Disinfectant fumigation offers a more uniform and thorough approach to controlling silkworm diseases by penetrating hard-to-reach areas and eliminating pathogens in the environment. Chemical sprays provide targeted treatment on silkworms and their feed but may pose risks of chemical residues affecting larval health and silk quality. Choosing between fumigation and chemical sprays depends on the severity of infection, environmental conditions, and the need to balance effective disease control with silkworm safety.

Table of Comparison

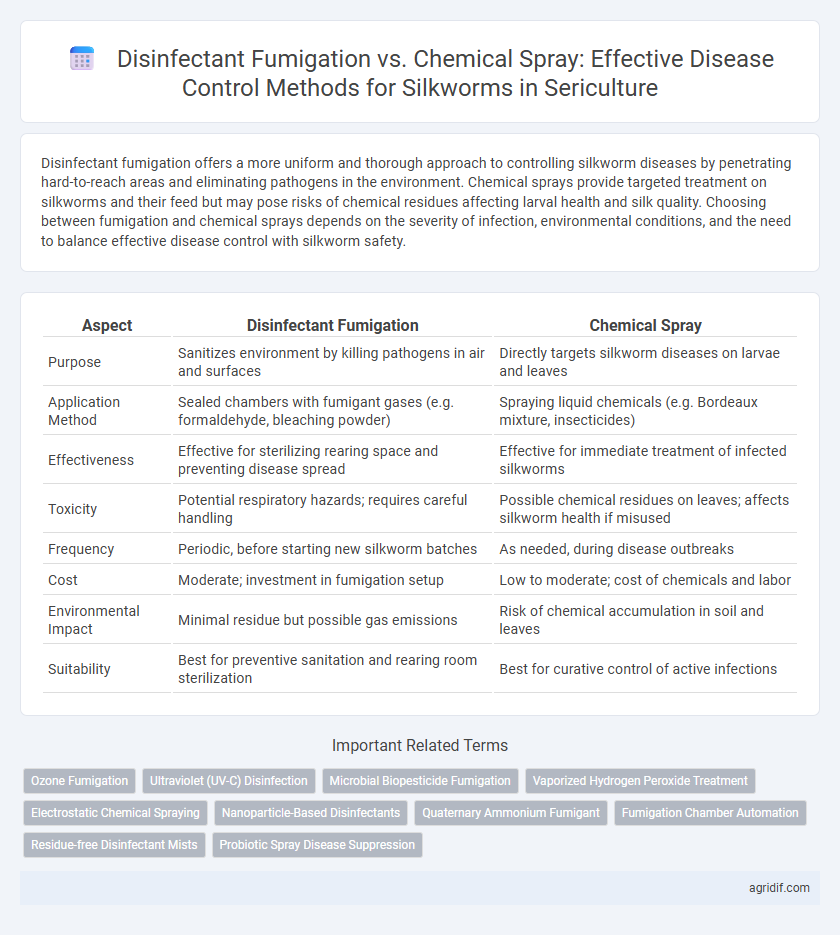

| Aspect | Disinfectant Fumigation | Chemical Spray |

|---|---|---|

| Purpose | Sanitizes environment by killing pathogens in air and surfaces | Directly targets silkworm diseases on larvae and leaves |

| Application Method | Sealed chambers with fumigant gases (e.g. formaldehyde, bleaching powder) | Spraying liquid chemicals (e.g. Bordeaux mixture, insecticides) |

| Effectiveness | Effective for sterilizing rearing space and preventing disease spread | Effective for immediate treatment of infected silkworms |

| Toxicity | Potential respiratory hazards; requires careful handling | Possible chemical residues on leaves; affects silkworm health if misused |

| Frequency | Periodic, before starting new silkworm batches | As needed, during disease outbreaks |

| Cost | Moderate; investment in fumigation setup | Low to moderate; cost of chemicals and labor |

| Environmental Impact | Minimal residue but possible gas emissions | Risk of chemical accumulation in soil and leaves |

| Suitability | Best for preventive sanitation and rearing room sterilization | Best for curative control of active infections |

Importance of Disease Control in Sericulture

Effective disease control in sericulture is critical to maintaining healthy silkworm populations and optimizing silk yield. Disinfectant fumigation penetrates silkworm rearing environments to eliminate pathogens, reducing infection rates more uniformly than chemical sprays, which primarily target surface contamination. Employing disease control methods like fumigation and chemical sprays minimizes economic losses and supports sustainable silk production by preventing outbreaks of bacterial, viral, and fungal diseases.

