Package rearing in sericulture offers higher productivity by providing young silkworms in disease-free, uniform batches, which enhances growth rates and cocoon quality. Traditional rearing relies on natural egg laying and hatching, often resulting in variable worm health and lower yields. Adopting package rearing techniques ensures efficient resource use and consistent silk production, making it a preferred method for modern sericulture.

Table of Comparison

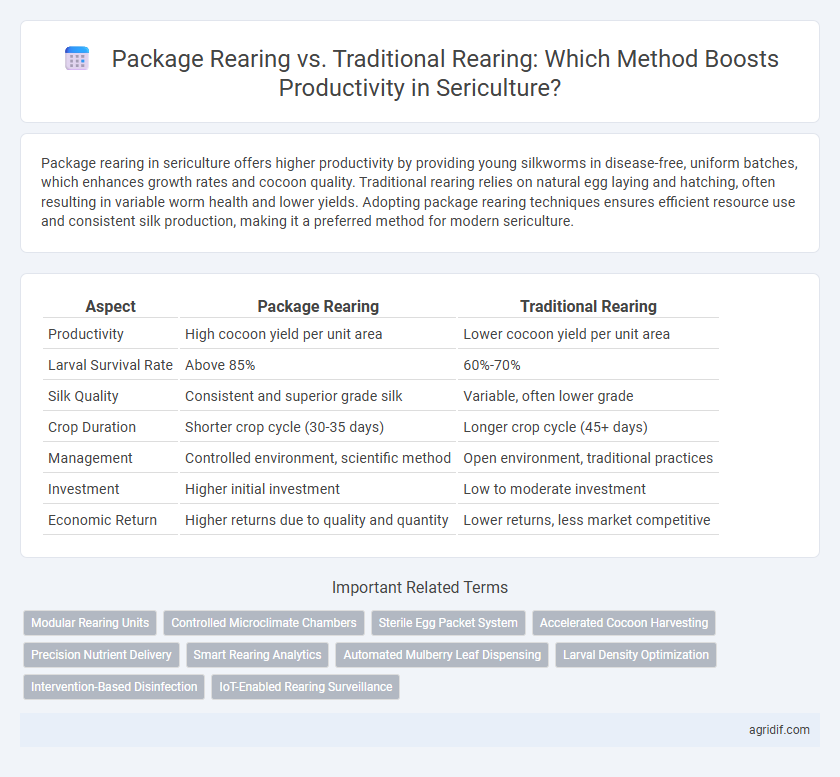

| Aspect | Package Rearing | Traditional Rearing |

|---|---|---|

| Productivity | High cocoon yield per unit area | Lower cocoon yield per unit area |

| Larval Survival Rate | Above 85% | 60%-70% |

| Silk Quality | Consistent and superior grade silk | Variable, often lower grade |

| Crop Duration | Shorter crop cycle (30-35 days) | Longer crop cycle (45+ days) |

| Management | Controlled environment, scientific method | Open environment, traditional practices |

| Investment | Higher initial investment | Low to moderate investment |

| Economic Return | Higher returns due to quality and quantity | Lower returns, less market competitive |

Overview of Sericulture Rearing Methods

Package rearing involves releasing mature silkworm eggs on trays for controlled hatching, boosting uniformity and yield, while traditional rearing allows natural egg laying on host plants, leading to varied growth and lower productivity. Package rearing optimizes resource use and minimizes disease risks through precise environmental control. In contrast, traditional methods depend heavily on farmer experience and natural conditions, often resulting in inconsistent silk production.

Defining Package Rearing in Sericulture

Package rearing in sericulture involves using disease-free, high-quality silkworm eggs or larvae enclosed in trays or boxes to ensure controlled hatching and optimal growth conditions. This method enhances productivity by minimizing larval mortality and promoting uniform development compared to traditional rearing, which relies on natural oviposition and less regulated environments. Controlled temperature, humidity, and hygiene in package rearing significantly increase silk yield and improve overall cocoon quality.

Characteristics of Traditional Rearing Techniques

Traditional rearing techniques in sericulture involve cultivating silkworms directly on mulberry leaves within open fields or simple rearing houses, relying heavily on natural environmental conditions. This method typically exhibits lower productivity due to higher exposure to predators, diseases, and fluctuations in temperature and humidity. Despite its limitations, traditional sericulture remains cost-effective and accessible for small-scale farmers with minimal infrastructure investment.

Productivity Comparison: Package vs Traditional Rearing

Package rearing significantly enhances sericulture productivity by ensuring higher survival rates and faster growth of silkworms compared to traditional methods. Controlled environments in package rearing minimize disease risks and enable multiple crops per year, resulting in increased cocoon yield and quality. Traditional rearing, reliant on natural conditions, often faces challenges like weather fluctuations and pest infestations, leading to lower and unstable silk production.

Impact on Cocoon Yield and Quality

Package rearing enhances cocoon yield by providing controlled and optimized conditions for silkworm growth, leading to higher productivity compared to traditional rearing methods. This method improves cocoon quality through uniformity in size, weight, and silk filament length, which results in superior silk texture and strength. Traditional rearing often faces challenges such as environmental unpredictability and pest infestations, reducing both yield and cocoon quality in sericulture.

