Grain dryers offer precise control over temperature and humidity, significantly reducing drying time and minimizing grain quality loss compared to traditional sun drying. Unlike sun drying, which depends heavily on weather conditions and increases the risk of contamination and spoilage, mechanical drying ensures consistent moisture levels, improving storage longevity and reducing post-harvest losses. Efficient grain drying technology enhances overall farm productivity and supports better market prices by maintaining optimal grain quality.

Table of Comparison

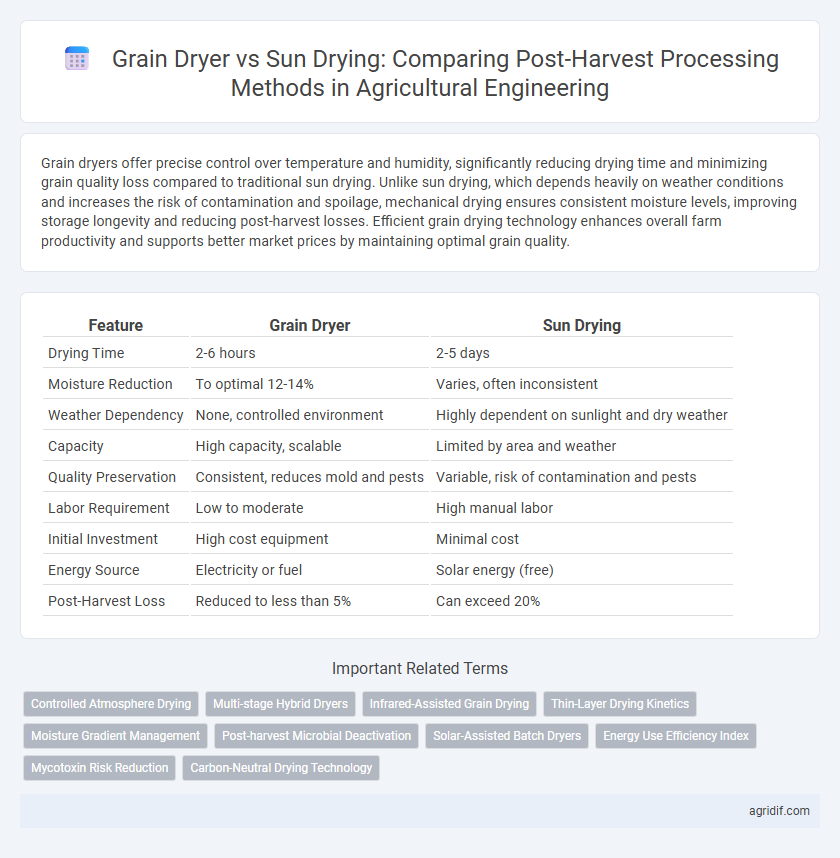

| Feature | Grain Dryer | Sun Drying |

|---|---|---|

| Drying Time | 2-6 hours | 2-5 days |

| Moisture Reduction | To optimal 12-14% | Varies, often inconsistent |

| Weather Dependency | None, controlled environment | Highly dependent on sunlight and dry weather |

| Capacity | High capacity, scalable | Limited by area and weather |

| Quality Preservation | Consistent, reduces mold and pests | Variable, risk of contamination and pests |

| Labor Requirement | Low to moderate | High manual labor |

| Initial Investment | High cost equipment | Minimal cost |

| Energy Source | Electricity or fuel | Solar energy (free) |

| Post-Harvest Loss | Reduced to less than 5% | Can exceed 20% |

Introduction to Post-Harvest Grain Drying Methods

Grain drying is a critical post-harvest process that preserves quality and prevents spoilage by reducing moisture content to safe storage levels. Mechanical grain dryers offer controlled drying environments with consistent temperature and airflow, enabling efficient moisture removal in a shorter time compared to traditional sun drying. Sun drying, although cost-effective and widely used in small-scale farming, presents challenges such as prolonged exposure to environmental contaminants and variable drying rates, which can compromise grain quality and increase post-harvest losses.

Overview of Grain Dryers in Modern Agriculture

Grain dryers in modern agriculture utilize controlled heat and airflow to rapidly reduce moisture content, ensuring optimal grain quality and minimizing post-harvest losses. These mechanical systems offer precise moisture control compared to traditional sun drying, reducing drying time from several days to hours and enabling continuous processing regardless of weather conditions. Advanced grain dryers integrate sensors and automation technology, improving energy efficiency and preserving the nutritional value and marketability of stored grains.

Traditional Sun Drying: Process and Practices

Traditional sun drying remains a widely used post-harvest process where grains are spread out on clean, flat surfaces such as tarpaulins or concrete floors to reduce moisture content through natural solar heat and air circulation. This method requires careful monitoring to prevent contamination from dust, pests, and weather elements, which can affect grain quality and storage life. Despite its low cost and simplicity, sun drying is time-consuming and less efficient compared to mechanical grain dryers, making it vulnerable to inconsistent drying and potential post-harvest losses.

Efficiency Comparison: Grain Dryer vs Sun Drying

Grain dryers provide consistent and controlled drying conditions, significantly reducing moisture content in a shorter time compared to sun drying, which relies heavily on weather conditions and can be inconsistent. The efficiency of grain dryers ensures reduced post-harvest losses, enhanced grain quality, and improved storage life, whereas sun drying often results in higher contamination risks and longer drying periods. Energy consumption and operational costs of grain dryers are balanced by faster processing and minimized spoilage, making them more suitable for large-scale agricultural operations.

Impact on Grain Quality and Safety

Grain dryers significantly reduce moisture content quickly and uniformly, minimizing fungal growth and preserving nutritional value compared to sun drying. Sun drying exposes grains to uncontrollable environmental factors such as pests, dust, and variable humidity, increasing contamination risks and quality degradation. Controlled temperature and humidity in grain dryers enhance grain safety, extending shelf life and maintaining market value.