Overview of Disinfectant Fumigation

Disinfectant fumigation in sericulture involves using gaseous disinfectants to penetrate silkworm rearing environments, effectively eliminating pathogens like bacteria, viruses, and fungi. This method ensures thorough sterilization of rearing trays, storage areas, and mulberry leaves, reducing disease incidence caused by pathogens such as Bacillus thuringiensis and nuclear polyhedrosis virus. Compared to chemical sprays, fumigation provides a deeper reach, minimizing residual toxicity and promoting healthier silkworm development.

Chemical Spray Methods Explained

Chemical spray methods for silkworm disease control involve the targeted application of insecticides and fungicides to eliminate pathogens and pests affecting silkworm crops. These sprays penetrate the larval environment, providing rapid action against bacterial, viral, and fungal infections while minimizing damage to the silkworms themselves. Proper selection and concentration of chemicals ensure effective disease management with reduced resistance buildup compared to traditional fumigation techniques.

Comparative Efficacy Against Silkworm Pathogens

Disinfectant fumigation demonstrates superior efficacy against silkworm pathogens by penetrating cocoon layers and reaching hidden infectious agents, unlike chemical sprays that primarily affect surface-level contaminants. Studies reveal fumigation significantly reduces fungal spores and bacterial loads within rearing houses, leading to lower disease incidence rates in silkworm populations. Chemical sprays, while effective for immediate surface disinfection, often require repeated applications and may contribute to pathogen resistance, making fumigation a more reliable method for long-term sericulture disease management.

Impact on Silkworm Health and Productivity

Disinfectant fumigation effectively controls pathogens without directly contacting silkworms, minimizing stress and preserving larval vitality. Chemical sprays, while potent against pests, risk toxicity and cause behavioral changes that reduce feeding and cocoon quality. Optimizing disease control methods enhances silkworm health and maximizes silk yield by maintaining optimal growth conditions and preventing disease outbreaks.

Safety Considerations for Handlers

Disinfectant fumigation offers enhanced safety for handlers by reducing direct contact with toxic substances compared to chemical sprays, which often contain harmful residues that can cause skin irritation or respiratory issues. Proper fumigation protocols minimize exposure risks through controlled application and ventilation, ensuring safer working conditions in sericulture environments. In contrast, chemical sprays require protective gear and strict handling guidelines to prevent adverse health effects during disease control in silkworm rearing.

Environmental Effects and Residue Concerns

Disinfectant fumigation for silkworm disease control typically produces fewer chemical residues, reducing the risk of contamination in mulberry leaves and soil compared to chemical sprays. Chemical sprays often introduce persistent toxic compounds that can accumulate in the ecosystem, harming beneficial microorganisms and pollinators essential for sericulture sustainability. Employing fumigation minimizes environmental impact by targeting pathogens more selectively while reducing chemical runoff and residue in silkworm rearing environments.

Cost-Effectiveness Analysis

Disinfectant fumigation offers a cost-effective approach to silkworm disease control by reducing pathogen load with minimal labor and chemical input compared to chemical sprays. Chemical sprays involve higher expenses for repeated applications and pose risks of chemical resistance and environmental contamination, increasing long-term costs. Cost-effectiveness analysis favors disinfectant fumigation for sustainable sericulture due to lower operational costs and enhanced silkworm health outcomes.

Adoption in Small-Scale vs. Commercial Farms

Disinfectant fumigation is widely adopted in small-scale sericulture due to its cost-effectiveness and ease of application, helping control silkworm diseases like pebrine and muscardine with minimal equipment. Commercial farms prefer chemical sprays for their targeted action and scalability, enabling precise dosage control and reduced labor in managing large silkworm populations. The choice between fumigation and chemical spray reflects the farm size, resource availability, and disease management efficiency required in sericulture operations.

