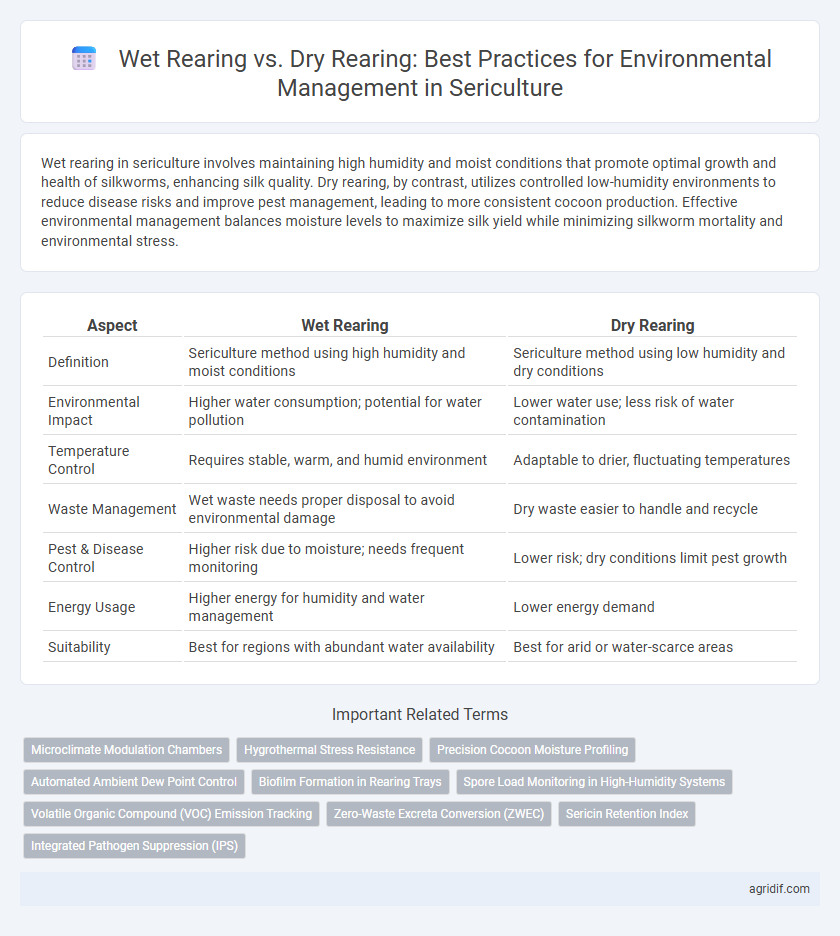

Wet rearing in sericulture involves maintaining high humidity and moist conditions that promote optimal growth and health of silkworms, enhancing silk quality. Dry rearing, by contrast, utilizes controlled low-humidity environments to reduce disease risks and improve pest management, leading to more consistent cocoon production. Effective environmental management balances moisture levels to maximize silk yield while minimizing silkworm mortality and environmental stress.

Table of Comparison

| Aspect | Wet Rearing | Dry Rearing |

|---|---|---|

| Definition | Sericulture method using high humidity and moist conditions | Sericulture method using low humidity and dry conditions |

| Environmental Impact | Higher water consumption; potential for water pollution | Lower water use; less risk of water contamination |

| Temperature Control | Requires stable, warm, and humid environment | Adaptable to drier, fluctuating temperatures |

| Waste Management | Wet waste needs proper disposal to avoid environmental damage | Dry waste easier to handle and recycle |

| Pest & Disease Control | Higher risk due to moisture; needs frequent monitoring | Lower risk; dry conditions limit pest growth |

| Energy Usage | Higher energy for humidity and water management | Lower energy demand |

| Suitability | Best for regions with abundant water availability | Best for arid or water-scarce areas |

Introduction to Sericulture and Rearing Methods

Sericulture involves cultivating silkworms to produce silk, with rearing methods significantly impacting environmental management. Wet rearing maintains high humidity and moisture levels, promoting silkworm growth but requiring careful water resource management to prevent contamination. Dry rearing conserves water and reduces waste, making it a sustainable option under water-scarce conditions while necessitating controlled temperature and feeding regimes to optimize silkworm health.

