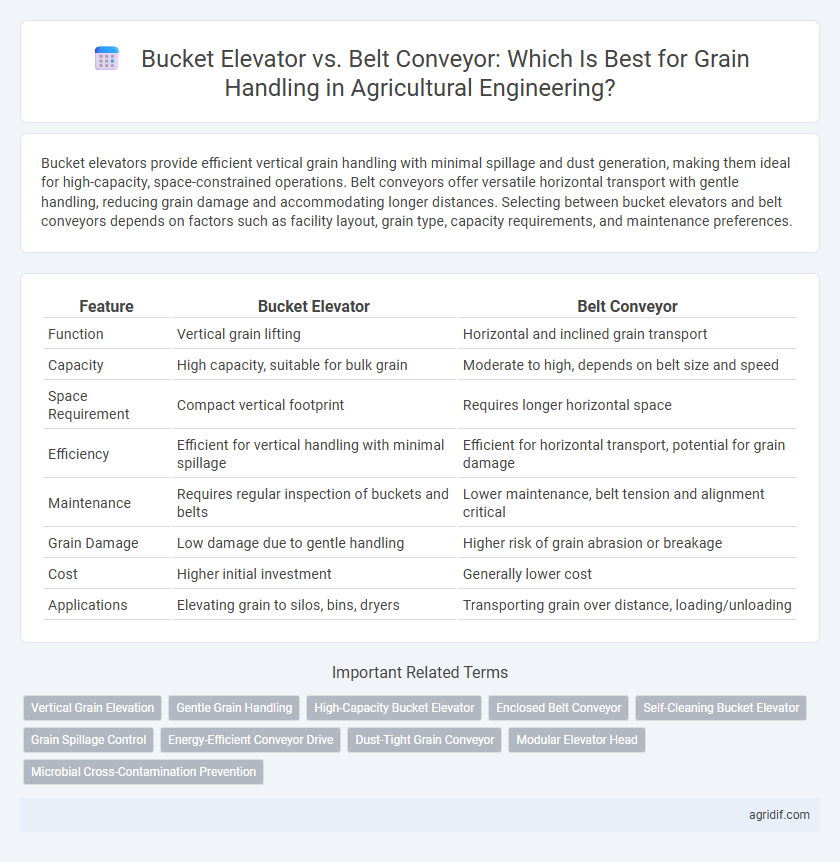

Bucket elevators provide efficient vertical grain handling with minimal spillage and dust generation, making them ideal for high-capacity, space-constrained operations. Belt conveyors offer versatile horizontal transport with gentle handling, reducing grain damage and accommodating longer distances. Selecting between bucket elevators and belt conveyors depends on factors such as facility layout, grain type, capacity requirements, and maintenance preferences.

Table of Comparison

| Feature | Bucket Elevator | Belt Conveyor |

|---|---|---|

| Function | Vertical grain lifting | Horizontal and inclined grain transport |

| Capacity | High capacity, suitable for bulk grain | Moderate to high, depends on belt size and speed |

| Space Requirement | Compact vertical footprint | Requires longer horizontal space |

| Efficiency | Efficient for vertical handling with minimal spillage | Efficient for horizontal transport, potential for grain damage |

| Maintenance | Requires regular inspection of buckets and belts | Lower maintenance, belt tension and alignment critical |

| Grain Damage | Low damage due to gentle handling | Higher risk of grain abrasion or breakage |

| Cost | Higher initial investment | Generally lower cost |

| Applications | Elevating grain to silos, bins, dryers | Transporting grain over distance, loading/unloading |

Introduction to Grain Handling Systems

Bucket elevators provide vertical grain transport using a series of buckets attached to a belt or chain, ideal for elevating grain in confined spaces with minimal spillage and damage. Belt conveyors move grain horizontally or on a slight incline, offering continuous flow and high capacity for bulk grain handling over longer distances. Selecting between bucket elevators and belt conveyors depends on factors like grain type, transport distance, space constraints, and maintenance requirements within agricultural grain handling systems.

