Axial-flow threshers efficiently process grains by feeding crop material along the axis, resulting in higher capacity and reduced grain damage due to continuous flow. Radial-flow threshers, however, utilize tangential feeding with a radial arrangement that offers better separation and cleaning, especially suitable for crops with tougher threshing requirements. Choosing between axial-flow and radial-flow threshers depends on crop type, throughput needs, and desired grain quality in agricultural engineering applications.

Table of Comparison

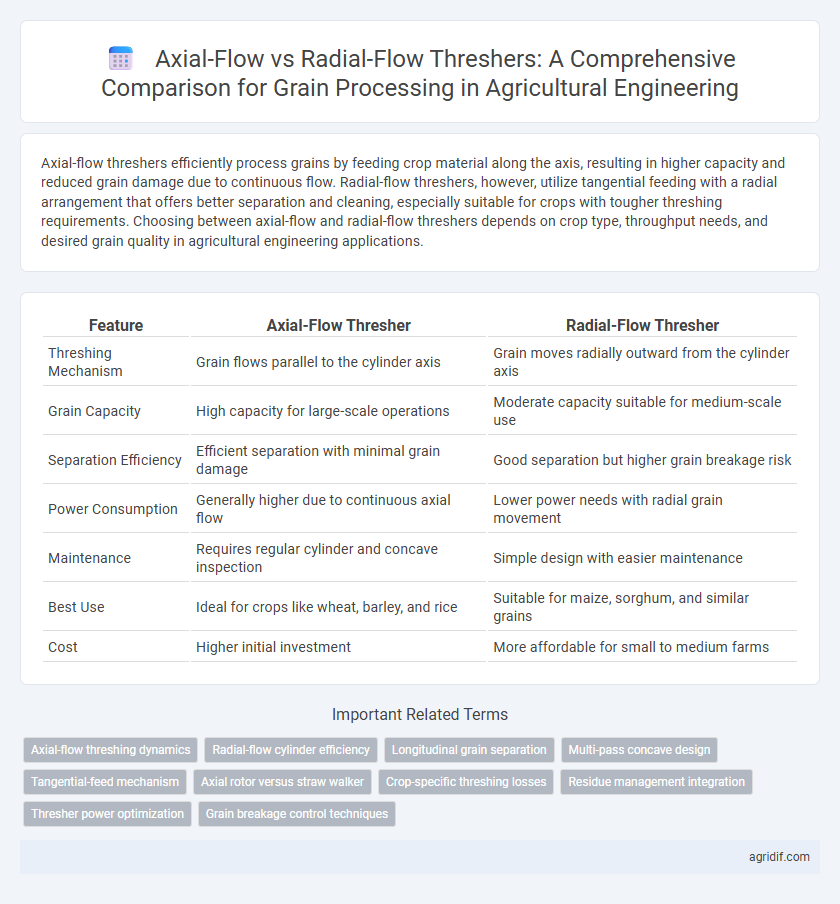

| Feature | Axial-Flow Thresher | Radial-Flow Thresher |

|---|---|---|

| Threshing Mechanism | Grain flows parallel to the cylinder axis | Grain moves radially outward from the cylinder axis |

| Grain Capacity | High capacity for large-scale operations | Moderate capacity suitable for medium-scale use |

| Separation Efficiency | Efficient separation with minimal grain damage | Good separation but higher grain breakage risk |

| Power Consumption | Generally higher due to continuous axial flow | Lower power needs with radial grain movement |

| Maintenance | Requires regular cylinder and concave inspection | Simple design with easier maintenance |

| Best Use | Ideal for crops like wheat, barley, and rice | Suitable for maize, sorghum, and similar grains |

| Cost | Higher initial investment | More affordable for small to medium farms |

Introduction to Grain Threshing Technologies

Axial-flow threshers use a cylindrical rotor that moves grain along its axis, ensuring high throughput and minimal grain damage, ideal for large-scale grain processing. Radial-flow threshers employ a tangential or radial movement of crops against the threshing drum, offering effective separation but often higher grain breakage. Both technologies optimize grain threshing efficiency by balancing throughput, grain quality, and operational adaptability depending on crop type and processing scale.

