Reeling and spinning are two primary methods for extracting silk from silkworm cocoons in sericulture. Reeling involves carefully unwinding the continuous silk filament from the cocoon, resulting in long, smooth fibers ideal for producing high-quality silk fabric. Spinning, on the other hand, uses shorter fibers broken during cocoon processing, producing stronger but less lustrous silk yarn typically used for more durable textiles.

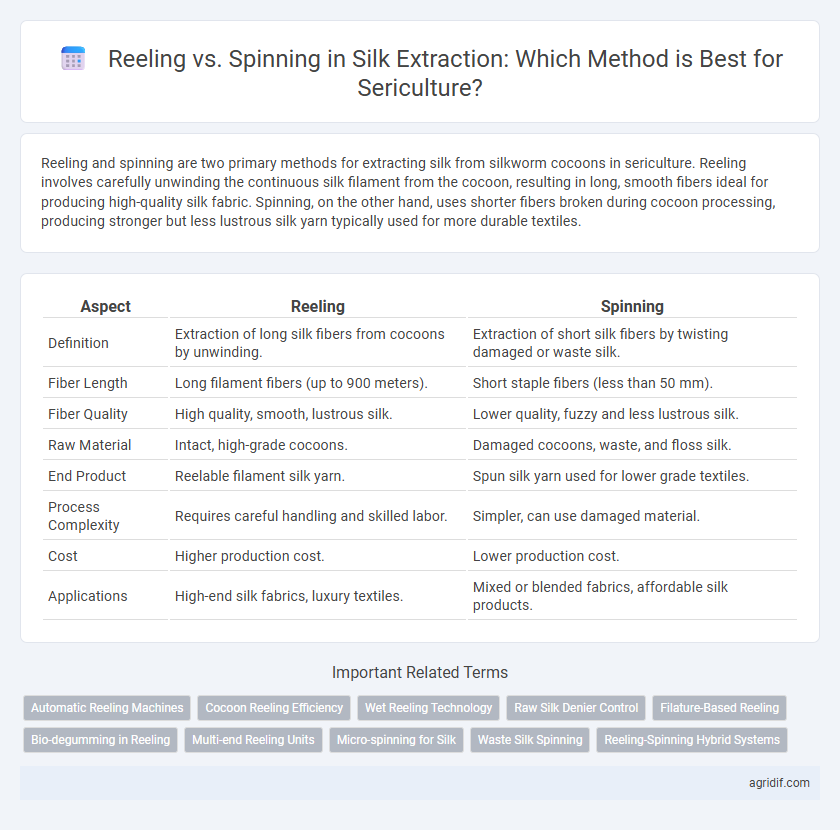

Table of Comparison

| Aspect | Reeling | Spinning |

|---|---|---|

| Definition | Extraction of long silk fibers from cocoons by unwinding. | Extraction of short silk fibers by twisting damaged or waste silk. |

| Fiber Length | Long filament fibers (up to 900 meters). | Short staple fibers (less than 50 mm). |

| Fiber Quality | High quality, smooth, lustrous silk. | Lower quality, fuzzy and less lustrous silk. |

| Raw Material | Intact, high-grade cocoons. | Damaged cocoons, waste, and floss silk. |

| End Product | Reelable filament silk yarn. | Spun silk yarn used for lower grade textiles. |

| Process Complexity | Requires careful handling and skilled labor. | Simpler, can use damaged material. |

| Cost | Higher production cost. | Lower production cost. |

| Applications | High-end silk fabrics, luxury textiles. | Mixed or blended fabrics, affordable silk products. |

Introduction to Silk Extraction Methods

Reeling and spinning are the two primary methods of silk extraction, each impacting fiber quality and end-use applications. Reeling involves unwinding silk filaments from cocoons, producing long, continuous fibers ideal for high-quality textiles. Spinning processes shorter, broken fibers or waste silk, resulting in yarns with coarser texture suited for less delicate fabric production.

Overview of Reeling and Spinning Techniques

Reeling in sericulture involves carefully unwinding silk filaments from fresh cocoons, preserving the continuous long fibers essential for high-quality silk fabric production. Spinning, by contrast, processes broken or shorter silk fibers, often obtained from damaged or waste cocoons, twisting them into yarn suitable for coarser textiles. The reeling technique yields finer, stronger silk threads, while spinning produces more affordable, diversified silk products with shorter fiber lengths.

Historical Evolution of Silk Reeling vs Spinning

Silk reeling originated in ancient China over 5,000 years ago, marking the first method of extracting long, continuous fibers directly from silk cocoons. Spinning emerged later as an alternative technique, primarily in regions lacking traditional reeling infrastructure, producing shorter fibers twisted into yarns. The historical evolution from reeling to spinning reflects technological adaptations influenced by regional resources and textile demands in the sericulture industry.

Process Workflow: Reeling Method Explained

Reeling in silk extraction involves unwinding silk filaments directly from the cocoon, preserving the continuous fiber length which ensures superior fabric strength and smoothness. The cocoon is first softened in hot water, allowing the delicate filaments to be carefully gathered onto a reel to form raw silk strands. This method contrasts with spinning, where shorter fibers are twisted together, resulting in lower tensile strength and a coarser texture.

Process Workflow: Spinning Method Explained

Spinning in sericulture involves the mechanical drawing and twisting of silk fibers to create yarn, differing from reeling which unwinds long filaments directly from cocoons. The spinning process begins with degumming to remove sericin, followed by carding to align fibers, then drafting to elongate and thin the strands before twisting them into spun silk threads. This workflow yields shorter, weaker fibers compared to reeled silk but allows utilization of damaged cocoons and waste silk for textile production.