Overview of Bucket Elevators in Agriculture

Bucket elevators provide efficient vertical transportation of grain, utilizing a series of buckets attached to a belt or chain to move bulk materials with minimal spillage and damage. These systems are essential in agricultural settings for elevating grain from lower levels to storage bins or processing equipment, ensuring consistent flow rates and reducing grain degradation compared to belt conveyors. Their robust design handles various grain types and moisture levels, making them a reliable choice for grain handling in farming operations.

Belt Conveyors: Function and Application in Grain Handling

Belt conveyors in grain handling provide efficient horizontal and inclined transport of bulk materials such as wheat, corn, and rice with minimal grain damage. Their continuous belt design allows for high-capacity throughput, reducing operational downtime in agricultural processing facilities. Common applications include grain drying, milling, and loading operations, where consistent flow and gentle handling preserve grain quality.

Key Differences Between Bucket Elevators and Belt Conveyors

Bucket elevators are designed for vertical grain handling with efficient lifting capacity and minimal grain damage, while belt conveyors excel in horizontal and inclined transport with continuous flow and lower maintenance. Bucket elevators use buckets attached to a belt or chain to carry grain upward, making them ideal for high elevation transfers, whereas belt conveyors use a continuous belt for smooth, bulk transport over longer distances. The choice depends on factors like elevation height, grain type, throughput volume, and spatial layout of the grain handling facility.

Grain Throughput Capacity Comparison

Bucket elevators offer higher grain throughput capacity compared to belt conveyors due to their vertical lift design, enabling efficient transport of large volumes of grain at faster speeds. Belt conveyors provide steady horizontal movement but are generally limited by lower incline angles and slower throughput rates, making them less suitable for high-capacity grain handling. Optimization of grain throughput capacity depends on elevator bucket size, belt speed, and conveyor length, with bucket elevators preferred in large-scale agricultural operations requiring rapid and vertical grain transfer.

Energy Efficiency and Operational Costs

Bucket elevators typically offer higher energy efficiency for grain handling by minimizing friction losses and providing vertical lifting with less power consumption, resulting in lower operational costs compared to belt conveyors. Belt conveyors require more energy due to greater friction and longer horizontal transport, which increases wear and maintenance expenses over time. Choosing bucket elevators can reduce overall energy usage by up to 30%, significantly lowering operational costs in large-scale grain handling systems.

Maintenance Requirements and Durability

Bucket elevators typically require more frequent inspections and lubrication due to their numerous moving parts and higher mechanical complexity compared to belt conveyors. Belt conveyors offer enhanced durability with fewer maintenance demands, benefiting from simpler designs and resistance to wear caused by grain abrasion. Selecting the right system depends on balancing maintenance resources with operational longevity in grain handling environments.

Space and Installation Considerations

Bucket elevators offer a compact vertical design ideal for limited floor space, requiring minimal horizontal area compared to belt conveyors, which need longer layout lengths for inclined or horizontal transport. Installation of bucket elevators involves precise alignment and securing of vertical legs, often demanding less groundwork and support structures than belt conveyors that require tensioning systems, pulleys, and idler rollers over extended spans. Selecting between these systems depends on available installation space, structural support capacity, and the desired grain handling flow direction in agricultural facilities.

Suitability for Various Grain Types

Bucket elevators excel in handling a wide variety of grain types, including fragile and irregularly shaped kernels, due to their gentle lifting mechanism that reduces grain damage and maintains quality. Belt conveyors are more suitable for bulk transfer of grains with uniform size and hardness, offering high capacity and efficiency over longer horizontal distances but are less effective with fragile grains. Selecting the right equipment depends on grain characteristics like moisture content, kernel size, and susceptibility to breakage to optimize handling efficiency and minimize losses.

