Wet cocoon stifling involves immersing cocoons in hot water or steam to kill the pupae, preserving silk quality with reduced fiber damage. Dry cocoon stifling uses high-temperature air or direct heat, which can be faster but risks weakening silk fibers and lowering reeling efficiency. Choosing between wet and dry methods depends on balancing cocoon processing speed with the desired silk quality and durability.

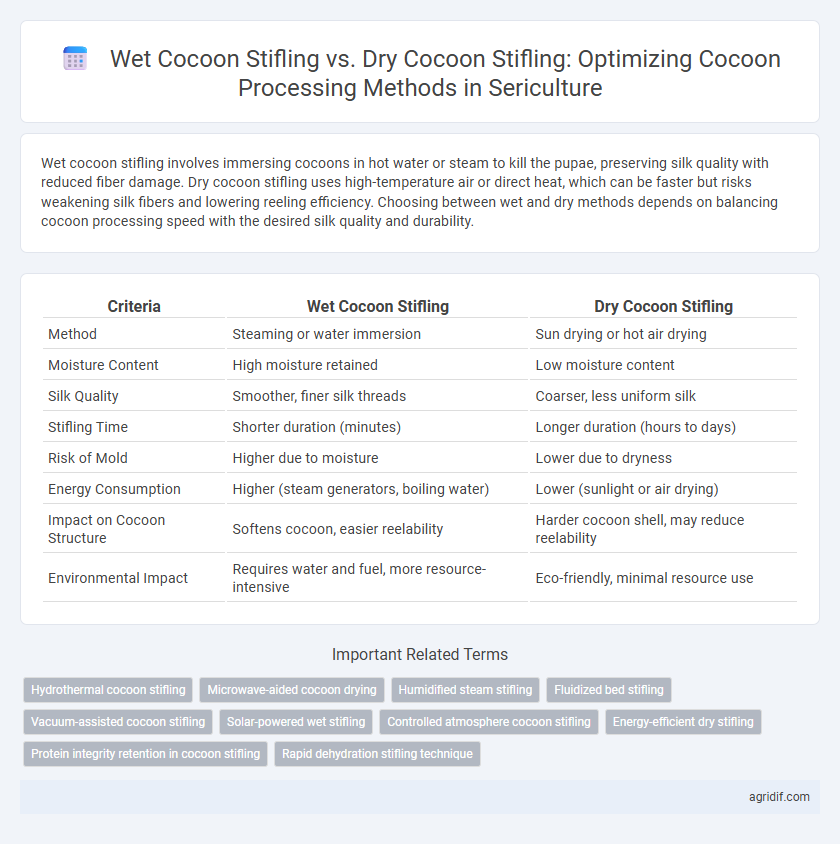

Table of Comparison

| Criteria | Wet Cocoon Stifling | Dry Cocoon Stifling |

|---|---|---|

| Method | Steaming or water immersion | Sun drying or hot air drying |

| Moisture Content | High moisture retained | Low moisture content |

| Silk Quality | Smoother, finer silk threads | Coarser, less uniform silk |

| Stifling Time | Shorter duration (minutes) | Longer duration (hours to days) |

| Risk of Mold | Higher due to moisture | Lower due to dryness |

| Energy Consumption | Higher (steam generators, boiling water) | Lower (sunlight or air drying) |

| Impact on Cocoon Structure | Softens cocoon, easier reelability | Harder cocoon shell, may reduce reelability |

| Environmental Impact | Requires water and fuel, more resource-intensive | Eco-friendly, minimal resource use |

Overview of Cocoon Stifling in Sericulture

Wet cocoon stifling involves immersing freshly harvested cocoons in hot water or steam to kill the pupae, preserving silk quality by preventing microbial growth and maintaining moisture content. Dry cocoon stifling uses heated air to kill the pupae, which can lead to faster processing but may cause higher moisture loss and affect silk fiber strength. Both methods are critical in sericulture for ensuring effective pupal death while influencing silk yield, texture, and dyeing properties.