Quality Differences in Reeled and Spun Silk

Reeled silk maintains continuous long fibers, resulting in higher tensile strength, smooth texture, and superior luster compared to spun silk, which consists of shorter, broken fibers twisted together. The uniformity in fiber length of reeled silk enhances its durability and sheen, making it ideal for high-quality textiles. In contrast, spun silk's irregular fiber composition leads to a coarser feel and lower tensile performance, often used in less delicate fabric applications.

Efficiency and Productivity Comparison

Reeling silk from cocoons yields long, continuous filaments that enhance fabric quality and maximize fiber strength, resulting in higher productivity and efficiency compared to spinning. Spinning processes shorter silk fibers by twisting them into threads, which reduces tensile strength and may lower overall fabric durability. Reeling's ability to preserve filament length directly contributes to superior silk extraction efficiency in sericulture operations.

Environmental Impact of Reeling and Spinning

Reeling silk from cocoons typically generates less environmental pollution compared to spinning, as it involves fewer chemical treatments and lower energy consumption. Spinning often relies on synthetic fibers and chemical adhesives, leading to higher carbon emissions and potential soil and water contamination. Consequently, reeling offers a more sustainable method for silk extraction by minimizing ecological footprints associated with production processes.

Economic Considerations in Silk Extraction Methods

Reeling silk from cocoons preserves filament length, resulting in higher-quality silk that commands premium market prices, while spinning uses shorter fibers and yields coarser, less valuable yarns. Reeling demands significant investment in specialized machinery and skilled labor, increasing production costs compared to the more accessible spinning process ideal for small-scale or artisanal producers. Economic viability depends on balancing upfront costs and market demand, with reeling favored in commercial sericulture for luxury textiles and spinning suited for lower-cost silk blends.

Choosing the Right Method: Factors and Recommendations

Reeling preserves the long filament fibers of silk, resulting in higher tensile strength and a smoother texture ideal for premium textiles, while spinning utilizes shorter fibers suited for coarser, more affordable silk products. Factors influencing the choice include the quality and length of raw silk fibers, intended final product characteristics, and production scale. For luxury fabrics, reeling is recommended to maintain fiber integrity, whereas spinning offers cost-effective solutions for blended or lower-grade silks.

Related Important Terms

Automatic Reeling Machines

Automatic reeling machines enhance silk extraction by efficiently unwinding silk filaments from cocoons, producing high-quality long silk fibers with minimal breakage. Compared to spinning, which involves twisting shorter fibers, automatic reeling preserves fiber length and strength, resulting in superior silk texture and luster for premium textile applications.

Cocoon Reeling Efficiency

Reeling provides higher silk filament quality and length by unwinding continuous fibers directly from the cocoon, resulting in greater cocoon reeling efficiency compared to spinning, which breaks fibers into shorter staple lengths. Cocoon reeling efficiency typically exceeds 70%, maximizing raw silk yield and minimizing fiber damage during extraction.

Wet Reeling Technology

Wet reeling technology enhances silk extraction by maintaining sericin's moisture, allowing smoother filament unwinding and higher tensile strength compared to traditional dry spinning. This process minimizes filament breakage, improves fiber uniformity, and yields superior quality silk ideal for premium textile applications.

Raw Silk Denier Control

Reeling allows precise control over raw silk denier by unwinding continuous filaments directly from silk cocoons, maintaining uniform thickness essential for high-quality textiles. In contrast, spinning involves twisting shorter silk fibers into yarn, resulting in less consistent denier and reduced smoothness compared to reeled silk.

Filature-Based Reeling

Filature-based reeling extracts long, continuous silk fibers from cocoons, preserving fiber integrity for high-quality silk production, whereas spinning processes shorter fibers into yarn, resulting in lower strength and lustre. Emphasizing filature reeling in sericulture enhances silk filament value, meeting industry standards for premium textiles.

Bio-degumming in Reeling

Reeling in silk extraction involves unwinding raw silk fibers from cocoons, preserving filament length and tensile strength while bio-degumming enhances this process by enzymatically removing sericin without harsh chemicals, improving fiber quality and environmental sustainability. In contrast, spinning processes shorter fibers into yarn after degumming, resulting in lower tensile strength and uniformity.

Multi-end Reeling Units

Multi-end reeling units significantly enhance silk fiber extraction by simultaneously unwinding multiple filaments from cocoons, leading to higher efficiency and uniform thread quality compared to traditional single-end spinning methods. This advanced reeling technology reduces yarn breakage and contamination, optimizing the sericulture value chain through improved productivity and consistent silk filament characteristics.

Micro-spinning for Silk

Micro-spinning in silk extraction offers enhanced control over fiber quality compared to traditional reeling, enabling finer filament production and minimizing breakage during processing. This technique supports sustainable sericulture by optimizing raw silk yield and improving the mechanical properties of the final silk thread.

Waste Silk Spinning

Reeling extracts long, continuous silk fibers from silk cocoons with minimal breakage, producing high-quality, lustrous silk suitable for fine textiles. Waste silk spinning processes shorter or broken fibers and damaged cocoons by carding and spinning, yielding coarser, less uniform yarns used in blended fabrics and lower-grade silk products.

Reeling-Spinning Hybrid Systems

Reeling-spinning hybrid systems combine the high-quality filament extraction of reeling with the versatility of spinning to optimize silk fiber utilization and improve overall fabric strength. These systems enable the simultaneous processing of continuous raw silk filaments and shorter silk fibers, enhancing production efficiency and expanding the range of silk-based textiles.

Reeling vs Spinning for Silk Extraction Infographic

agridif.com

agridif.com