Choosing the Right System for Agricultural Needs

Bucket elevators provide efficient vertical grain handling with minimal damage, ideal for high-capacity storage and processing facilities, while belt conveyors offer greater flexibility for horizontal or inclined transport over longer distances. The choice between bucket elevators and belt conveyors depends on factors like grain type, required capacity, installation site layout, and maintenance considerations. Evaluating these parameters ensures optimal system performance, cost-effectiveness, and grain quality preservation in agricultural operations.

Related Important Terms

Vertical Grain Elevation

Bucket elevators provide efficient vertical grain elevation with minimal spillage and reduced grain damage, making them ideal for high-capacity grain handling in confined spaces. Belt conveyors excel in horizontal or slight incline transport but lack the vertical lifting efficiency and space-saving advantages of bucket elevators in grain processing facilities.

Gentle Grain Handling

Bucket elevators provide gentle grain handling by minimizing grain impact and reducing bruising through vertical lifting with individual buckets, making them ideal for fragile grains. Belt conveyors offer continuous horizontal movement but may cause more grain abrasion and damage due to friction and grain-to-grain contact during transport.

High-Capacity Bucket Elevator

High-capacity bucket elevators excel in vertical grain handling by efficiently lifting large volumes with minimal spillage and reduced grain damage compared to belt conveyors, which are better suited for horizontal transport over long distances. Their robust construction and high throughput rates make them ideal for grain elevators, silos, and large-scale agricultural storage facilities requiring rapid vertical movement.

Enclosed Belt Conveyor

Enclosed belt conveyors offer superior protection against grain contamination and environmental exposure compared to bucket elevators, making them ideal for maintaining grain quality in agricultural engineering. Their continuous, enclosed design minimizes spillage and dust generation, enhancing operational efficiency and safety in grain handling processes.

Self-Cleaning Bucket Elevator

The self-cleaning bucket elevator excels in grain handling by minimizing product spillage and reducing contamination risks, ensuring efficient vertical lifting with minimal grain damage. Unlike traditional belt conveyors, its design promotes continuous material flow and easy maintenance, making it ideal for handling sticky or oversized grain particles in agricultural engineering.

Grain Spillage Control

Bucket elevators provide superior grain spillage control compared to belt conveyors by encapsulating grain within discrete buckets, minimizing product exposure and reducing losses during vertical transport. In contrast, belt conveyors are more prone to spillage as grains can scatter along the belt edges, especially at transfer points and during changes in incline.

Energy-Efficient Conveyor Drive

Bucket elevators typically offer higher energy efficiency for vertical grain handling due to their compact design and reduced friction losses, resulting in lower power consumption compared to belt conveyors. Belt conveyors, while versatile for horizontal transport, often require more energy to overcome belt tension and rolling resistance, making bucket elevators a preferred choice for energy-efficient grain conveyance in vertical applications.

Dust-Tight Grain Conveyor

Bucket elevators provide a dust-tight grain conveyor solution by enclosing grain within vertical buckets, minimizing spillage and airborne dust during lifting and transfer. Belt conveyors lack complete sealing, making bucket elevators more effective for maintaining air quality and cleanliness in grain handling operations.

Modular Elevator Head

The modular elevator head in a bucket elevator offers precise grain handling with customizable configurations for various capacities and grain types, ensuring minimal grain breakage and dust generation. Belt conveyors lack this modular adaptability, often resulting in lower efficiency and higher maintenance in dynamic grain handling environments.

Microbial Cross-Contamination Prevention

Bucket elevators minimize microbial cross-contamination by reducing grain exposure to external contaminants through enclosed vertical transport, while belt conveyors often have larger surface areas and open belts that increase the risk of microbial buildup and contamination. Implementing smooth surfaces and regular cleaning protocols in bucket elevators enhances hygiene, making them more effective for preventing microbial contamination in grain handling operations.

Bucket elevator vs Belt conveyor for grain handling Infographic

agridif.com

agridif.com