Tray rearing for silkworm management offers improved hygiene and easier control over temperature and humidity, promoting healthier larval growth. Floor rearing, while traditional and cost-effective, often faces challenges with moisture retention and pest infestation, potentially affecting cocoon quality. Choosing between tray and floor rearing depends on available resources and desired silk production efficiency.

Table of Comparison

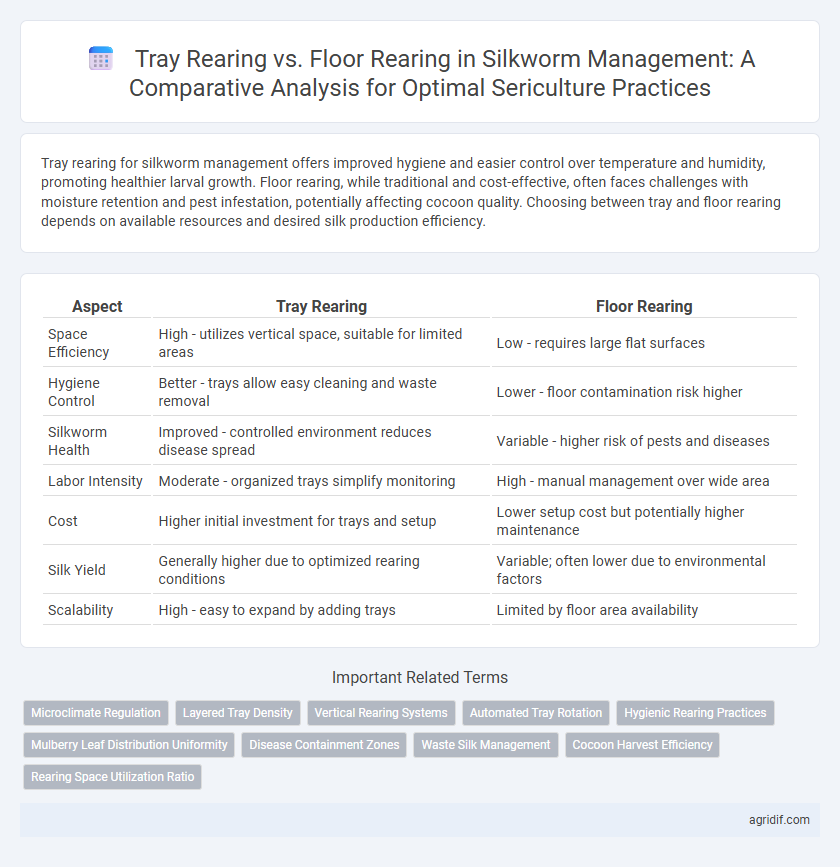

| Aspect | Tray Rearing | Floor Rearing |

|---|---|---|

| Space Efficiency | High - utilizes vertical space, suitable for limited areas | Low - requires large flat surfaces |

| Hygiene Control | Better - trays allow easy cleaning and waste removal | Lower - floor contamination risk higher |

| Silkworm Health | Improved - controlled environment reduces disease spread | Variable - higher risk of pests and diseases |

| Labor Intensity | Moderate - organized trays simplify monitoring | High - manual management over wide area |

| Cost | Higher initial investment for trays and setup | Lower setup cost but potentially higher maintenance |

| Silk Yield | Generally higher due to optimized rearing conditions | Variable; often lower due to environmental factors |

| Scalability | High - easy to expand by adding trays | Limited by floor area availability |

Introduction to Silkworm Rearing Methods

Tray rearing and floor rearing represent the two primary silkworm management techniques used in sericulture, each with distinct advantages and challenges. Tray rearing involves cultivating silkworms on raised trays, allowing for better hygiene control, efficient space utilization, and easier disease management. Floor rearing, conducted directly on beds or mats, offers traditional simplicity and cost-effectiveness but may pose higher risks of contamination and uneven environmental conditions affecting larval growth.

Overview of Tray Rearing Technique

Tray rearing is a preferred technique in sericulture that involves raising silkworms in shallow trays, facilitating better hygiene and easier pest control compared to traditional floor rearing. This method allows precise control over environmental conditions such as temperature and humidity, optimizing larval growth and cocoon quality. Enhanced aeration and waste management in tray rearing reduce disease outbreaks, leading to higher silkworm survival rates and improved silk yield.

Overview of Floor Rearing Technique

Floor rearing technique in sericulture involves placing silkworms directly on a flat, clean surface covered with mulberry leaves, facilitating easy observation and management. This method enhances air circulation around the larvae, reducing moisture buildup and minimizing disease risk compared to confined spaces. Floor rearing allows for efficient waste removal and feeding, promoting healthy growth and higher cocoon yields.

Comparative Analysis: Tray vs Floor Rearing

Tray rearing offers superior control over temperature, humidity, and hygiene, reducing disease incidence in silkworm cultivation compared to traditional floor rearing. Floor rearing provides cost-effective large-scale production but increases vulnerability to contamination and pest attacks due to limited environmental regulation. Optimal silkworm yield and cocoon quality are often higher in tray rearing systems due to precision management and ease of handling.

Environmental Control in Tray and Floor Rearing

Tray rearing offers superior environmental control by allowing precise regulation of temperature, humidity, and airflow, essential for optimizing silkworm growth and preventing diseases. Floor rearing exposes silkworms to variable microclimates and increased contamination risks due to direct contact with substrates, which can hinder consistent environmental management. Effective tray rearing systems reduce pathogenic outbreaks and enhance larval health through controlled sanitary conditions and microclimate stability.