Understanding Wet Cocoon Stifling: Process and Techniques

Wet cocoon stifling involves exposing freshly harvested cocoons to steam or hot water vapor to kill the pupa inside without damaging the silk fibers, enhancing silk reelability and quality. This method efficiently prevents microbial growth and preserves filament length by maintaining moisture, crucial for high-grade silk production. Precise control of temperature and exposure duration during wet stifling optimizes cocoon conditioning, directly affecting the fineness and tensile strength of the resulting silk threads.

Dry Cocoon Stifling: Steps and Methods

Dry cocoon stifling involves applying controlled heat or sunlight to kill the pupae inside the cocoons without using moisture, preserving the silk's natural luster and quality. Common methods include hot air stifling in a chamber at temperatures around 45-50degC for several hours, or sun drying for consistent periods under monitored conditions to prevent over-drying or damage. This technique reduces the risk of cocoon spoilage and enhances filament reelability, improving overall silk yield and quality in sericulture processing.

Comparative Analysis: Wet vs Dry Cocoon Stifling

Wet cocoon stifling involves immersing cocoons in hot water or steam, which efficiently kills pupae while preserving the silk fibers' luster and tensile strength. Dry cocoon stifling uses heated air or sunlight, which offers better moisture control but may lead to increased fiber brittleness and lower reelability. Comparative analysis indicates wet stifling enhances silk quality and reeling efficiency, whereas dry stifling is more energy-efficient and suited for regions with abundant sunlight.

Impact on Silk Quality: Wet vs Dry Stifling

Wet cocoon stifling preserves the natural moisture content, resulting in silk fibers with higher tensile strength and improved luster compared to dry stifling. Dry cocoon stifling, involving exposure to high temperatures, often causes fiber brittleness and reduced elongation properties, negatively impacting the overall silk quality. Maintaining optimal humidity and temperature during wet stifling minimizes fibroin degradation, thereby enhancing the final silk's texture and dye uptake.

Energy and Resource Requirements in Both Methods

Wet cocoon stifling requires substantial amounts of water and energy to maintain optimal humidity and temperature conditions, making it more resource-intensive compared to dry stifling. Dry cocoon stifling relies primarily on controlled heat sources, significantly reducing water usage and allowing for more energy-efficient operation with better resource sustainability. The choice between these methods impacts overall production costs and environmental footprint, with dry stifling emerging as the preferable option for energy conservation and resource management in modern sericulture.

Effects on Cocoon Storage and Shelf Life

Wet cocoon stifling involves using moisture and heat to kill pupae, which helps maintain cocoon softness and reduces brittleness, extending the cocoon's shelf life during storage by preventing premature hardening. Dry cocoon stifling uses dry heat, causing rapid moisture loss that can lead to cocoon brittleness and decreased elasticity, negatively affecting storage quality and shortening shelf life. Proper selection between wet and dry stifling methods significantly impacts the preservation of cocoon quality and longevity in sericulture.

Environmental Considerations of Stifling Methods

Wet cocoon stifling, involving steaming or boiling, consumes significant water and generates wastewater requiring proper disposal to avoid environmental pollution, whereas dry cocoon stifling, typically using hot air or solar heat, minimizes water usage and reduces effluent production. Dry methods lead to lower greenhouse gas emissions due to reduced energy consumption when solar or ambient heat sources are employed. Choice of stifling method directly influences resource efficiency and ecological footprint in sericulture processing.

Cost Implications for Farmers and Producers

Wet cocoon stifling requires higher water usage and labor costs, increasing overall expenses for farmers, whereas dry cocoon stifling consumes less water but demands energy for heat generation, impacting producers' operational costs. Farmers using wet stifling face potential losses due to longer process times and higher spoilage rates, while dry stifling offers efficiency but requires investment in heat stifling equipment. Cost implications vary based on regional resource availability, with dry stifling often preferred in energy-accessible areas and wet stifling in water-abundant, low-energy regions.