Disease Management in Different Rearing Methods

Package rearing in sericulture significantly enhances disease management compared to traditional rearing by enabling controlled environments that reduce exposure to pathogens. This method facilitates regular monitoring and quicker isolation of infected larvae, minimizing the spread of diseases like pebrine and grasserie. Traditional rearing often faces challenges due to open-field conditions, increasing vulnerability to environmental factors and microbial contamination that compromise cocoon yield and quality.

Labor and Resource Efficiency

Package rearing in sericulture significantly enhances productivity by utilizing pre-cultivated silkworm eggs attached to cardboards, reducing labor intensity compared to traditional methods that require manual egg-laying and maintenance. This method optimizes resource efficiency through controlled feeding schedules and standardized environmental conditions, minimizing wastage of mulberry leaves and improving silkworm survival rates. Consequently, package rearing achieves higher cocoon yields per unit labor and resource input, driving better economic returns for sericulture producers.

Environmental Considerations in Rearing Practices

Package rearing in sericulture significantly reduces environmental degradation by minimizing land use and conserving native mulberry plants, unlike traditional rearing which often leads to deforestation and soil erosion. Controlled environments in package rearing optimize temperature and humidity, enhancing silkworm health while reducing pesticide and water consumption, promoting sustainable practices. This method supports biodiversity by limiting habitat disruption and pollution, thereby aligning sericulture productivity with ecological balance.

Cost-Benefit Analysis of Rearing Systems

Package rearing in sericulture offers higher productivity per unit area compared to traditional rearing by optimizing resource use and reducing labor costs. The initial investment in package rearing, including inoculated trays and controlled environments, is offset by increased cocoon yield and quality, enhancing profitability. Traditional rearing incurs lower startup costs but often results in variable output and higher vulnerability to environmental factors, making package rearing a cost-effective alternative in large-scale commercial sericulture.

Future Prospects in Sericulture Rearing Methods

Package rearing in sericulture offers enhanced productivity by providing controlled feeding and disease management, leading to higher silk yield compared to traditional rearing methods. Future prospects indicate a shift towards integrating advanced technologies such as automated climate control and genetic improvements in package rearing to optimize cocoon quality and reduce labor costs. Emphasis on sustainable practices within package rearing also aims to address environmental concerns, making it a promising approach for scalable sericulture development.

Related Important Terms

Modular Rearing Units

Modular rearing units in package rearing offer controlled environments that enhance silkworm health and uniformity, leading to higher cocoon yield compared to traditional rearing methods. These units optimize space and facilitate better disease management, significantly improving overall sericulture productivity.

Controlled Microclimate Chambers

Package rearing in sericulture utilizes controlled microclimate chambers to maintain optimal temperature, humidity, and ventilation, significantly enhancing silkworm growth rates and cocoon quality compared to traditional rearing methods exposed to fluctuating environmental conditions. The stable microclimate reduces disease incidence and stress in silkworms, leading to higher productivity and more consistent silk yield.

Sterile Egg Packet System

The Sterile Egg Packet System in package rearing significantly enhances sericulture productivity by ensuring controlled incubation and higher silkworm survival rates, unlike traditional rearing which often faces inconsistencies due to environmental exposure. This method streamlines larval emergence and feeding schedules, resulting in uniform growth and ultimately higher silk yield.

Accelerated Cocoon Harvesting

Package rearing in sericulture accelerates cocoon harvesting by enabling controlled, high-density silkworm cultivation that increases yield per unit time compared to traditional rearing methods. This method reduces the growth cycle and enhances productivity through optimized temperature and humidity conditions, resulting in faster and more efficient cocoon production.

Precision Nutrient Delivery

Package rearing in sericulture ensures precision nutrient delivery by providing uniform and controlled mulberry leaf portions to silkworms, enhancing larval growth and cocoon quality compared to traditional rearing. This method reduces nutrient variability and optimizes feed efficiency, leading to significantly higher silk yield and improved productivity.

Smart Rearing Analytics

Package rearing in sericulture utilizes controlled conditions and optimized feeding schedules, significantly enhancing cocoon yield and silk quality compared to traditional rearing methods. Smart rearing analytics leverage IoT sensors and data-driven insights to monitor larval health, environmental parameters, and growth patterns, enabling precise interventions that maximize productivity and reduce resource wastage.

Automated Mulberry Leaf Dispensing

Package rearing in sericulture enhances productivity by incorporating automated mulberry leaf dispensing systems that ensure consistent and optimal feeding schedules for silkworms. Traditional rearing methods rely on manual leaf feeding, which often leads to inconsistent nutrition and lower silk yield.

Larval Density Optimization

Package rearing in sericulture enhances productivity by maintaining optimal larval density, reducing competition for mulberry leaves and improving cocoon yield quality compared to traditional rearing methods. Precise control of larval density in package rearing minimizes resource wastage and disease spread, leading to more uniform growth rates and higher silk output.

Intervention-Based Disinfection

Intervention-based disinfection in package rearing significantly reduces disease incidence compared to traditional rearing, resulting in higher silk yield and improved cocoon quality. Regular sterilization of rearing trays and equipment minimizes pathogen proliferation, enhancing larval survival rates and overall productivity in sericulture.

IoT-Enabled Rearing Surveillance

IoT-enabled package rearing in sericulture significantly enhances productivity by providing real-time monitoring of environmental conditions, larval health, and feeding schedules, which traditional rearing methods lack. This advanced surveillance reduces mortality rates and optimizes growth cycles, leading to higher silk yield and improved quality.

Package Rearing vs Traditional Rearing for Productivity Infographic

agridif.com

agridif.com