Labor and Resource Requirements

Tray rearing in sericulture requires less labor and space compared to floor rearing, as silkworms are confined to manageable, stacked trays that simplify feeding and cleaning. Floor rearing demands more manpower and larger areas, increasing resource consumption such as mulberry leaves and maintenance efforts. Efficient labor allocation and optimized resource use make tray rearing more suitable for large-scale silkworm management.

Silkworm Health and Disease Management

Tray rearing provides controlled environmental conditions that reduce contamination and minimize the spread of diseases among silkworms, promoting better health and uniform growth. In contrast, floor rearing exposes silkworms to higher risks of bacterial and fungal infections due to poor ventilation and accumulation of waste. Effective disease management in tray rearing involves regular cleaning and disinfection protocols, which are harder to implement in floor rearing, making tray rearing the preferred method for enhancing silkworm health.

Yield and Quality of Cocoon Production

Tray rearing of silkworms offers superior control over temperature, humidity, and sanitation, directly enhancing cocoon yield and improving silk quality compared to floor rearing. Floor rearing exposes larvae to environmental fluctuations and higher contamination risks, often resulting in lower cocoon weight and compromised filament strength. Controlled microenvironments in tray rearing consistently produce denser cocoons with greater uniformity, optimizing overall sericulture productivity.

Cost-Benefit Analysis of Rearing Systems

Tray rearing of silkworms offers precise environmental control, reducing disease incidence and enhancing cocoon quality, which leads to higher market value despite initial setup costs. Floor rearing requires lower initial investment but often incurs higher labor and maintenance expenses due to manual cleaning and increased disease risk, potentially decreasing overall profitability. Cost-benefit analysis favors tray rearing for large-scale producers seeking consistent yield and quality, while floor rearing may suit small-scale operations with limited capital.

Recommendations for Optimal Silkworm Rearing

Tray rearing offers better hygiene control and disease management compared to floor rearing, making it ideal for large-scale sericulture. Maintaining optimal temperature (23-28degC) and humidity (70-85%) within trays enhances larval growth and silk quality. Regular cleaning of trays and proper ventilation are essential recommendations to prevent contamination and promote healthy silkworm development.

Related Important Terms

Microclimate Regulation

Tray rearing offers superior microclimate control by maintaining consistent temperature and humidity levels essential for optimal silkworm growth, reducing the risk of disease compared to the fluctuating conditions of floor rearing. Enhanced airflow and easier sanitation in tray rearing further stabilize the microenvironment, promoting healthier cocoon development and higher silk yield.

Layered Tray Density

Layered tray rearing optimizes space utilization by allowing higher silkworm density per square meter compared to traditional floor rearing, leading to improved airflow and reduced disease incidence. This method enhances temperature control and humidity regulation, contributing to superior cocoon quality and increased yield in sericulture.

Vertical Rearing Systems

Vertical rearing systems in sericulture optimize silkworm management by utilizing tray rearing, which enhances space efficiency and facilitates better airflow compared to traditional floor rearing methods. Tray rearing improves disease control and larval monitoring, leading to higher cocoon quality and increased silk yield in commercial silk production.

Automated Tray Rotation

Automated tray rotation in tray rearing enhances silkworm management by ensuring uniform exposure to temperature, humidity, and fresh air, significantly reducing disease incidence and improving larval growth rates compared to traditional floor rearing. This mechanized approach also optimizes space utilization and labor efficiency, leading to higher cocoon yields and better quality silk production.

Hygienic Rearing Practices

Tray rearing in silkworm management offers superior hygienic conditions by facilitating better airflow and easier removal of waste compared to floor rearing, which often leads to accumulation of debris and increased risk of disease. Enhanced cleanliness in tray systems reduces pathogen proliferation and improves larval health, resulting in higher quality silk production.

Mulberry Leaf Distribution Uniformity

Tray rearing ensures more uniform mulberry leaf distribution by providing controlled feeding spaces that minimize leaf wastage and promote even access for silkworms. Floor rearing often leads to uneven leaf distribution, resulting in competition among larvae and inconsistent growth rates due to scattered feeding areas.

Disease Containment Zones

Tray rearing of silkworms offers superior disease containment in sericulture due to isolated, controlled environments that minimize cross-contamination, whereas floor rearing increases the risk of disease spread through shared surfaces and poor ventilation. Effective tray rearing practices significantly reduce pathogen transmission in disease containment zones, improving overall silkworm health and cocoon yield.

Waste Silk Management

Tray rearing allows for more efficient waste silk management by facilitating easier collection and separation of chrysalises and excreta, reducing contamination and improving silk quality. Floor rearing often results in mixed waste that complicates silk recovery and increases the likelihood of fiber damage and lower yield.

Cocoon Harvest Efficiency

Tray rearing enhances cocoon harvest efficiency by providing a controlled environment that minimizes wastage and facilitates easier collection compared to floor rearing, which often results in higher cocoon damage and loss due to uneven distribution and contamination. Proper aeration and hygiene in tray systems optimize silkworm growth, leading to a higher yield of quality cocoons essential for sericulture productivity.

Rearing Space Utilization Ratio

Tray rearing offers a higher rearing space utilization ratio by allowing dense, organized placement of silkworms within controlled dimensions, maximizing area efficiency compared to floor rearing. Floor rearing requires more expansive space with less compact silkworm distribution, resulting in lower space utilization and potentially higher environmental exposure.

Tray Rearing vs Floor Rearing for Silkworm Management Infographic

agridif.com

agridif.com