Cost Analysis: Initial Investment and Operating Expenses

Grain dryers require a significant initial investment, often ranging from $5,000 to $50,000 depending on capacity and technology, compared to virtually no upfront cost for sun drying. Operating expenses for grain dryers include energy consumption, maintenance, and labor, averaging $10 to $20 per ton of grain processed, which can be substantial over time. Sun drying minimizes operating costs but risks quality loss and longer drying times, potentially increasing post-harvest losses and reducing overall economic efficiency.

Labor and Time Requirements for Each Method

Grain dryers significantly reduce labor intensity and processing time compared to sun drying, enabling faster moisture reduction and minimizing exposure to weather risks. Sun drying demands extensive manual labor for spreading, turning, and collecting grain, often extending the drying period from several days to weeks. Automated grain dryers streamline post-harvest operations, improve efficiency, and allow for timely grain storage, enhancing overall crop quality and reducing spoilage risks.

Environmental Considerations in Drying Methods

Grain dryers consume significant amounts of energy, often relying on fossil fuels, which can increase carbon emissions compared to sun drying. Sun drying uses natural solar energy, minimizing environmental impact but poses risks of contamination and requires more space and time. Optimizing grain dryer efficiency with renewable energy sources can reduce ecological footprints while ensuring faster, controlled moisture removal.

Suitability for Different Scales of Farming

Grain dryers offer precise moisture control and faster drying times, making them ideal for large-scale commercial farms requiring high throughput and consistent quality. Sun drying, while cost-effective and accessible, suits smallholder farmers with limited resources but involves risks of uneven drying and contamination due to environmental exposure. Choosing between grain dryers and sun drying depends on farm size, investment capacity, and the need for controlled processing to maintain grain quality.

Future Trends in Grain Drying Technology

Grain dryers are evolving with advances in sensor technology and automation, enabling precise moisture control that reduces drying time and energy consumption compared to traditional sun drying methods. Innovations such as solar-assisted grain drying systems integrate renewable energy sources, enhancing sustainability and efficiency in post-harvest processing. Future trends emphasize real-time monitoring and data analytics to optimize drying conditions, improve grain quality, and minimize losses during storage.

Related Important Terms

Controlled Atmosphere Drying

Grain dryers using controlled atmosphere drying regulate temperature, humidity, and oxygen levels to prevent spoilage and maintain grain quality, outperforming traditional sun drying methods that expose crops to environmental contaminants and variable conditions. This technology enhances moisture uniformity and reduces drying time, resulting in higher efficiency and better preservation of nutritional value during post-harvest processing.

Multi-stage Hybrid Dryers

Multi-stage hybrid grain dryers combine controlled temperature and airflow management to significantly enhance drying efficiency and reduce post-harvest losses compared to traditional sun drying methods. These systems optimize moisture removal through sequential drying phases, ensuring uniform grain quality and minimizing spoilage risks in agricultural processing.

Infrared-Assisted Grain Drying

Infrared-assisted grain drying significantly reduces moisture content more uniformly and rapidly compared to traditional sun drying, minimizing post-harvest losses and microbial growth. Its precise temperature control enhances grain quality and energy efficiency, offering a sustainable alternative to the slow, weather-dependent sun drying method.

Thin-Layer Drying Kinetics

Grain dryers exhibit faster thin-layer drying kinetics compared to sun drying, significantly reducing drying time and minimizing grain quality degradation due to controlled temperature and airflow conditions. Sun drying presents variable drying rates influenced by climatic factors, often resulting in uneven moisture removal and higher exposure to contamination risks during post-harvest processing.

Moisture Gradient Management

Grain dryers provide precise control over drying temperature and airflow, effectively reducing moisture gradients within the grain bulk and minimizing kernel stress and spoilage. Sun drying, while cost-effective, often results in uneven moisture levels due to inconsistent exposure, increasing the risk of mold growth and quality degradation in post-harvest processing.

Post-harvest Microbial Deactivation

Grain dryers achieve higher post-harvest microbial deactivation by maintaining controlled temperature and humidity levels, effectively reducing mold and bacterial growth compared to sun drying. Sun drying exposes grains to fluctuating environmental conditions, increasing risks of microbial contamination and spoilage.

Solar-Assisted Batch Dryers

Solar-assisted batch dryers offer precise control over temperature and drying time, significantly reducing grain moisture content and minimizing post-harvest losses compared to traditional sun drying. These systems enhance energy efficiency by harnessing solar energy, ensuring consistent drying conditions that improve grain quality and storage life.

Energy Use Efficiency Index

Grain dryers demonstrate a significantly higher Energy Use Efficiency Index compared to traditional sun drying methods, utilizing controlled temperature and airflow to reduce energy consumption per unit of moisture removed. This efficiency translates to faster drying times and reduced post-harvest losses, making grain dryers a more sustainable option for large-scale agricultural operations.

Mycotoxin Risk Reduction

Grain dryers significantly reduce mycotoxin contamination by rapidly lowering moisture content to safe storage levels, preventing fungal growth and toxin development. Sun drying exposes grains to uneven drying and environmental contaminants, increasing the risk of mycotoxin accumulation during post-harvest processing.

Carbon-Neutral Drying Technology

Grain dryers equipped with carbon-neutral drying technologies significantly reduce greenhouse gas emissions compared to traditional sun drying by using renewable energy sources such as solar thermal or biomass fuels, ensuring efficient moisture removal with minimal environmental impact. This sustainable method enhances grain quality and storage life while promoting eco-friendly practices in post-harvest processing.

Grain dryer vs Sun drying for post-harvest processing Infographic

agridif.com

agridif.com