Silk gland extraction involves carefully removing the silk glands from silkworms to obtain high-quality raw silk fibers with minimal impurities. Silk reeling, in contrast, is the traditional method of unwinding silk filaments directly from the cocoon, producing continuous strands essential for fabric weaving. Choosing between these techniques depends on factors like silk quality requirements, processing scale, and end-use applications in sericulture pet care.

Table of Comparison

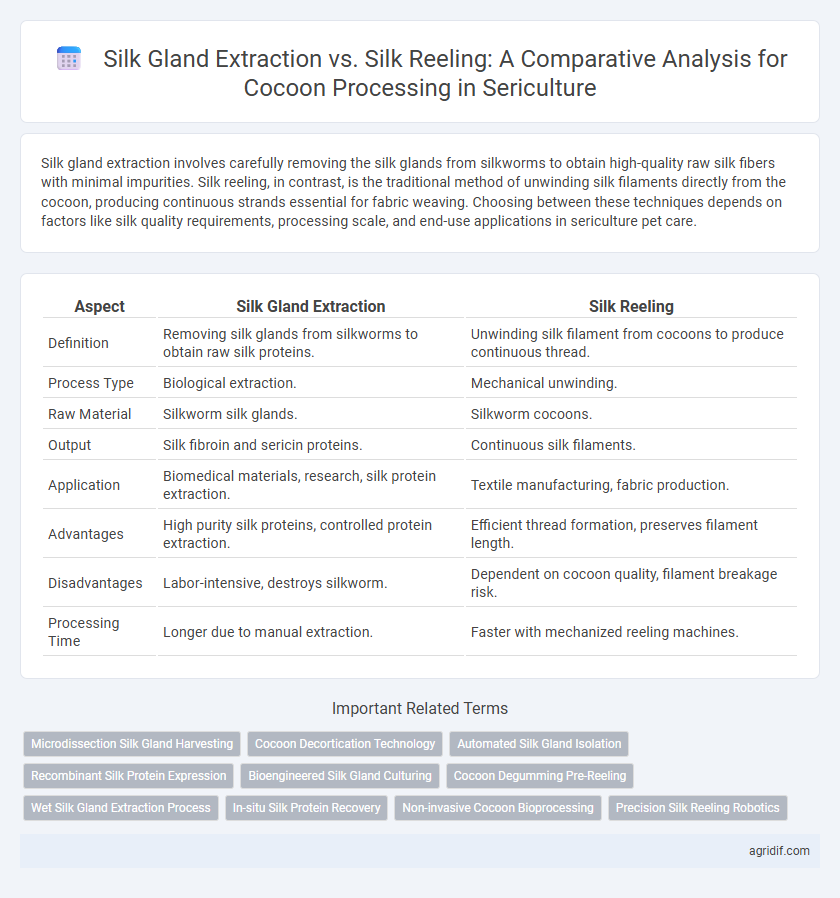

| Aspect | Silk Gland Extraction | Silk Reeling |

|---|---|---|

| Definition | Removing silk glands from silkworms to obtain raw silk proteins. | Unwinding silk filament from cocoons to produce continuous thread. |

| Process Type | Biological extraction. | Mechanical unwinding. |

| Raw Material | Silkworm silk glands. | Silkworm cocoons. |

| Output | Silk fibroin and sericin proteins. | Continuous silk filaments. |

| Application | Biomedical materials, research, silk protein extraction. | Textile manufacturing, fabric production. |

| Advantages | High purity silk proteins, controlled protein extraction. | Efficient thread formation, preserves filament length. |

| Disadvantages | Labor-intensive, destroys silkworm. | Dependent on cocoon quality, filament breakage risk. |

| Processing Time | Longer due to manual extraction. | Faster with mechanized reeling machines. |

Introduction to Sericulture: Cocoon Processing Methods

Silk gland extraction involves carefully removing the silk-producing glands from silkworms to obtain high-quality silk proteins used in biomedical and textile applications. Silk reeling, the traditional method, extracts long continuous silk fibers by unwinding cocoons in hot water, ensuring maximum fiber length and strength for textile manufacturing. Both cocoon processing methods play crucial roles in sericulture by optimizing silk yield and quality tailored to specific industrial requirements.

