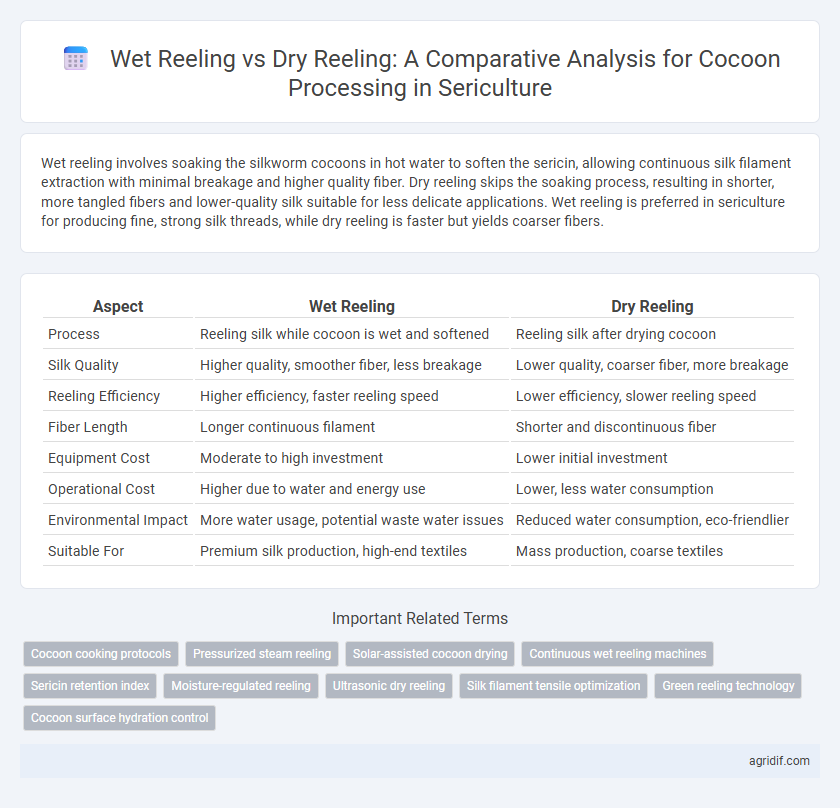

Wet reeling involves soaking the silkworm cocoons in hot water to soften the sericin, allowing continuous silk filament extraction with minimal breakage and higher quality fiber. Dry reeling skips the soaking process, resulting in shorter, more tangled fibers and lower-quality silk suitable for less delicate applications. Wet reeling is preferred in sericulture for producing fine, strong silk threads, while dry reeling is faster but yields coarser fibers.

Table of Comparison

| Aspect | Wet Reeling | Dry Reeling |

|---|---|---|

| Process | Reeling silk while cocoon is wet and softened | Reeling silk after drying cocoon |

| Silk Quality | Higher quality, smoother fiber, less breakage | Lower quality, coarser fiber, more breakage |

| Reeling Efficiency | Higher efficiency, faster reeling speed | Lower efficiency, slower reeling speed |

| Fiber Length | Longer continuous filament | Shorter and discontinuous fiber |

| Equipment Cost | Moderate to high investment | Lower initial investment |

| Operational Cost | Higher due to water and energy use | Lower, less water consumption |

| Environmental Impact | More water usage, potential waste water issues | Reduced water consumption, eco-friendlier |

| Suitable For | Premium silk production, high-end textiles | Mass production, coarse textiles |

Introduction to Cocoon Reeling in Sericulture

Wet reeling and dry reeling are two essential methods for extracting silk fibers from cocoons in sericulture, each significantly impacting the quality and texture of the silk produced. Wet reeling involves soaking the cocoon in hot water to soften the sericin, facilitating smoother filament unwinding and yielding finer, more lustrous silk strands. Dry reeling allows the cocoon to dry partially or completely before reeling, resulting in coarser fibers suitable for robust silk products but often compromising thread uniformity and tensile strength.

Overview of Wet Reeling and Dry Reeling Methods

Wet reeling involves extracting silk fibers from soaked cocoons, resulting in smoother, stronger filaments ideal for high-quality silk production. Dry reeling processes cocoons without soaking, preserving natural sericin gum, leading to coarser yarns suitable for coarse silk varieties. Each method impacts fiber length, texture, and yarn strength, influencing the final silk quality in sericulture.

Key Differences Between Wet and Dry Reeling

Wet reeling involves soaking cocoons in hot water to soften sericin, enabling easier unwinding of silk filaments, resulting in finer and stronger threads. Dry reeling extracts silk without boiling, preserving natural sericin and producing coarser, less uniform fibers. Key differences include fiber quality, processing time, and suitability for different silk products, with wet reeling favored for high-grade silk and dry reeling for specialized or traditional textiles.

Equipment Used in Wet and Dry Reeling Processes

Wet reeling equipment typically includes soaking tanks, reeling wheels, and water baths designed to soften silk cocoons by immersing them in hot water, facilitating smooth filament extraction. Dry reeling machinery involves heating drums or heated rollers that gently dry the cocoons, allowing filament unwinding without soaking, thus preserving certain silk qualities. Both systems require precise temperature control mechanisms and tension regulators to ensure optimal filament quality and reeling efficiency.

Step-by-Step Process of Wet Reeling

Wet reeling involves immersing cocoons in hot water to soften sericin, followed by careful unwinding of silk filaments onto reeling frames to produce continuous threads. The step-by-step process begins with sorting cocoons, boiling them for precise durations to loosen fibers without damaging them, then reeling the silk directly in water to maintain filament integrity and strength. This method ensures higher filament quality and tensile strength compared to dry reeling, which reels silk from dried cocoons but often results in shorter, weaker fibers.