Overview of Axial-Flow Threshers

Axial-flow threshers use a rotating cylinder with helical rasp bars to separate grains by pulling the crop through an axial cylinder, resulting in gentle grain handling and higher throughput capacity. These threshers are particularly efficient for processing crops like wheat, rice, and maize, minimizing grain damage and losses compared to radial-flow threshers. Their design allows continuous crop flow, making them preferred for large-scale agricultural grain processing operations.

Overview of Radial-Flow Threshers

Radial-flow threshers are designed with concave and cylinder arrangements that enhance grain separation efficiency by allowing grains to move outward radially during threshing. This design minimizes grain damage and reduces the amount of broken kernels compared to axial-flow threshers. In grain processing, radial-flow threshers improve throughput and ensure higher quality output by providing gentler threshing action suited for delicate crops like wheat and rice.

Key Design Differences: Axial vs Radial Threshers

Axial-flow threshers utilize a cylindrical rotor with parallel spike-tooth bars that move grain and straw along the rotor axis, providing continuous and uniform threshing suitable for high-capacity grain processing. Radial-flow threshers feature a tangential or radial rotor where grain enters perpendicularly to the rotor axis, allowing more aggressive threshing action but with potential grain damage due to increased impact. The key design difference lies in grain flow direction and threshing mechanism, influencing efficiency, grain quality, and suitability for various crop types.

Grain Separation Efficiency Comparison

Axial-flow threshers exhibit higher grain separation efficiency by using continuous crop flow and a longer threshing drum, which reduces grain damage and loss compared to radial-flow threshers. Radial-flow threshers rely on a rotating cage that delivers moderate separation but often results in increased grain breakage and lower throughput. Optimizing axial-flow threshing systems enhances productivity by minimizing unthreshed grain and maximizing clean grain output during large-scale grain processing.

Power and Energy Requirements

Axial-flow threshers generally require lower power consumption compared to radial-flow threshers due to their continuous and streamlined grain processing mechanism. Radial-flow threshers often demand higher energy input as their design involves more complex grain separation stages causing increased mechanical resistance. Optimizing power efficiency in axial-flow threshers makes them preferable for large-scale grain processing where energy savings are critical.

Impact on Grain Quality and Breakage

Axial-flow threshers utilize a continuous, axial threshing action that minimizes grain breakage by providing gentler separation, resulting in higher grain quality and reduced kernel damage. Radial-flow threshers employ a more aggressive, radial impact mechanism that often leads to increased grain breakage and lower overall grain quality due to higher mechanical stress during processing. Choosing axial-flow threshers significantly improves the preservation of grain integrity, essential for maintaining market value and processing efficiency in agricultural operations.

Maintenance and Operational Considerations

Axial-flow threshers typically require less frequent maintenance due to their simpler design and fewer moving parts, reducing downtime during peak harvest periods. Radial-flow threshers demand meticulous inspection of the concave and drum clearance to prevent grain damage and ensure optimal separation efficiency. Operationally, axial-flow models offer smoother grain flow and lower power consumption, while radial-flow threshers provide better adaptability to different crop types but with higher maintenance complexity.

Cost Analysis: Initial Investment and Operating Expenses

Axial-flow threshers generally have a higher initial investment cost due to advanced design and greater processing capacity compared to radial-flow threshers. Operating expenses for axial-flow threshers tend to be lower, driven by improved fuel efficiency and reduced grain damage, whereas radial-flow threshers incur higher maintenance costs from simpler but less durable mechanical components. Evaluating total cost of ownership in grain processing reveals axial-flow threshers offer better long-term economic benefits despite the steeper upfront investment.

