Flat belt drives offer simple construction and easy maintenance for farm machinery transmission but suffer from lower power transmission efficiency and slippage under heavy loads. V-belt drives provide higher friction and better grip, resulting in improved torque transmission and reduced slippage, making them more suitable for high-power agricultural equipment. The choice between flat belt and V-belt drives depends on the specific load requirements, maintenance capabilities, and operational conditions of the farm machinery.

Table of Comparison

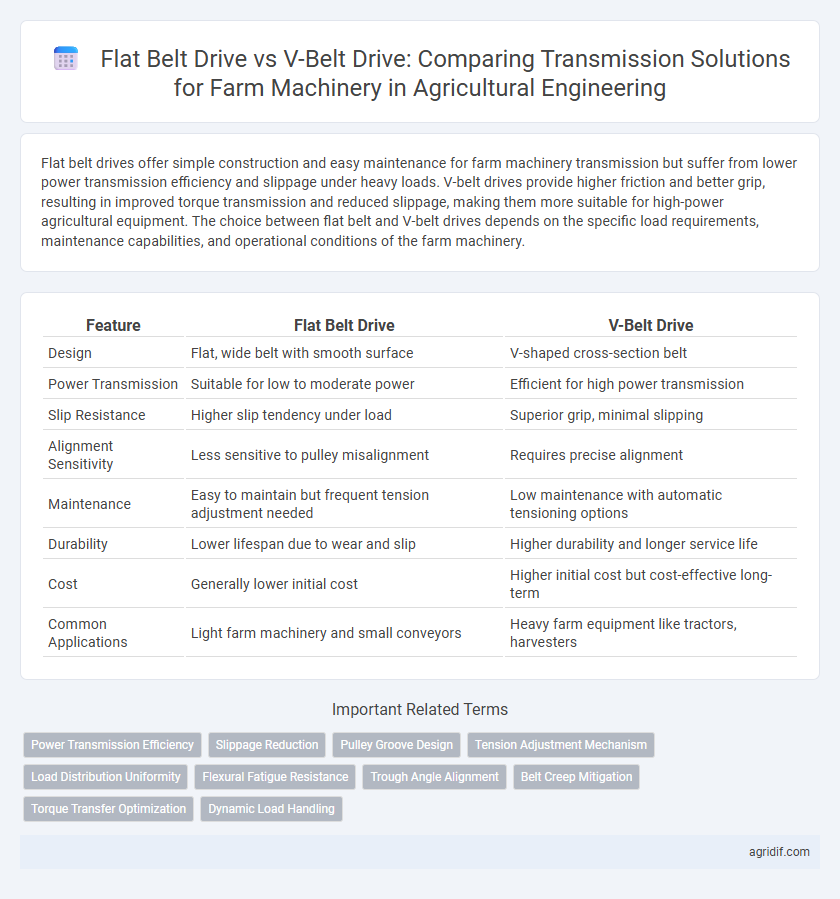

| Feature | Flat Belt Drive | V-Belt Drive |

|---|---|---|

| Design | Flat, wide belt with smooth surface | V-shaped cross-section belt |

| Power Transmission | Suitable for low to moderate power | Efficient for high power transmission |

| Slip Resistance | Higher slip tendency under load | Superior grip, minimal slipping |

| Alignment Sensitivity | Less sensitive to pulley misalignment | Requires precise alignment |

| Maintenance | Easy to maintain but frequent tension adjustment needed | Low maintenance with automatic tensioning options |

| Durability | Lower lifespan due to wear and slip | Higher durability and longer service life |

| Cost | Generally lower initial cost | Higher initial cost but cost-effective long-term |

| Common Applications | Light farm machinery and small conveyors | Heavy farm equipment like tractors, harvesters |

Introduction to Power Transmission in Farm Machinery

Flat belt drives offer simple design and easy maintenance but suffer from slippage and lower power transmission efficiency in farm machinery. V-belt drives provide higher friction, better grip, and greater power transmission capacity, making them more suitable for varying loads in agricultural equipment. Selecting between flat and V-belt drives impacts the reliability and efficiency of power transmission systems in tractors, harvesters, and irrigation pumps.

