Mulberry silkworms, primarily used in sericulture, produce high-quality, fine silk known for its luster and smooth texture, making them ideal for commercial silk production. Eri silkworms generate a coarser, more durable silk that is naturally thermal and often utilized for eco-friendly textiles. Choosing between mulberry and eri silkworms depends on desired silk characteristics, production scale, and sustainability goals.

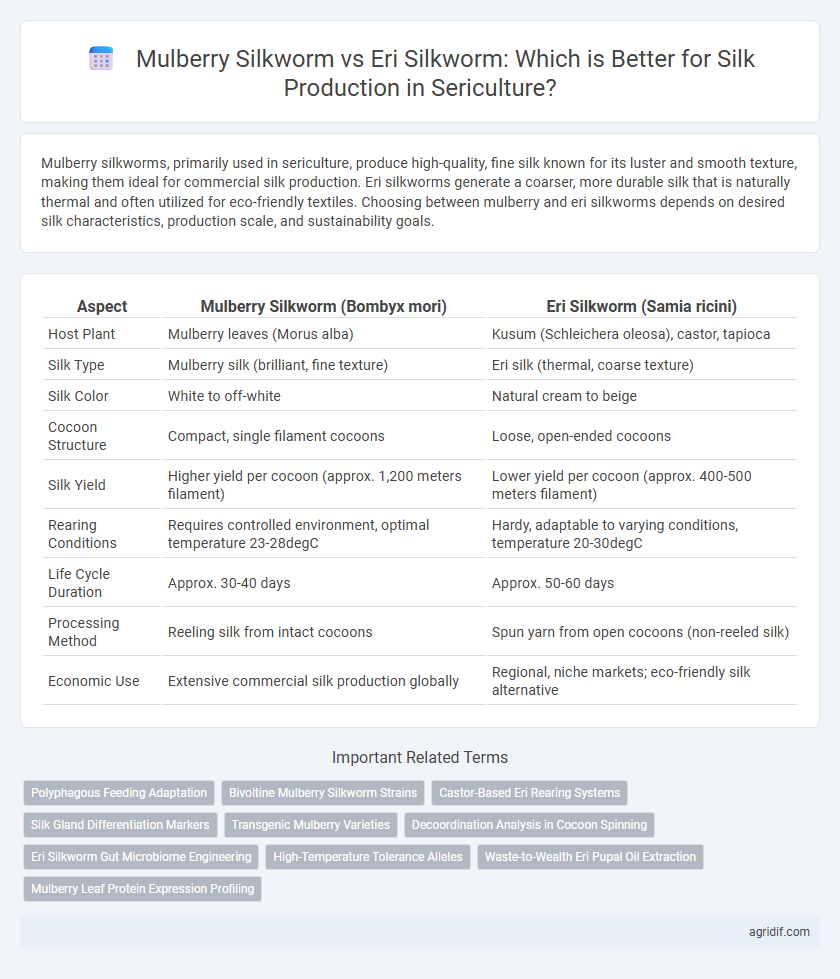

Table of Comparison

| Aspect | Mulberry Silkworm (Bombyx mori) | Eri Silkworm (Samia ricini) |

|---|---|---|

| Host Plant | Mulberry leaves (Morus alba) | Kusum (Schleichera oleosa), castor, tapioca |

| Silk Type | Mulberry silk (brilliant, fine texture) | Eri silk (thermal, coarse texture) |

| Silk Color | White to off-white | Natural cream to beige |

| Cocoon Structure | Compact, single filament cocoons | Loose, open-ended cocoons |

| Silk Yield | Higher yield per cocoon (approx. 1,200 meters filament) | Lower yield per cocoon (approx. 400-500 meters filament) |

| Rearing Conditions | Requires controlled environment, optimal temperature 23-28degC | Hardy, adaptable to varying conditions, temperature 20-30degC |

| Life Cycle Duration | Approx. 30-40 days | Approx. 50-60 days |

| Processing Method | Reeling silk from intact cocoons | Spun yarn from open cocoons (non-reeled silk) |

| Economic Use | Extensive commercial silk production globally | Regional, niche markets; eco-friendly silk alternative |

Introduction to Mulberry and Eri Silkworms

Mulberry silkworms (Bombyx mori) are the primary species used for commercial silk production, prized for their fine, lustrous silk derived exclusively from mulberry leaves. Eri silkworms (Samia ricini) produce coarse, wool-like silk from castor and tapioca leaves, offering a more sustainable and eco-friendly alternative suited for non-mulberry sericulture. Their distinct rearing requirements and silk qualities define their specific applications in the textile industry, with mulberry silk favored for luxury fabrics and eri silk valued for durable, thermal properties.