Defining Wet Rearing in Sericulture

Wet rearing in sericulture involves raising silkworms in high-humidity environments with frequent moisture application to maintain optimal conditions for larval development. This method enhances the mulberry leaf's freshness and prevents dehydration, directly impacting silk quality and yield. Effective environmental management under wet rearing reduces temperature fluctuations and controls microbial growth, ensuring healthier silkworms and improved cocoon production.

Understanding Dry Rearing Techniques

Dry rearing techniques in sericulture involve maintaining low humidity and minimizing water use to control environmental factors, reducing risks of fungal infections and disease in silkworms. This method optimizes temperature regulation and ventilation, creating a stable microclimate essential for healthy silkworm development. Implementing dry rearing promotes sustainable resource management and improves overall silkworm productivity.

Environmental Impact of Wet Rearing

Wet rearing in sericulture involves maintaining high humidity and frequent water applications to support silkworm growth, which can lead to increased water consumption and potential waterlogging issues in the cultivation area. This method may contribute to water resource depletion and the risk of microbial contamination due to stagnant moisture, impacting soil health and surrounding ecosystems. Effective environmental management requires balancing the benefits of wet rearing for silkworm vitality with practices that minimize water waste and ecological disruption.

Environmental Benefits of Dry Rearing

Dry rearing in sericulture significantly reduces water consumption, minimizing the strain on local water resources and promoting sustainable farming practices. The controlled moisture levels in dry rearing lower the risk of waterborne diseases, enhancing mulberry leaf quality and silkworm health. This method also decreases the likelihood of soil erosion and runoff, contributing to better land conservation and reduced environmental degradation.

Disease Management in Wet vs Dry Rearing Systems

Wet rearing systems in sericulture provide high humidity and temperature control that can promote silkworm growth but increase the risk of fungal and bacterial diseases due to moisture retention. Dry rearing systems reduce disease incidence by limiting excessive moisture, thus lowering fungal spore proliferation and insect pathogen transmission. Effective environmental management in dry rearing optimizes airflow and sanitation, minimizing pathogen development and enhancing silkworm health compared to wet rearing practices.

Resource Utilization: Water and Energy Efficiency

Wet rearing in sericulture requires higher water consumption to maintain optimal humidity and temperature for silkworm growth, influencing water resource management. Dry rearing utilizes less water but demands increased energy input for controlled environments, impacting overall energy efficiency. Balancing water and energy use is crucial for sustainable sericulture practices focused on environmental management.

Sustainability Considerations in Rearing Practices

Wet rearing in sericulture enhances mulberry leaf quality through controlled humidity, promoting healthier silkworm growth and reducing pesticide use, thereby supporting sustainability. Dry rearing conserves water resources and minimizes fungal disease incidence by maintaining lower moisture levels, which aligns with eco-friendly environmental management. Balancing these methods based on local climatic conditions optimizes resource efficiency and minimizes ecological impact in sustainable sericulture practices.

Climate Adaptability and Environmental Control

Wet rearing in sericulture offers superior climate adaptability by maintaining high humidity levels essential for silkworm growth, while dry rearing provides better environmental control through regulated temperature and reduced disease risks. Wet rearing is ideal for regions with naturally high moisture, promoting consistent larval development, whereas dry rearing suits areas with fluctuating or low humidity, allowing precise management of microclimatic conditions. Effective environmental management in sericulture hinges on balancing moisture control and temperature stability to optimize silkworm health and silk quality.

Conclusion: Optimal Rearing Choice for Eco-Friendly Sericulture

Wet rearing maintains higher humidity essential for silkworm health but risks water contamination if unmanaged, while dry rearing reduces water usage and potential pollution, enhancing sustainability. Optimal eco-friendly sericulture balances humidity control with resource conservation, often favoring dry rearing in water-scarce regions to minimize environmental impact. Implementing adaptive rearing techniques tailored to local climate and resource availability maximizes sericulture's ecological benefits.