Recommendations for Optimal Cocoon Processing

Wet cocoon stifling preserves moisture content, leading to softer silk fibers ideal for high-quality fabric production, while dry cocoon stifling reduces moisture more effectively, enhancing silk reelability and storage stability. For optimal cocoon processing, selecting wet stifling is recommended when fiber softness and luster are prioritized, whereas dry stifling suits large-scale industrial reelers aiming for efficient degumming and longer shelf life. Consistent temperature control between 65-70degC and humidity regulation during stifling directly impact cocoon quality, silk yield, and filament length.

Related Important Terms

Hydrothermal cocoon stifling

Hydrothermal cocoon stifling, a wet cocoon processing method, utilizes controlled steam or hot water to kill pupae while preserving filament quality and enhancing silk reeling efficiency. Compared to dry cocoon stifling, this technique reduces thread breakage and maintains protein structure, resulting in superior fiber strength and luster during sericulture production.

Microwave-aided cocoon drying

Microwave-aided cocoon drying offers precise moisture control and energy efficiency compared to traditional wet cocoon stifling, which relies on steam and often leads to uneven heat distribution and extended processing times. This advanced dry cocoon stifling technique enhances silk quality by preventing fiber degradation and reduces microbial contamination, ensuring a superior sericulture output.

Humidified steam stifling

Humidified steam stifling in wet cocoon processing maintains optimal humidity and temperature, preventing damage to silk fibers and enhancing reelability compared to dry cocoon stifling which risks overheating and fiber brittleness. This method improves cocoon disinfection, reduces moisture loss, and preserves filament strength critical for high-quality silk production.

Fluidized bed stifling

Wet cocoon stifling, involving steaming or hot water, preserves cocoon moisture but increases drying time and energy consumption compared to dry cocoon stifling methods like fluidized bed stifling. Fluidized bed stifling offers uniform heat distribution and rapid drying by suspending cocoons in heated air, significantly enhancing processing efficiency and cocoon quality in sericulture.

Vacuum-assisted cocoon stifling

Vacuum-assisted cocoon stifling enhances dry cocoon stifling by efficiently removing moisture through controlled low-pressure conditions, resulting in improved filament quality and reduced damage compared to traditional wet cocoon stifling methods. This advanced technique preserves the natural luster and tensile strength of silk fibers, optimizing cocoon processing for high-grade silk production.

Solar-powered wet stifling

Solar-powered wet stifling utilizes controlled solar heat and moisture to efficiently kill pupae inside cocoons, preserving silk quality and reducing environmental impact compared to traditional dry stifling methods that employ direct heat and risk damaging fibers. This sustainable approach enhances fiber elasticity and reelability by maintaining optimal cocoon moisture levels during stifling, contributing to higher-quality silk production in sericulture.

Controlled atmosphere cocoon stifling

Controlled atmosphere cocoon stifling utilizes precise regulation of temperature, humidity, and gas composition to effectively kill pupae while preserving cocoon quality, outperforming traditional wet and dry stifling methods by minimizing cocoon damage and optimizing silk filament length. This advanced technique enhances sericulture production by reducing microbial growth and preventing discoloration, thereby improving the overall efficiency and quality of silk processing.

Energy-efficient dry stifling

Dry cocoon stifling in sericulture offers a more energy-efficient alternative to traditional wet stifling by reducing water usage and minimizing drying time, directly lowering operational costs. This method enhances cocoon quality by preserving silk fibroin integrity and reducing microbial growth, leading to improved silk yield and fiber strength in cocoon processing.

Protein integrity retention in cocoon stifling

Wet cocoon stifling preserves protein integrity more effectively by promptly halting enzymatic activity and microbial degradation through controlled moisture and temperature conditions. Dry cocoon stifling, while easier to manage, risks protein denaturation due to uneven heat distribution and prolonged exposure, resulting in reduced silk quality and tensile strength.

Rapid dehydration stifling technique

Rapid dehydration stifling in sericulture accelerates moisture removal from wet cocoons, preserving silk quality and preventing microbial growth more effectively than traditional dry cocoon stifling. This method reduces processing time and enhances silk filament strength by minimizing heat damage and ensuring uniform dehydration.

Wet cocoon stifling vs Dry cocoon stifling for cocoon processing Infographic

agridif.com

agridif.com