Taxonomy and Biological Differences

Mulberry silkworms (Bombyx mori) belong to the family Bombycidae, characterized by their dependence on mulberry leaves as the primary food source, whereas Eri silkworms (Samia ricini) from the Saturniidae family primarily feed on castor leaves. Bombyx mori undergoes complete domestication with a univoltine or bivoltine lifecycle, producing fine, lustrous silk, while Samia ricini exhibits partial domestication and produces a coarser, staple type silk with multiple generations per year. Biological differences include variations in cocoon structure, with Bombyx mori spinning compact, filamentous cocoons, contrasting Eri silkworms' loose, open cocoons suitable for spun silk production.

Host Plants: Mulberry vs. Castor and Other Leaves

Mulberry silkworms primarily feed on Morus alba leaves, which enable the production of fine, high-quality silk fibers known for their luster and strength. In contrast, Eri silkworms consume castor leaves and a variety of other host plants such as tapioca and custard apple, resulting in silk that is coarser yet more durable and thermal insulating. The choice of host plants directly influences the texture, yield, and commercial applications of the silk produced by these two silkworm species.

Life Cycle Comparison

The mulberry silkworm (Bombyx mori) completes its life cycle in approximately 45 days, with four distinct stages: egg, larva, pupa, and adult moth, thriving exclusively on mulberry leaves. In contrast, the eri silkworm (Samia ricini) has a longer life cycle of about 60 days, feeding on castor plant leaves and producing non-mulberry silk known for its thermal properties. The faster development and specialized diet of mulberry silkworms make them the primary choice for commercial silk production, whereas the eri silkworm supports niche markets with its unique silk quality.

Silk Quality: Mulberry Silk vs. Eri Silk

Mulberry silkworms produce silk with a finer, smoother texture and higher tensile strength, making mulberry silk the preferred choice for luxury textiles and high-end garments. Eri silkworms generate silk that is coarser and more textured, valued for its thermal insulation and durability rather than softness. The protein composition of mulberry silk, primarily fibroin, contributes to its sheen and elasticity, whereas eri silk contains higher sericin content, resulting in a matte finish and distinct hand feel.

Rearing Practices and Environmental Requirements

Mulberry silkworms require controlled environments with temperatures between 23-28degC and high humidity of 70-85% to optimize cocoon quality, relying heavily on fresh mulberry leaves as their exclusive diet. Eri silkworms, conversely, are more adaptable to varied climatic conditions, thriving in temperatures from 20-30degC and moderate humidity, and can feed on castor leaves and various host plants, making their rearing practices less intensive. The rearing of mulberry silkworms demands specialized infrastructure such as climate-controlled rearing houses, whereas eri silkworm cultivation is more flexible, suitable for open or semi-open environments with minimal facility requirements.

Economic Viability and Yield Potential

Mulberry silkworms (Bombyx mori) dominate global silk production due to their higher yield potential, producing fine, lustrous silk fibers with annual outputs reaching up to 1,750 kg per hectare. Eri silkworms (Samia ricini) yield lower quantities of coarse, less lustrous silk but offer economic viability in marginal areas due to their ability to feed on castor leaves and their resilience to environmental stress. Farmers often choose mulberry silkworms for maximum income and market demand, while eri silkworms provide diversification and lower input costs in niche markets.

Sustainability and Environmental Impact

Mulberry silkworms (Bombyx mori) require intensive cultivation of mulberry plants, which demands high water and chemical inputs, impacting sustainability negatively. Eri silkworms (Samia ricini) feed on various host plants like castor and tapioca, supporting agroforestry practices and reducing monoculture risks, enhancing environmental benefits. Eri silk production involves less chemical usage, lower water consumption, and supports biodiversity, making it a more sustainable option compared to mulberry silk farming.

End-Use Applications of Mulberry and Eri Silk

Mulberry silk, derived from the Bombyx mori silkworm, is prized for its fine texture, high tensile strength, and lustrous sheen, making it ideal for luxury textiles, high-end fashion, and premium upholstery. Eri silk, produced by the Samia ricini silkworm, offers a woolly texture with excellent thermal insulation and durability, suited for warm clothing, home furnishings, and eco-friendly textile products. The differences in fiber properties dictate specific end-use applications, with mulberry silk favored in delicate, smooth fabric requirements and eri silk preferred for versatile, sustainable, and cozy fabric solutions.