Suitability for Different Crop Types

Axial-flow threshers excel in processing long-stemmed crops like wheat and barley by providing continuous threshing without excessive grain damage. Radial-flow threshers are more suitable for crops with dense, compact ears such as maize and sorghum, as their design ensures gentle separation and reduced kernel breakage. Selecting the appropriate thresher type enhances efficiency and grain quality based on specific crop characteristics.

Related Important Terms

Axial-flow threshing dynamics

Axial-flow threshers utilize a rotating cylinder parallel to the grain flow, enabling continuous and high-capacity threshing with minimal grain damage due to consistent friction and impact forces. Their dynamic threshing mechanism efficiently separates grain from the crop by exploiting axial feeding, which enhances throughput and reduces power consumption compared to radial-flow threshers.

Radial-flow cylinder efficiency

Radial-flow threshers achieve higher grain separation efficiency due to their design, which allows for more effective grain and straw separation by directing material flow perpendicularly to the cylinder axis, reducing grain damage. This improved flow dynamics in radial-flow cylinders lead to better threshing performance and reduced grain loss compared to axial-flow threshers.

Longitudinal grain separation

Axial-flow threshers use a cylindrical rotor to create a continuous longitudinal separation of grain, enhancing throughput and reducing grain damage. In contrast, radial-flow threshers separate grain by forcing crop material radially against concave surfaces, which can result in more localized threshing but less uniform longitudinal processing.

Multi-pass concave design

Axial-flow threshers utilize a multi-pass concave design that allows grains to pass through successive concave sections, enhancing threshing efficiency by improving grain separation and reducing damage. Radial-flow threshers typically employ a single-pass concave setup, which limits throughput but offers simpler maintenance compared to the multi-pass design of axial-flow threshers.

Tangential-feed mechanism

The axial-flow thresher utilizes a tangential-feed mechanism that gently directs grain along the cylinder axis, resulting in efficient separation with minimal grain damage and improved throughput for high-yield crops. In contrast, radial-flow threshers employ a tangential-feed system that feeds grain into the threshing drum from the side, offering robust handling of diverse crop residues but with increased potential for kernel breakage and lower efficiency in fine separation.

Axial rotor versus straw walker

Axial-flow threshers utilize a high-speed rotating axial rotor to efficiently separate grain from crop material, providing continuous threshing action that reduces grain damage and increases throughput compared to radial-flow models. Straw walkers in radial-flow threshers mechanically lift and shake the crop residues to separate grain, but often cause higher grain breakage and lower processing capacity than the smooth, aerodynamic action of the axial rotor.

Crop-specific threshing losses

Axial-flow threshers exhibit lower threshing losses in crops like wheat and barley due to their continuous, high-speed drum mechanism that gently separates grains from the straw. Radial-flow threshers, with their tangential grain separation approach, tend to increase threshing losses in delicate crops such as rice and maize, where grain breakage and incomplete threshing are common challenges.

Residue management integration

Axial-flow threshers offer efficient processing with uniform grain separation, enabling better integration of residue management systems by producing evenly sized straw conducive for mulching and bioenergy applications. Radial-flow threshers, while providing high throughput, tend to produce more fragmented residues that can complicate residue collection and reduce effectiveness in conservation tillage and soil conditioning practices.

Thresher power optimization

Axial-flow threshers optimize power efficiency by using a continuous, high-speed rotary mechanism that minimizes grain damage and maximizes throughput, ideal for large-scale grain processing. Radial-flow threshers, while simpler and lower-cost, consume more power due to their intermittent impact action, making them less efficient for high-capacity operations requiring optimized energy use.

Grain breakage control techniques

Axial-flow threshers reduce grain breakage by utilizing a smooth, continuous cylindrical rotor that gently separates grains through controlled concave clearance and adjustable rotor speed, enhancing kernel integrity. Radial-flow threshers rely on a stationary concave and radial rotor design that employs impact and friction forces, often requiring precise control of clearance and threshing parameters to minimize grain damage effectively.

Axial-flow thresher vs Radial-flow thresher for grain processing Infographic

agridif.com

agridif.com