Related Important Terms

Microclimate Modulation Chambers

Wet rearing in sericulture utilizes microclimate modulation chambers to maintain optimal humidity and temperature, enhancing silkworm health and cocoon quality by replicating natural environmental conditions. Dry rearing, conversely, employs controlled low-humidity chambers to inhibit fungal growth and reduce disease risk, supporting efficient silkworm development through precise microclimate regulation.

Hygrothermal Stress Resistance

Wet rearing in sericulture enhances hygrothermal stress resistance by maintaining optimal humidity and temperature levels that support robust silkworm development, reducing vulnerability to environmental fluctuations. Dry rearing exposes silkworms to variable conditions, increasing susceptibility to stress-induced mortality and affecting cocoon quality.

Precision Cocoon Moisture Profiling

Precision cocoon moisture profiling in sericulture distinguishes wet rearing, which maintains higher humidity levels ideal for optimal silk gland development, from dry rearing that promotes controlled dehydration to enhance silk fiber strength. Environmental management leverages these moisture profiles to optimize cocoon quality, balancing humidity with temperature to maximize silk yield and reduce disease incidence.

Automated Ambient Dew Point Control

Wet rearing in sericulture relies on maintaining high humidity through automated ambient dew point control, which enhances larval development and minimizes environmental stress by stabilizing microclimate conditions. In contrast, dry rearing uses controlled airflow and lower humidity settings, reducing fungal growth risks and optimizing energy efficiency in silkworm farming environments.

Biofilm Formation in Rearing Trays

Wet rearing in sericulture promotes biofilm formation on rearing trays due to constant moisture, enhancing microbial stability but increasing the risk of pathogenic growth, whereas dry rearing limits biofilm development by maintaining drier surfaces, reducing microbial load but potentially impacting larval health. Effective environmental management balances humidity to control biofilm proliferation, optimizing the microhabitat for silkworm development while minimizing disease incidence.

Spore Load Monitoring in High-Humidity Systems

Wet rearing in sericulture, characterized by high humidity environments, demands rigorous spore load monitoring to prevent pathogen proliferation and ensure optimal silkworm health. In contrast, dry rearing systems inherently reduce spore density, thereby minimizing fungal infections and promoting sustainable environmental management through controlled moisture levels.

Volatile Organic Compound (VOC) Emission Tracking

Wet rearing in sericulture reduces VOC emissions by maintaining higher humidity levels that inhibit the volatilization of organic compounds from mulberry leaves and silkworm excreta. Dry rearing, conversely, accelerates VOC release due to lower moisture, necessitating advanced tracking technologies like gas chromatography-mass spectrometry (GC-MS) for effective environmental management and pollution control.

Zero-Waste Excreta Conversion (ZWEC)

Wet rearing in sericulture enhances Zero-Waste Excreta Conversion (ZWEC) by facilitating the efficient decomposition of silkworm excreta into nutrient-rich organic fertilizers, promoting sustainable waste recycling and reducing environmental pollution. Dry rearing, while simpler, limits ZWEC potential due to slower excreta breakdown and lower microbial activity, thereby lessening its efficacy in environmental management and resource recovery.

Sericin Retention Index

Wet rearing in sericulture enhances the Sericin Retention Index by maintaining optimal humidity and temperature, which reduces sericin degradation during cocoon formation. Dry rearing, while conserving water resources, often leads to lower sericin retention due to increased environmental stress and oxidative damage on the silk fibers.

Integrated Pathogen Suppression (IPS)

Wet rearing in sericulture promotes higher humidity levels that can facilitate the growth of beneficial microorganisms, enhancing Integrated Pathogen Suppression (IPS) through natural microbial antagonism. Dry rearing, by maintaining lower humidity, reduces pathogen proliferation but requires careful environmental control to sustain larval health, making IPS reliant on optimized rearing conditions to prevent disease outbreaks.

Wet Rearing vs Dry Rearing for Environmental Management Infographic

agridif.com

agridif.com