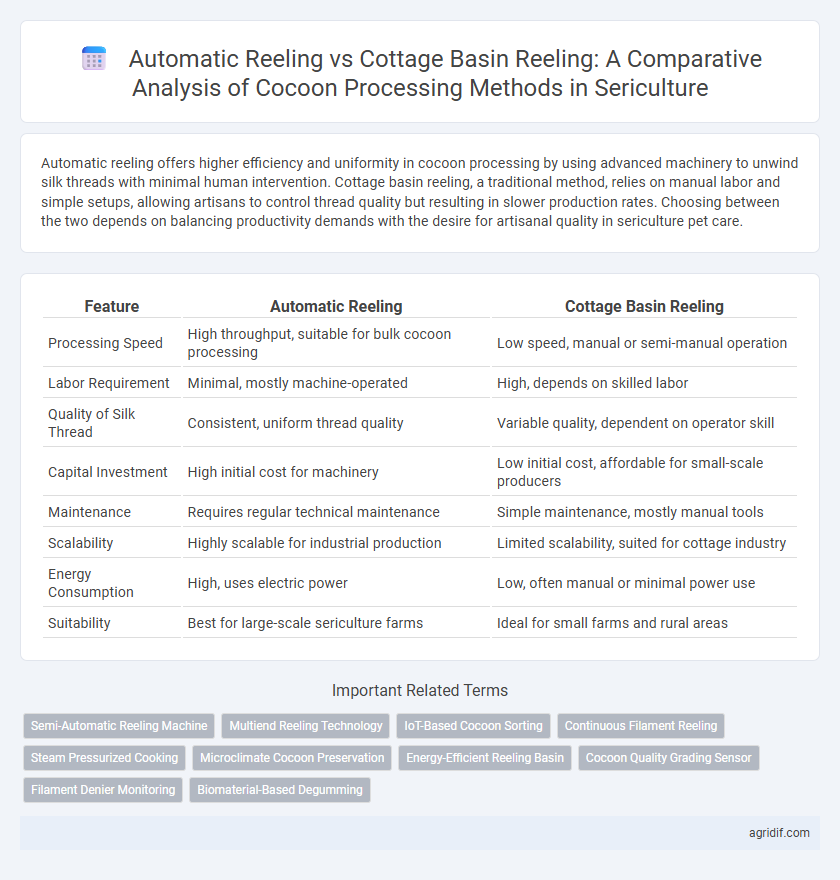

Automatic reeling offers higher efficiency and uniformity in cocoon processing by using advanced machinery to unwind silk threads with minimal human intervention. Cottage basin reeling, a traditional method, relies on manual labor and simple setups, allowing artisans to control thread quality but resulting in slower production rates. Choosing between the two depends on balancing productivity demands with the desire for artisanal quality in sericulture pet care.

Table of Comparison

| Feature | Automatic Reeling | Cottage Basin Reeling |

|---|---|---|

| Processing Speed | High throughput, suitable for bulk cocoon processing | Low speed, manual or semi-manual operation |

| Labor Requirement | Minimal, mostly machine-operated | High, depends on skilled labor |

| Quality of Silk Thread | Consistent, uniform thread quality | Variable quality, dependent on operator skill |

| Capital Investment | High initial cost for machinery | Low initial cost, affordable for small-scale producers |

| Maintenance | Requires regular technical maintenance | Simple maintenance, mostly manual tools |

| Scalability | Highly scalable for industrial production | Limited scalability, suited for cottage industry |

| Energy Consumption | High, uses electric power | Low, often manual or minimal power use |

| Suitability | Best for large-scale sericulture farms | Ideal for small farms and rural areas |

Introduction to Cocoon Processing Methods

Automatic reeling offers higher efficiency and consistent silk filament quality by mechanizing cocoon unwinding, significantly reducing labor intensity compared to traditional cottage basin reeling. Cottage basin reeling relies on manual operations with simple equipment, making it accessible for small-scale producers but prone to variability in thread uniformity and yield. Selection between these methods depends on scale, investment capacity, and desired silk quality, influencing overall sericulture productivity and market competitiveness.