Silk Gland Extraction: Overview and Procedures

Silk gland extraction involves isolating the silk-producing glands from silkworm larvae before cocoon formation, enabling the production of high-quality raw silk with minimal impurities. The procedure includes dissecting larvae at a specific developmental stage, carefully removing the glands, and processing them to extract fibroin protein for advanced textile manufacturing. This method offers precise control over silk properties, improving fiber uniformity compared to traditional silk reeling from cocoons.

Silk Reeling: Traditional and Modern Techniques

Silk reeling, a critical step in cocoon processing, involves unwinding silk filaments from boiled cocoons to produce continuous silk threads, with traditional methods relying on manual labor and winders, while modern techniques employ automated reeling machines that enhance efficiency and filament quality. Advanced silk reeling technologies integrate temperature control, precise filament tensioning, and electronic sensors to minimize breakage and optimize fiber strength, significantly improving productivity compared to conventional hand reeling. The adoption of mechanized silk reeling systems supports large-scale sericulture operations by reducing labor intensity and ensuring consistent silk thread diameter, crucial for high-grade textile manufacturing.

Comparative Analysis: Yield and Efficiency

Silk gland extraction offers higher protein purity and improved control over fibroin quality, leading to superior specialized silk products, while silk reeling provides greater overall yield and faster processing efficiency ideal for mass production. The gland extraction method reduces contamination and allows selective harvesting of silk proteins, but it is labor-intensive and slower compared to the continuous and automated reel-based silk filament recovery. Industrial sericulture favors silk reeling for bulk output, whereas silk gland extraction suits niche applications requiring high-purity silk derivatives.

Quality of Silk: Extraction vs Reeling

Silk gland extraction yields higher-quality silk fibers by preserving the fibroin protein in its natural, unbroken state, resulting in smoother, stronger threads ideal for luxury textiles. Silk reeling, while more common and efficient for mass production, often produces fibers with slight breaks and irregularities due to the mechanical unwinding process, affecting the overall strength and luster of the silk. The choice between extraction and reeling significantly influences the final silk quality, with gland extraction favored for premium, high-tenacity silk products.

Economic Implications for Farmers

Silk gland extraction enables higher purity silk production but demands advanced skills and equipment, leading to increased initial investment for farmers. Silk reeling offers a cost-effective and scalable method, enhancing income potential through mass processing despite slightly lower silk quality. Economic viability for farmers depends on balancing production costs with market prices, where silk reeling often provides better short-term returns while silk gland extraction suits specialized, high-value markets.

Environmental Impact Assessment

Silk gland extraction generates less wastewater and chemical effluents compared to traditional silk reeling, which often involves water-intensive soaking processes that contribute to significant water pollution. The reduction in water use and effluent discharge during gland extraction minimizes the impact on local aquatic ecosystems and decreases soil contamination risks. Moreover, silk gland extraction's lower energy consumption reduces the overall carbon footprint, making it a more sustainable option in cocoon processing from an environmental impact perspective.

Technological Innovations in Cocoon Processing

Technological innovations in cocoon processing have significantly advanced both silk gland extraction and silk reeling techniques, enhancing efficiency and silk quality. Silk gland extraction, utilizing microdissection robotics, allows precise harvesting of silk fibroin proteins directly from silkworm glands, improving silk purity for biomedical applications. In contrast, automated silk reeling machines equipped with tension and speed sensors optimize filament unwinding from cocoons, maximizing yield and reducing waste in textile production.

Labor and Skill Requirements

Silk gland extraction demands highly skilled labor due to the delicate process of carefully removing silk glands from silkworms, ensuring the preservation of fibroin proteins for advanced biomedical applications. In contrast, silk reeling requires moderately skilled workers trained in unwinding silk threads from cocoons efficiently to produce continuous silk fibers for textile manufacturing. The labor intensity and expertise needed for gland extraction are significantly higher, limiting its scalability compared to the more mechanized and widely practiced silk reeling method.

