-adaptive Mountage

Climate-adaptive mountage for cocoon spinning utilizes materials like bamboo and neem wood, enhancing ventilation and moisture regulation critical for optimal silkworm development in varying temperatures. Choosing mountage types such as adjustable bamboo frames or modular wooden mounts improves airflow and temperature control, directly influencing cocoon quality and yield in different climatic conditions.

Smart Sensor-Integrated Mountage

Smart sensor-integrated mountage in sericulture significantly enhances cocoon spinning efficiency by precisely monitoring humidity, temperature, and vibration levels, optimizing the microenvironment for silk fiber formation. This advanced mountage type outperforms traditional materials like bamboo or metal by providing real-time data, ensuring consistent cocoon quality and reducing labor-intensive manual adjustments.

Reusable Synthetic Mountage

Reusable synthetic mountage offers superior durability and consistent quality compared to traditional mountage types, enabling efficient cocoon spinning in sericulture. Its resistance to environmental degradation and ease of cleaning make it a cost-effective material, supporting sustainable silk production.

Mountage type vs Mountage material for cocoon spinning Infographic

agridif.com

agridif.com