Overview of Automatic Reeling Technology

Automatic reeling technology in sericulture enhances efficiency by using mechanized systems to unwind silk filaments from cocoons, significantly increasing reel speed and filament uniformity compared to traditional cottage basin reeling. This technology integrates sensors and motorized controls to maintain precise tension and filament quality, reducing labor intensity and minimizing filament breakage. The automated process supports higher production capacity and consistent silk thread quality, meeting industrial-scale demands effectively.

Cottage Basin Reeling: Traditional Approach

Cottage basin reeling is a traditional cocoon processing method where silk filaments are manually extracted from boiling cocoons in small, family-owned setups. This approach preserves the authentic texture and quality of raw silk by controlling reeling speed and tension without relying on automated machinery. Despite lower productivity compared to automatic reeling, cottage basin reeling supports local economies and maintains artisanal craftsmanship in sericulture communities.

Efficiency Comparison: Automatic vs Cottage Basin

Automatic reeling machines significantly enhance processing speed, extracting silk from cocoons at rates up to 10 times faster than cottage basin methods. The uniform mechanical action of automatic reeling ensures consistent thread diameter and higher silk filament quality, reducing waste compared to manual cottage basin reeling. While cottage basin reeling supports localized employment and low capital investment, its lower efficiency and higher labor intensity make it less suitable for large-scale commercial sericulture operations focused on maximizing output.

Quality of Silk Yarn Produced

Automatic reeling produces superior silk yarn quality with more consistent fiber thickness and reduced impurities compared to cottage basin reeling. The advanced mechanization in automatic reeling minimizes silk breakage and enhances smoothness, resulting in finer, more lustrous threads. Cottage basin reeling, being manual, often leads to irregular yarn texture and lower tensile strength, impacting the overall quality of finished silk products.

Labor Requirements and Skill Levels

Automatic reeling systems significantly reduce labor requirements by automating the cocoon processing workflow, enabling higher productivity with minimal human intervention. Cottage basin reeling relies heavily on skilled manual labor, requiring workers with specialized training to handle delicate cocoons and maintain consistent thread quality. The technical expertise needed for cottage basin methods often limits scalability, whereas automatic reeling facilitates large-scale sericulture operations through streamlined, skill-independent workflows.

Energy Consumption and Operational Costs

Automatic reeling systems exhibit significantly lower energy consumption compared to cottage basin reeling due to their efficient motor-driven mechanisms and optimized process flow. Operational costs in automatic reeling are reduced through decreased labor requirements and higher throughput, despite higher initial capital investment. Cottage basin reeling, however, incurs higher energy use and labor-intensive maintenance, leading to increased operational expenses over time.

Scalability and Commercial Viability

Automatic reeling systems offer superior scalability by enabling high-speed, continuous cocoon processing suitable for large-scale silk production, significantly increasing output compared to cottage basin reeling, which relies on labor-intensive, manual methods. Commercial viability is enhanced in automatic reeling due to reduced labor costs, consistent thread quality, and the ability to meet high market demand efficiently, whereas cottage basin reeling remains limited to small-scale operations and niche markets. Investment in automated reeling technology results in long-term profitability and growth potential, making it the preferred choice for modern sericulture enterprises.

Impact on Rural Employment and Socio-Economic Factors

Automatic reeling technology increases efficiency and production speed in cocoon processing but often reduces rural employment opportunities compared to traditional cottage basin reeling, which supports local labor and preserves artisanal skills. Cottage basin reeling contributes significantly to socio-economic stability in rural areas by providing steady income to small-scale farmers and promoting community-based sericulture practices. The shift towards automation may enhance profitability but risks marginalizing vulnerable rural workers, highlighting the need for balanced integration of modern techniques to sustain livelihoods.