Future Trends in Sericulture Processing

Future trends in sericulture processing emphasize automation and precision in both silk gland extraction and silk reeling techniques to enhance fiber yield and quality. Advances in genetic engineering and enzymatic treatment are expected to optimize the efficiency of silk gland extraction, facilitating the production of high-purity fibroin proteins. Meanwhile, innovations in mechanized silk reeling systems aim to reduce labor intensity and improve continuous filament recovery, crucial for meeting increasing industrial demand in textile and biomedical applications.

Related Important Terms

Microdissection Silk Gland Harvesting

Microdissection silk gland harvesting enables precise extraction of fibroin and sericin proteins critical for high-quality silk fiber production, bypassing the mechanical stress associated with conventional silk reeling. This method preserves the gland's cellular integrity, facilitating detailed molecular studies and enhancing the understanding of sericultural genetics and silk protein biosynthesis.

Cocoon Decortication Technology

Cocoon decortication technology enhances silk gland extraction by efficiently removing sericin and impurities, preserving fibroin quality for superior silk threads. Compared to traditional silk reeling, decortication improves fiber cleanliness and uniformity, boosting overall cocoon processing efficiency in sericulture.

Automated Silk Gland Isolation

Automated silk gland isolation enhances precision and efficiency compared to traditional silk reeling by enabling targeted extraction of high-quality fibroin proteins directly from silk glands, minimizing cocoon waste and preserving sericin integrity. This advanced technology streamlines cocoon processing in sericulture, boosting silk yield consistency and reducing labor-intensive manual handling.

Recombinant Silk Protein Expression

Silk gland extraction enables direct access to native fibroin proteins, facilitating efficient recombinant silk protein expression with higher purity and structural integrity compared to traditional silk reeling methods that primarily harvest fibroin fibers from spun cocoons. This targeted extraction enhances the yield of functional recombinant proteins crucial for biotechnological and medical applications in sericulture.

Bioengineered Silk Gland Culturing

Silk gland extraction enables the harvest of fibroin proteins directly from bioengineered silk glands, preserving molecular integrity critical for advanced biomaterial applications. Silk reeling, while efficient for traditional cocoon processing, often results in fiber degradation, making it less suitable for high-precision bioengineered silk production.

Cocoon Degumming Pre-Reeling

Cocoon degumming pre-reeling involves removing sericin, the gummy protein binding silk fibers, to enhance filament smoothness and luster essential for high-quality silk reeling. Silk gland extraction bypasses this degumming step as it directly harvests fibroin-rich silk proteins from silkworm glands, offering a raw silk source with different properties compared to traditionally reeled silk.

Wet Silk Gland Extraction Process

Wet silk gland extraction in sericulture involves carefully dissecting live silkworms to harvest intact silk glands, preserving fibroin and sericin proteins crucial for quality silk production, contrasting with silk reeling which unwinds fibers from boiled cocoons. This method enhances silk protein yield and purity, enabling advanced biomedical applications and producing finer high-grade silk fibers compared to traditional reeling techniques.

In-situ Silk Protein Recovery

Silk gland extraction enables in-situ silk protein recovery by directly isolating fibroin and sericin from live silkworm glands, preserving protein integrity and functionality more effectively than traditional silk reeling. Compared to silk reeling, which unwinds silk fibers from cocoons and often leads to protein degradation, gland extraction provides higher-quality silk proteins crucial for biomedical and textile applications.

Non-invasive Cocoon Bioprocessing

Silk gland extraction preserves the integrity of the cocoon by isolating the glands directly, allowing for the production of high-purity fibroin and sericin proteins without damaging the cocoon structure. Silk reeling, a non-invasive cocoon bioprocessing method, facilitates continuous filament extraction by carefully unwinding the intact cocoon, maximizing silk filament length and quality for textile applications.

Precision Silk Reeling Robotics

Precision silk reeling robotics significantly enhance efficiency and consistency in cocoon processing by automating the delicate extraction of continuous silk fibers, reducing human error inherent in manual silk gland extraction. These advanced systems optimize silk yield and quality by precisely controlling tension and speed during reeling, outperforming traditional silk gland extraction methods that often damage fibers and lower overall silk integrity.

Silk Gland Extraction vs Silk Reeling for Cocoon Processing Infographic

agridif.com

agridif.com