Step-by-Step Process of Dry Reeling

Dry reeling involves softening silk cocoons by heating them in a dry environment, typically using hot air or steam, to loosen sericin without immersing in water. Next, the softened cocoon fibers are carefully unwound using a dry reeling machine, minimizing fiber damage and preserving filament length. This method results in higher-quality silk suitable for fine textiles, with less water usage and reduced environmental impact compared to traditional wet reeling.

Quality and Yield Comparison: Wet Reeling vs Dry Reeling

Wet reeling maintains moisture in silk fibers during cocoon processing, resulting in higher filament strength, improved luster, and superior fabric quality compared to dry reeling. Yield from wet reeling is generally more consistent due to less fiber breakage, whereas dry reeling, which involves drying cocoons before extraction, often leads to weaker fibers and reduced overall yield. The choice between wet and dry reeling significantly impacts silk quality, filament length, and processing efficiency in sericulture production.

Economic Aspects of Wet and Dry Reeling Techniques

Wet reeling offers higher silk filament quality and yield, translating into greater market value but incurs increased water and labor costs, impacting overall profitability. Dry reeling reduces water usage and operational expenses, making it economically advantageous in regions facing water scarcity, though it produces slightly lower-quality silk. The choice between wet and dry reeling hinges on balancing initial investment, operational costs, and targeted silk quality to optimize economic returns in sericulture.

Environmental Impact of Wet and Dry Cocoon Processing

Wet reeling of silk cocoons involves immersing cocoons in hot water, leading to higher water consumption and potential wastewater contamination, impacting aquatic ecosystems. Dry reeling minimizes water use and reduces effluent discharge, making it a more environmentally sustainable choice. However, energy consumption during dry reeling may increase carbon emissions, requiring balanced evaluation of overall environmental footprint.

Choosing the Appropriate Reeling Method for Sericulturists

Wet reeling involves immersing cocoons in hot water to soften sericin, resulting in smoother and stronger silk fibers preferred for high-quality silk production. Dry reeling, which keeps cocoons dry during the process, yields coarser fibers that are easier to handle but less uniform in texture, suitable for lower-grade silk products. Sericulturists must choose the reeling method based on the desired silk quality, fiber strength, and end-use requirements to optimize yield and market value.

Related Important Terms

Cocoon cooking protocols

Wet reeling cocoon cooking protocols involve soaking cocoons in hot water at approximately 70-80degC to soften sericin, facilitating smooth filament extraction with minimal breakage. In contrast, dry reeling employs controlled dry heat or steamed conditions to cook cocoons, preserving filament quality but requiring precise temperature regulation to prevent fiber damage.

Pressurized steam reeling

Pressurized steam reeling in wet reeling method enhances cocoon softening by penetrating sericin more effectively, resulting in smoother and stronger silk fibers with higher filament length compared to dry reeling. This technique reduces cocoon damage and improves silk quality by maintaining optimal moisture and temperature during the reeling process, increasing overall yield and efficiency in sericulture.

Solar-assisted cocoon drying

Wet reeling preserves silk filament strength and quality by processing freshly harvested cocoons, whereas dry reeling involves drying cocoons before unwinding, which can reduce filament uniformity. Solar-assisted cocoon drying enhances the dry reeling process by using sustainable solar energy to efficiently reduce moisture content, improving cocoon preservation and minimizing environmental impact.

Continuous wet reeling machines

Continuous wet reeling machines enhance sericulture efficiency by extracting silk directly from fresh cocoons immersed in hot water, preserving fiber strength and luster compared to dry reeling methods, which process partially dried cocoons and often result in lower-quality silk. This technology enables higher throughput and uniform yarn quality, making it a preferred choice for commercial silk production.

Sericin retention index

Wet reeling preserves a higher sericin retention index compared to dry reeling, maintaining the protective sericin layer that enhances silk fiber strength and flexibility. The elevated sericin content in wet reeling contributes to improved silk quality and reduces fiber breakage during processing.

Moisture-regulated reeling

Wet reeling maintains higher moisture content in cocoons, enhancing filament flexibility and reducing breakage, while dry reeling processes cocoons with lower moisture, resulting in coarser silk threads but faster reeling rates. Moisture-regulated reeling balances hydration levels to optimize filament strength, reelability, and silk quality, crucial for high-grade raw silk production.

Ultrasonic dry reeling

Ultrasonic dry reeling enhances cocoon processing by using high-frequency sound waves to soften sericin, enabling smooth filament extraction without water, which preserves fiber quality and reduces environmental impact compared to traditional wet reeling. This technology increases yield efficiency, maintains tensile strength, and minimizes cost by eliminating drying steps and water consumption inherent to wet reeling methods.

Silk filament tensile optimization

Wet reeling preserves the silk fibroin's natural moisture, resulting in higher filament tensile strength and elasticity, which optimizes the silk's durability during processing. Dry reeling, while faster, often leads to reduced tensile strength and increased brittleness due to moisture loss, negatively impacting filament quality and overall silk filament performance.

Green reeling technology

Wet reeling preserves silk filament integrity and enhances fiber strength by reeling cocoons immediately after softening, while dry reeling involves extracting fibers from dried cocoons, often resulting in lower filament quality. Green reeling technology combines the advantages of wet reeling with eco-friendly practices, using minimal water and energy to optimize cocoon processing and improve sustainable silk production.

Cocoon surface hydration control

Wet reeling maintains optimal cocoon surface hydration by submerging cocoons in water, preserving fibroin filament integrity and enhancing silk uniformity. Dry reeling reduces moisture exposure, minimizing risks of filament breakage during processing but requires precise humidity control to prevent cocoons from becoming brittle.

Wet reeling vs Dry reeling for cocoon processing Infographic

agridif.com

agridif.com