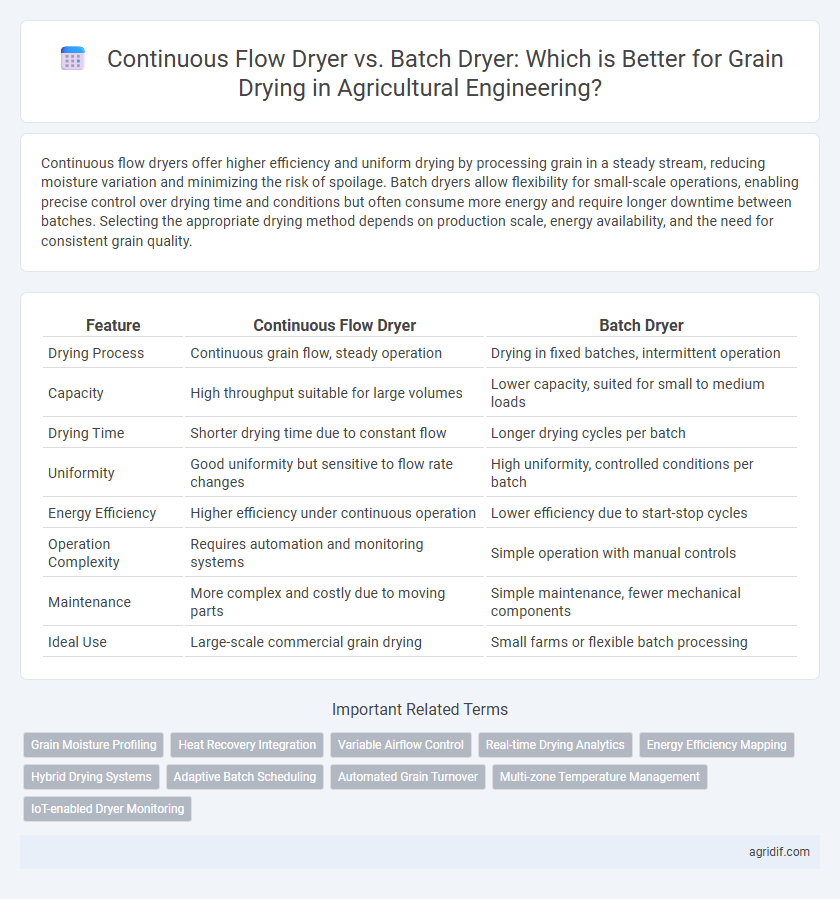

Continuous flow dryers offer higher efficiency and uniform drying by processing grain in a steady stream, reducing moisture variation and minimizing the risk of spoilage. Batch dryers allow flexibility for small-scale operations, enabling precise control over drying time and conditions but often consume more energy and require longer downtime between batches. Selecting the appropriate drying method depends on production scale, energy availability, and the need for consistent grain quality.

Table of Comparison

| Feature | Continuous Flow Dryer | Batch Dryer |

|---|---|---|

| Drying Process | Continuous grain flow, steady operation | Drying in fixed batches, intermittent operation |

| Capacity | High throughput suitable for large volumes | Lower capacity, suited for small to medium loads |

| Drying Time | Shorter drying time due to constant flow | Longer drying cycles per batch |

| Uniformity | Good uniformity but sensitive to flow rate changes | High uniformity, controlled conditions per batch |

| Energy Efficiency | Higher efficiency under continuous operation | Lower efficiency due to start-stop cycles |

| Operation Complexity | Requires automation and monitoring systems | Simple operation with manual controls |

| Maintenance | More complex and costly due to moving parts | Simple maintenance, fewer mechanical components |

| Ideal Use | Large-scale commercial grain drying | Small farms or flexible batch processing |

Introduction to Grain Drying Techniques in Agriculture

Continuous flow dryers offer consistent drying of grains through a steady movement of kernels across heated air, improving efficiency and uniformity compared to batch dryers, which process grain in separate, time-consuming cycles. Batch dryers allow precise control over smaller grain quantities, offering flexibility but at the cost of longer drying times and potential moisture variability. Selecting the appropriate drying method depends on factors such as grain type, moisture content, drying capacity, and operational scale within agricultural engineering practices.

Overview of Continuous Flow Dryers

Continuous flow dryers operate by moving grain steadily through a heated chamber, allowing for uniform moisture removal and higher throughput compared to batch dryers. These systems enable continuous processing without interrupting the drying cycle, which enhances efficiency and reduces labor costs in large-scale grain drying operations. The precise control of airflow and temperature in continuous flow dryers improves grain quality while minimizing overheating and energy consumption.

Overview of Batch Dryers

Batch dryers offer precise control over drying conditions by processing grain in discrete quantities, making them suitable for small to medium-scale operations. They allow for uniform moisture reduction and can handle different grain types without cross-contamination. Typically, batch dryers have lower initial costs but require more labor and longer drying times compared to continuous flow dryers.

Efficiency Comparison: Continuous Flow vs Batch Drying

Continuous flow dryers offer higher efficiency for grain drying by ensuring a steady, uniform airflow and consistent moisture removal, reducing drying time and energy consumption compared to batch dryers. Batch dryers, although simpler and more flexible for small-scale operations, often experience uneven drying and longer processing times, leading to higher energy use per unit of grain. The continuous flow system optimizes throughput and energy efficiency, making it a preferred choice for large-scale grain drying in agricultural engineering.

Energy Consumption in Continuous and Batch Grain Dryers

Continuous flow dryers typically exhibit lower energy consumption per unit of grain dried due to their steady-state operation and efficient heat transfer mechanisms. Batch dryers often consume more energy as they require repeated heating cycles and intermittent loading, causing thermal fluctuations and energy losses. Optimizing airflow and temperature control in continuous flow dryers further enhances energy efficiency compared to the cyclical nature of batch drying processes.

