Disinfectants provide an effective chemical barrier against pathogens in sericulture pet environments, targeting bacteria and fungi on surfaces to reduce disease spread. Heat sterilization offers a reliable physical method by using high temperatures to eliminate microbial contaminants on equipment and rearing containers without chemical residues. Combining both approaches enhances overall disease management by ensuring thorough pathogen control in silkworm habitats.

Table of Comparison

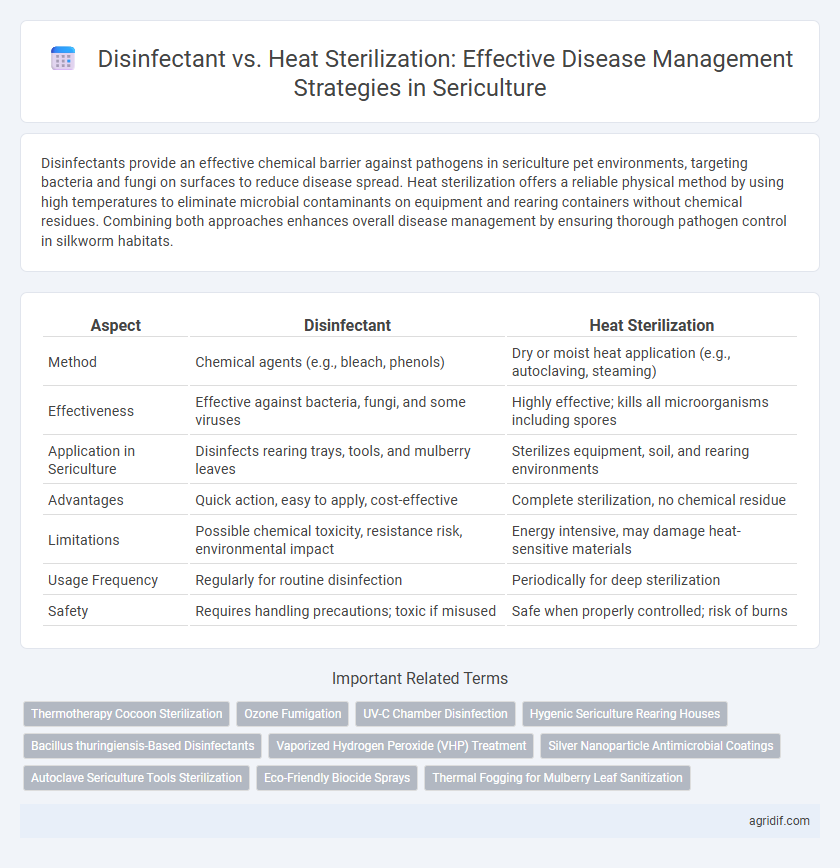

| Aspect | Disinfectant | Heat Sterilization |

|---|---|---|

| Method | Chemical agents (e.g., bleach, phenols) | Dry or moist heat application (e.g., autoclaving, steaming) |

| Effectiveness | Effective against bacteria, fungi, and some viruses | Highly effective; kills all microorganisms including spores |

| Application in Sericulture | Disinfects rearing trays, tools, and mulberry leaves | Sterilizes equipment, soil, and rearing environments |

| Advantages | Quick action, easy to apply, cost-effective | Complete sterilization, no chemical residue |

| Limitations | Possible chemical toxicity, resistance risk, environmental impact | Energy intensive, may damage heat-sensitive materials |

| Usage Frequency | Regularly for routine disinfection | Periodically for deep sterilization |

| Safety | Requires handling precautions; toxic if misused | Safe when properly controlled; risk of burns |

Overview of Disease Management in Sericulture

Disinfectant and heat sterilization are critical methods in sericulture disease management, targeting the elimination of pathogens such as bacteria, fungi, and viruses affecting silkworms. Disinfectants like formalin and bleaching powder are widely used to sanitize rearing trays and equipment quickly and effectively, ensuring minimal pathogen presence. Heat sterilization, involving exposure to high temperatures (typically 80-90degC), offers a chemical-free approach to sterilize mulberry leaves and rearing tools, reducing the risk of chemical residue and improving overall silkworm health.