Market Trends and Consumer Preferences

Mulberry silkworm silk dominates global sericulture markets due to its superior fiber quality and widespread industrial applications, driving higher consumer demand and premium pricing. Eri silkworm silk, though less lustrous, appeals to niche markets valuing eco-friendliness and ethical production, creating growing interest in sustainable fashion sectors. Current market trends show increasing diversification as consumers prioritize both high-end mulberry silk and eco-conscious eri silk products.

Related Important Terms

Polyphagous Feeding Adaptation

The Eri silkworm exhibits notable polyphagous feeding adaptation, enabling it to consume a variety of host plants beyond mulberry leaves, unlike the Mulberry silkworm which is strictly monophagous and relies solely on Morus species for optimal silk production. This feeding versatility of Eri silkworms supports sustainable sericulture in regions where mulberry cultivation is limited, broadening the scope for silk yield diversification.

Bivoltine Mulberry Silkworm Strains

Bivoltine mulberry silkworm strains produce superior quality silk with fine, long, and lustrous fibers, making them highly preferred for commercial silk production compared to Eri silkworms, which yield coarser and staple fiber silk. The mulberry silkworm's reliance on Morus alba leaves and its bivoltine lifecycle contribute to higher silk yield and enhanced raw silk quality in sericulture.

Castor-Based Eri Rearing Systems

Mulberry silkworms (Bombyx mori) produce high-quality, fine silk with a global market dominance due to their diet exclusively based on mulberry leaves, whereas Eri silkworms (Samia ricini) thrive on castor leaves, making castor-based Eri rearing systems sustainable and well-suited for regions unsuitable for mulberry cultivation. Castor-based Eri rearing not only supports eco-friendly sericulture but also yields coarse, durable silk favored for thermal textiles and handloom products, providing economic benefits to rural communities.

Silk Gland Differentiation Markers

Mulberry silkworms exhibit higher expression of fibroin and sericin genes, key silk gland differentiation markers that enhance the quality and quantity of silk production. In contrast, Eri silkworms show distinct silk gland marker profiles with increased sericin diversity, contributing to their coarse silk's unique texture and durability.

Transgenic Mulberry Varieties

Transgenic mulberry varieties enhance the nutritional quality of leaves, significantly boosting the growth and silk yield of mulberry silkworms (Bombyx mori) compared to eri silkworms (Samia ricini), which primarily feed on castor and som plants. This genetic modification in mulberry plants improves resistance to pests and environmental stress, resulting in higher quality and quantity of silk production in commercial sericulture.

Decoordination Analysis in Cocoon Spinning

Decoordination analysis in cocoon spinning reveals that mulberry silkworms (Bombyx mori) exhibit a highly synchronized spinning behavior resulting in compact, uniform cocoons ideal for high-quality silk production. In contrast, eri silkworms (Samia ricini) show less precise decordination, producing looser, coarse cocoons suited for durable eri silk but with lower tensile strength compared to mulberry silk.

Eri Silkworm Gut Microbiome Engineering

Eri silkworm gut microbiome engineering enhances nutrient absorption and improves silk yield by optimizing beneficial microbial communities, offering a sustainable alternative to traditional mulberry silkworm cultivation. Targeted manipulation of Eri silkworm gut microbiota boosts resistance to pathogens and supports efficient digestion of non-mulberry host plants, advancing sericulture diversification.

High-Temperature Tolerance Alleles

Mulberry silkworms (Bombyx mori) possess limited high-temperature tolerance alleles, rendering them more susceptible to thermal stress during silk production, whereas Eri silkworms (Samia ricini) exhibit a higher frequency of heat-resilient alleles that enable sustained cocoon quality in elevated temperatures. Genetic studies highlight that Eri silkworm populations harbor specific heat shock protein (HSP) gene variants, enhancing their adaptability and productivity in regions with fluctuating or high-temperature climates.

Waste-to-Wealth Eri Pupal Oil Extraction

Mulberry silkworms primarily produce high-quality mulberry silk, while Eri silkworms yield eri silk with unique thermal properties and durability. Eri silkworm pupae, often considered sericulture waste, are increasingly utilized for extracting eri pupal oil, a valuable by-product rich in essential fatty acids that supports sustainable waste-to-wealth initiatives in silk production.

Mulberry Leaf Protein Expression Profiling

Mulberry silkworms exhibit distinct mulberry leaf protein expression profiles that enhance their silk production efficiency compared to Eri silkworms, which feed on castor leaves expressing different protein patterns less conducive to high-quality silk synthesis. Proteomic analyses reveal that specific mulberry leaf proteins upregulate fibroin and sericin gene expression in mulberry silkworms, optimizing silk fiber yield and quality.

Mulberry silkworm vs Eri silkworm for silk production Infographic

agridif.com

agridif.com