Future Trends in Cocoon Reeling Techniques

Automatic reeling technology enhances productivity in cocoon processing by delivering consistent filament quality and reducing labor costs, positioning it as a key future trend for scalable sericulture operations. In contrast, cottage basin reeling remains vital for small-scale and traditional silk producers due to its low investment requirements and adaptability to local conditions. Advances in automation integration and eco-friendly materials are expected to drive innovation in both methods, promoting sustainable growth in the global silk industry.

Related Important Terms

Semi-Automatic Reeling Machine

Semi-automatic reeling machines combine the efficiency of automatic reeling with the flexibility of cottage basin reeling, optimizing cocoon processing by improving thread uniformity and reducing labor intensity. These machines enhance silk filament extraction rates by precisely controlling reel speed and tension, leading to higher quality raw silk suitable for industrial-scale production without the high initial investment of fully automatic systems.

Multiend Reeling Technology

Multiend reeling technology enhances automatic reeling by increasing efficiency and reducing silk thread breakage during cocoon processing compared to traditional cottage basin reeling, which relies on manual operation and yields lower productivity. Automatic multiend systems enable simultaneous reeling from multiple cocoons, producing uniform silk strands and improving thread quality crucial for large-scale sericulture industries.

IoT-Based Cocoon Sorting

Automatic reeling integrates IoT-based cocoon sorting to enhance precision in selecting cocoons based on quality parameters such as moisture content and filament length, significantly improving reel efficiency and fiber uniformity. Cottage basin reeling relies on manual sorting, limiting consistency and throughput, whereas IoT-driven automation enables real-time data collection and analysis, optimizing reel performance and reducing wastage in sericulture processes.

Continuous Filament Reeling

Automatic reeling systems provide precise control over tension and speed, ensuring consistent extraction of high-quality continuous filaments from cocoons, which significantly enhances silk thread uniformity and reduces waste. Cottage basin reeling, while traditional and cost-effective for small-scale production, often results in irregular filament length and lower reel speeds, limiting filament continuity and overall silk quality in large-scale sericulture operations.

Steam Pressurized Cooking

Automatic reeling with steam pressurized cooking enhances cocoon softening by maintaining consistent temperature and pressure, resulting in higher efficiency and superior silk filament quality. In contrast, cottage basin reeling relies on traditional open boiling methods, often leading to uneven cocoon cooking, lower filament strength, and reduced reel speeds.

Microclimate Cocoon Preservation

Automatic reeling systems maintain a controlled microclimate with optimal temperature and humidity, significantly reducing cocoon damage and preserving silk quality during processing. In contrast, cottage basin reeling exposes cocoons to variable environmental conditions, increasing the risk of contamination and fiber degradation.

Energy-Efficient Reeling Basin

Automatic reeling systems use advanced energy-efficient technologies, significantly reducing power consumption compared to traditional cottage basin reeling methods. These modern basins optimize temperature control and filament tension, enhancing silk quality while minimizing operational energy costs.

Cocoon Quality Grading Sensor

Automatic reeling systems equipped with cocoon quality grading sensors provide precise detection of cocoon defects such as uneven shell thickness and staining, ensuring uniform silk filament extraction and higher productivity. In contrast, cottage basin reeling relies on manual inspection, which often leads to inconsistent quality assessment and lower efficiency in sorting cocoons based on their grade.

Filament Denier Monitoring

Automatic reeling systems offer precise filament denier monitoring through integrated sensors and real-time data analytics, enabling consistent yarn quality and reducing filament breakage during cocoon processing. Cottage basin reeling relies on manual observation, leading to greater variability in filament denier and less efficient detection of irregularities, which can affect the uniformity and strength of silk threads.

Biomaterial-Based Degumming

Automatic reeling systems enhance biomaterial-based degumming efficiency by providing consistent temperature and tension control during cocoon processing, resulting in superior filament quality and reduced sericin residue. In contrast, cottage basin reeling relies on manual techniques that often cause variable degumming performance and lower fiber uniformity, impacting the biomaterial's potential for high-value silk applications.

Automatic reeling vs Cottage basin reeling for cocoon processing Infographic

agridif.com

agridif.com