Role of Disinfection in Sericulture Practices

Disinfection plays a crucial role in sericulture by eliminating pathogens from rearing trays, equipment, and storage containers, thereby preventing the spread of diseases like muscardine and grasserie in silkworm populations. Chemical disinfectants such as formalin, chlorinated lime, and potassium permanganate are widely used due to their effectiveness in targeting specific bacterial and fungal spores without damaging mulberry leaves or silkworm larvae. Proper disinfection protocols integrated with heat sterilization optimize disease management by reducing microbial load and ensuring a cleaner environment for healthy sericulture development.

Heat Sterilization: Principles and Methods

Heat sterilization in sericulture involves using high temperatures to eliminate pathogens from rearing trays, tools, and equipment, ensuring a disease-free environment for silkworms. Common methods include boiling, steaming, and solarization, which effectively destroy fungal spores, bacteria, and viruses without chemical residues. This approach enhances silkworm health and productivity by preventing infections such as grasserie and pebrine, crucial for sustainable silk production.

Types of Disinfectants Used in Sericulture

Disinfectants commonly used in sericulture include phenolic compounds, quaternary ammonium compounds, and chlorine-based agents, which effectively target pathogens affecting silkworm health. Phenolic disinfectants disrupt cell membranes of harmful bacteria and fungi, while quaternary ammonium compounds offer broad-spectrum antimicrobial activity with minimal toxicity to silkworms. Chlorine-based disinfectants, such as sodium hypochlorite, provide rapid and efficient sterilization of rearing trays and tools, reducing disease outbreaks in sericulture farms.

Comparative Efficacy: Disinfectants vs Heat Sterilization

Disinfectants provide targeted microbial control by chemically eliminating pathogens on surfaces and equipment used in sericulture, offering rapid action against bacteria, fungi, and viruses. Heat sterilization employs high temperatures to denature microbial proteins and enzymes, achieving comprehensive eradication of pathogens in silkworm rearing environments and raw materials. While disinfectants allow localized and immediate application, heat sterilization ensures deeper penetration and longer-lasting disease management by destroying resistant spores and thermotolerant organisms.

Impact on Silkworm Health and Cocoon Yield

Disinfectants effectively reduce microbial load on rearing surfaces, minimizing disease outbreaks without directly impacting silkworm physiology, thereby maintaining cocoon quality and yield. Heat sterilization, while potent in eradicating pathogens, may create an unfavorable microenvironment by altering humidity and thermal conditions, potentially stressing silkworms and reducing survival rates and cocoon productivity. Optimal disease management strategies integrate chemical disinfection with controlled heat treatments to balance pathogen control and silkworm health, maximizing cocoon yield in sericulture.

Environmental and Economic Considerations

Disinfectants in sericulture provide targeted pathogen control with lower initial costs but pose environmental risks due to chemical residues and potential toxicity to beneficial organisms. Heat sterilization offers an eco-friendly alternative by eliminating pathogens without chemical pollutants, promoting sustainable cocoon production, though it involves higher energy consumption and equipment investment. Balancing these methods requires assessing long-term environmental impact against economic feasibility to ensure effective, sustainable disease management.

Application Techniques and Operational Safety

Disinfectant application in sericulture involves precise spraying or dipping methods to ensure thorough microbial control on mulberry plants and silkworm eggs, while maintaining operator safety through the use of protective gear and ventilation. Heat sterilization employs controlled hot air or steam treatments to eliminate pathogens without chemical residues, requiring careful temperature monitoring and equipment maintenance to avoid damage to silkworm eggs. Both techniques demand strict adherence to operational protocols to maximize effectiveness and minimize health risks to workers and the sericulture ecosystem.

Limitations and Risks of Each Method

Disinfectant use in sericulture poses risks of chemical residues affecting silkworm health and cocoon quality, with limitations including incomplete pathogen elimination and potential environmental contamination. Heat sterilization presents challenges such as uneven temperature distribution that may fail to eradicate all pathogens, alongside risks of damaging mulberry leaves or silkworm eggs due to excessive heat exposure. Both methods require careful management to balance effective disease control with minimizing adverse effects on sericulture productivity and sustainability.

Best Practices for Integrated Disease Management

Disinfectant application in sericulture effectively reduces surface pathogens on mulberry leaves and rearing equipment, minimizing silkworm infection risks. Heat sterilization, involving the use of controlled hot air or steam, eradicates microbial contaminants without chemical residues, preserving sericulture product quality. Integrating both methods optimizes disease management by combining immediate pathogen control with sustainable environmental safety, enhancing overall silkworm health and silk yield.