Grain Quality Preservation: Continuous vs Batch Dryers

Continuous flow dryers maintain consistent temperature and airflow, reducing thermal stress and preserving grain quality more effectively than batch dryers. Batch dryers expose grain to fluctuating conditions during loading and unloading, increasing the risk of uneven drying and potential quality degradation. Industrial studies show that continuous dryers result in lower moisture variability and higher germination rates, enhancing overall grain quality preservation.

Capacity and Throughput Considerations

Continuous flow dryers provide higher capacity and throughput compared to batch dryers, enabling the processing of large grain volumes efficiently in a steady stream. Batch dryers operate on fixed quantities per cycle, limiting throughput and requiring more time for loading, drying, and unloading phases. Selecting between continuous and batch drying depends on production scale, with continuous dryers favored for large-scale operations due to their superior drying capacity and consistent flow rate.

Cost Analysis: Initial Investment and Operating Expenses

Continuous flow dryers require higher initial investment due to complex engineering and larger equipment size but offer lower operating costs through energy efficiency and reduced labor needs. Batch dryers have lower upfront costs, making them accessible for small-scale operations, but incur higher operating expenses because of increased manual labor and longer drying cycles. Evaluating total cost of ownership involves balancing capital expenditure against ongoing energy and maintenance expenses specific to grain drying capacity and throughput.

Suitability for Different Farm Scales and Operations

Continuous flow dryers offer high efficiency and consistent grain quality, making them ideal for large-scale commercial farms with high throughput demands. Batch dryers provide greater flexibility and are more suitable for small to medium-sized farms, allowing farmers to dry varying quantities in separate loads without constant operation. Selection depends on operational scale and drying volume, with continuous dryers optimizing large operations and batch dryers supporting diverse, smaller-scale farming needs.

Decision Factors: Selecting the Right Grain Drying System

Selecting the right grain drying system depends on factors such as drying capacity, energy efficiency, and operational control. Continuous flow dryers offer higher throughput and consistent drying, making them suitable for large-scale operations, while batch dryers provide flexibility and are ideal for smaller quantities or varying grain types. Cost considerations, maintenance requirements, and available drying time also influence the decision between continuous flow and batch drying systems.

Related Important Terms

Grain Moisture Profiling

Continuous flow dryers provide uniform grain moisture profiling by maintaining steady airflow and consistent drying conditions throughout the process, enhancing grain quality and reducing spoilage. Batch dryers exhibit variable moisture content due to intermittent drying cycles, which can lead to uneven moisture distribution and potential grain damage.

Heat Recovery Integration

Continuous flow dryers offer superior heat recovery integration by utilizing exhaust air systems with heat exchangers to reclaim thermal energy, enhancing energy efficiency and reducing operational costs. Batch dryers typically lack advanced heat recovery mechanisms, resulting in higher fuel consumption and less sustainable grain drying processes.

Variable Airflow Control

Continuous flow dryers for grain drying enable precise variable airflow control, optimizing moisture removal efficiency and reducing drying time compared to batch dryers. Variable airflow in continuous dryers enhances energy efficiency by adjusting air volume based on real-time grain moisture content and drying stages.

Real-time Drying Analytics

Continuous flow dryers leverage real-time drying analytics to optimize moisture removal by monitoring temperature, airflow, and grain moisture content simultaneously, resulting in enhanced efficiency and uniform drying. Batch dryers, while effective for smaller volumes, lack integrated real-time data feedback, often leading to inconsistent drying and increased energy consumption.

Energy Efficiency Mapping

Continuous flow dryers achieve higher energy efficiency in grain drying by maintaining a steady airflow and temperature, reducing heat loss and drying time compared to batch dryers. Batch dryers exhibit lower energy efficiency due to intermittent operation, frequent heating cycles, and uneven airflow distribution that increase overall fuel consumption and drying duration.

Hybrid Drying Systems

Hybrid drying systems combine the efficiency of continuous flow dryers with the precision of batch dryers to optimize grain moisture content and energy consumption. These systems leverage continuous airflow for large-volume drying while using controlled batch processing to enhance uniformity and minimize kernel damage, improving overall grain quality.

Adaptive Batch Scheduling

Continuous flow dryers offer higher throughput and uniform drying for large-scale grain processing, while batch dryers provide flexibility and precise control through adaptive batch scheduling, optimizing drying time and energy usage based on grain moisture content and batch size. Adaptive batch scheduling enhances batch dryer efficiency by dynamically adjusting drying cycles to accommodate variable grain properties, reducing spoilage and improving overall grain quality.

Automated Grain Turnover

Continuous flow dryers enable automated grain turnover by maintaining a steady grain movement through the drying chamber, improving uniform moisture reduction and reducing manual handling. Batch dryers require manual loading and unloading, limiting automation and causing inconsistent drying due to interrupted grain turnover.

Multi-zone Temperature Management

Continuous flow dryers utilize multi-zone temperature management to precisely control heat distribution along the drying path, enhancing grain quality and energy efficiency, while batch dryers offer less uniform temperature zones that may cause inconsistent drying and increased moisture variability in grains. Advanced multi-zone controls in continuous flow systems optimize moisture removal and reduce thermal damage by adjusting temperatures based on real-time grain moisture content and airflow dynamics.

IoT-enabled Dryer Monitoring

Continuous flow dryers equipped with IoT-enabled monitoring systems provide real-time data on temperature, humidity, and airflow, optimizing grain drying efficiency and reducing moisture content variability. Batch dryers, while simpler, lack integrated IoT capabilities, limiting precision in moisture control and operation automation compared to continuous flow dryers.

Continuous flow dryer vs Batch dryer for grain drying Infographic

agridif.com

agridif.com