Recommendations for Integrated Disease Management

Disinfectant fumigation effectively reduces pathogen load in silkworm rearing environments by targeting spores and bacteria in hard-to-reach areas, while chemical sprays offer rapid control of active infections on silkworms and mulberry leaves. Integrated Disease Management (IDM) recommends combining these methods to minimize chemical resistance and environmental impact, emphasizing timely fumigation during off-rearing periods and precise chemical application during disease outbreaks. Regular monitoring, optimal hygiene, and adherence to recommended dosages enhance silkworm health and sericulture productivity.

Related Important Terms

Ozone Fumigation

Ozone fumigation as a disinfectant method in sericulture offers a non-chemical, eco-friendly alternative to traditional chemical sprays, effectively eliminating pathogens such as bacteria, fungi, and viruses responsible for silkworm diseases. Its strong oxidizing properties enable thorough sterilization of rearing environments without leaving harmful residues, enhancing silkworm health and cocoon quality while reducing the risk of chemical resistance.

Ultraviolet (UV-C) Disinfection

Ultraviolet (UV-C) disinfection offers a non-chemical method for controlling silkworm diseases by effectively inactivating pathogens on mulberry leaves and rearing surfaces without harmful residues. Compared to traditional chemical sprays, UV-C fumigation reduces the risk of silkworm toxicity and environmental contamination while maintaining high efficacy against bacterial and viral infections in sericulture.

Microbial Biopesticide Fumigation

Microbial biopesticide fumigation offers targeted disease control in sericulture by effectively reducing pathogenic microorganisms on silkworm rearing surfaces without harming beneficial microbes, unlike broad-spectrum chemical sprays, which may cause resistance and environmental toxicity. This eco-friendly approach enhances silkworm health and cocoon yield by maintaining microbial balance and minimizing chemical residues in silk production.

Vaporized Hydrogen Peroxide Treatment

Vaporized Hydrogen Peroxide Treatment offers a highly effective, eco-friendly alternative to chemical sprays for silkworm disease control by eliminating pathogens without harmful residues. This disinfectant fumigation method penetrates silkworm rearing houses thoroughly, reducing microbial load and maintaining a safer environment for larval development compared to traditional chemical applications.

Electrostatic Chemical Spraying

Electrostatic chemical spraying enhances the effectiveness of silkworm disease control by ensuring uniform disinfectant coverage on larvae and rearing trays, reducing chemical usage and environmental impact compared to traditional chemical sprays. This method improves pest and pathogen elimination by promoting better adhesion and penetration of the disinfectants, thereby increasing the overall health and productivity of sericulture operations.

Nanoparticle-Based Disinfectants

Nanoparticle-based disinfectants provide eco-friendly and efficient fumigation methods for controlling silkworm diseases, offering superior penetration and prolonged antimicrobial activity compared to traditional chemical sprays. These nanomaterials reduce toxicity risks and environmental impact while enhancing silkworm health and cocoon yield in sericulture.

Quaternary Ammonium Fumigant

Quaternary Ammonium Fumigant offers a targeted and efficient method for silkworm disease control by penetrating cocoon layers and disinfecting rearing environments more effectively than surface-level chemical sprays. Its prolonged residual activity and lower toxicity to silkworms make it a preferable alternative over conventional chemical sprays, reducing the risk of pathogen resistance and environmental contamination.

Fumigation Chamber Automation

Disinfectant fumigation in sericulture offers uniform pathogen eradication within controlled fumigation chambers, ensuring consistent silkworm disease management with reduced chemical residues. Automated fumigation chambers enhance precision, optimize disinfectant dosage, and provide real-time monitoring, significantly improving silkworm health and increasing cocoon yield compared to traditional chemical sprays.

Residue-free Disinfectant Mists

Disinfectant fumigation generates fine, residue-free mists that effectively eliminate silkworm pathogens without contaminating mulberry leaves, ensuring safe sericulture practices and higher cocoon quality. Chemical sprays, on the other hand, often leave harmful residues that can accumulate on foliage, posing risks to silkworm health and silk purity.

Probiotic Spray Disease Suppression

Probiotic spray promotes beneficial microbial growth that suppresses silkworm pathogens more effectively than traditional chemical sprays, reducing reliance on harmful chemicals and enhancing larval immunity. Disinfectant fumigation eliminates surface pathogens but may disrupt microflora balance, whereas probiotic treatments maintain ecological stability critical for sustainable sericulture.

Disinfectant fumigation vs Chemical spray for silkworm disease control Infographic

agridif.com

agridif.com