Related Important Terms

Thermotherapy Cocoon Sterilization

Thermotherapy cocoon sterilization using controlled heat effectively eliminates pathogens in sericulture by denaturing proteins and inactivating spores without harmful chemical residues. This method offers superior disease management compared to disinfectants, providing eco-friendly, residue-free sterilization that maintains cocoon quality and prevents silkworm infections.

Ozone Fumigation

Ozone fumigation offers an effective alternative to heat sterilization and chemical disinfectants in sericulture by rapidly oxidizing pathogens without leaving harmful residues, enhancing cocoon quality and larval health. Its strong oxidizing properties target bacteria, fungi, and viruses in rearing environments, reducing disease incidence while maintaining mulberry leaf nutritional integrity.

UV-C Chamber Disinfection

UV-C chamber disinfection offers precise and chemical-free sterilization in sericulture, effectively targeting pathogens on silkworm eggs compared to traditional disinfectants that may leave residues or cause resistance. Heat sterilization, while useful, can damage delicate eggs and larvae, making UV-C treatment a preferred method for maintaining hygroscopic balance and ensuring disease-free silkworm cultivation.

Hygenic Sericulture Rearing Houses

Disinfectant use in hygienic sericulture rearing houses offers targeted pathogen control, effectively reducing microbial load without compromising silkworm health, whereas heat sterilization provides a broad-spectrum, chemical-free method that ensures complete eradication of contaminants on rearing equipment and surfaces. Integrating both methods enhances disease management by combining immediate microbial inactivation through heat with prolonged protection via chemical disinfectants, optimizing silkworm rearing conditions and increasing cocoon yield quality.

Bacillus thuringiensis-Based Disinfectants

Bacillus thuringiensis-based disinfectants offer targeted disease management in sericulture by effectively controlling microbial pathogens without harming silkworms, unlike heat sterilization which can degrade mulberry leaves and disrupt beneficial microbial flora. The bio-based mode of action of Bt formulations ensures sustainable pest control, minimizing chemical residues and promoting eco-friendly sericulture practices.

Vaporized Hydrogen Peroxide (VHP) Treatment

Vaporized Hydrogen Peroxide (VHP) treatment offers a highly effective disinfectant method in sericulture, capable of penetrating silkworm rearing environments to eliminate pathogens without residual toxicity. Unlike heat sterilization, VHP maintains the integrity of delicate equipment and mulberry leaves, ensuring optimal disease management and improved silkworm health.

Silver Nanoparticle Antimicrobial Coatings

Silver nanoparticle antimicrobial coatings exhibit superior efficacy compared to traditional disinfectants and heat sterilization in sericulture disease management by providing prolonged antimicrobial activity against pathogens affecting silkworms. These coatings disrupt microbial cell membranes and biofilms, reducing disease transmission in rearing environments while minimizing damage associated with heat treatments.

Autoclave Sericulture Tools Sterilization

Autoclave sterilization ensures effective eradication of pathogens from sericulture tools by applying high-pressure saturated steam at 121degC for 15-20 minutes, outperforming chemical disinfectants in eliminating bacterial and fungal spores. The precise temperature and pressure-controlled environment in autoclaves minimizes contamination risks during mulberry cultivation and silkworm rearing, enhancing disease management efficiency in sericulture production.

Eco-Friendly Biocide Sprays

Eco-friendly biocide sprays offer a sustainable alternative to chemical disinfectants in sericulture, effectively managing disease without harmful environmental impact. Compared to heat sterilization, these biocides provide targeted pathogen control, preserving beneficial microbes critical for mulberry leaf health and silkworm productivity.

Thermal Fogging for Mulberry Leaf Sanitization

Thermal fogging using heat sterilization effectively eliminates pathogens on mulberry leaves by generating fine disinfectant particles that penetrate leaf surfaces, enhancing disease management in sericulture. This method provides superior microbial control compared to traditional disinfectants, reducing the risk of silkworm diseases and promoting healthier cocoon production.

Disinfectant vs Heat sterilization for disease management Infographic

agridif.com

agridif.com