Overview of Flat Belt Drive Systems

Flat belt drive systems in agricultural machinery provide a simple, cost-effective solution for power transmission with smooth operation and low maintenance requirements. These systems use flat belts running over pulleys with wide contact surfaces, enabling efficient torque transfer and reducing slippage under moderate loads. Flat belt drives are suitable for applications where high-speed rotation and flexibility in pulley diameter adjustments are essential but may lack the compactness and higher grip performance of V-belt drives.

Overview of V-Belt Drive Systems

V-belt drive systems in agricultural machinery transmission offer improved power transmission efficiency and reduced slippage compared to flat belt drives. Their trapezoidal cross-section provides better grip and alignment, resulting in higher torque capacity and longer service life under variable farm conditions. V-belts are well-suited for transmitting power to equipment like threshers, pumps, and irrigation systems, enhancing reliability and performance.

Key Differences Between Flat Belt and V-Belt Drives

Flat belt drives offer lower friction and are suitable for high-speed, low-torque farm machinery, while V-belt drives provide higher power transmission efficiency and greater grip under heavy loads. Flat belts require larger pulleys and more maintenance due to slippage, whereas V-belts use wedge-shaped profiles that fit tightly into pulley grooves, minimizing slip and extending belt life. V-belt drives are preferred in agricultural engineering for their compact design, durability, and ability to handle variable load conditions typical in farm machinery transmission systems.

Efficiency Comparison: Flat Belt vs V-Belt

Flat belt drives typically exhibit lower efficiency, ranging from 85% to 90%, due to slippage and lower friction, making them less effective for high-torque farm machinery applications. V-belt drives offer higher efficiency levels, often between 95% and 98%, thanks to their wedging action in the pulley groove that reduces slippage and enhances power transmission. The superior efficiency of V-belt systems results in reduced energy losses and improved performance in agricultural equipment such as tractors and harvesters.

Installation and Maintenance Requirements

Flat belt drives in farm machinery require precise alignment and tensioning during installation to prevent slippage and wear, demanding regular inspection and re-tensioning for optimal performance. V-belt drives offer easier installation due to their self-centering design and maintain tension more effectively, reducing the frequency of adjustments and extending belt life. Maintenance of V-belts typically involves less downtime compared to flat belts, making them preferable for continuous agricultural operations.

Cost Analysis and Economic Considerations

Flat belt drives typically offer lower initial costs and simpler maintenance for farm machinery transmission, making them economically viable for small-scale or low-power applications. V-belt drives, despite higher upfront expenses, provide greater power transmission efficiency, reduced slippage, and longer service life, which can lower long-term operating costs in intensive agricultural operations. Cost analysis must weigh initial investment against durability and energy efficiency to determine the most cost-effective solution for specific agricultural engineering applications.

Performance in Agricultural Environments

Flat belt drives provide smooth operation and are well-suited for low-power agricultural machinery where slip is acceptable, but they are more prone to misalignment and reduced efficiency under heavy loads and dusty farm conditions. V-belt drives offer superior grip and higher transmission efficiency due to their wedging action in pulleys, making them more reliable in rugged agricultural environments with variable loads and dirt exposure. The improved power transmission and durability of V-belts enhance machinery performance, reduce maintenance, and extend service life in demanding farm applications.

Suitability for Specific Farm Machinery Applications

Flat belt drives are ideal for low-power, low-speed farm machinery such as threshers and small conveyors due to their ability to transmit power over long distances with minimal slippage. V-belt drives offer superior grip and efficiency, making them suitable for high-power, high-speed applications like tractors and combine harvesters where torque transmission and compact design are critical. The choice between flat and V-belt drives depends on the specific mechanical load, operational speed, and environmental conditions of the farm equipment.

Future Trends in Farm Machinery Power Transmission

Future trends in farm machinery power transmission emphasize the adoption of V-belt drives due to their superior power transmission efficiency, reduced slippage, and enhanced durability compared to flat belt drives. Advances in materials science are enabling the development of high-performance V-belts with increased heat resistance and tensile strength, promoting longer service life in demanding agricultural environments. Integration of smart monitoring technologies in V-belt drives facilitates predictive maintenance and optimized performance, driving improved reliability in modern farm machinery transmissions.

Related Important Terms

Power Transmission Efficiency

V-belt drives in farm machinery transmission offer higher power transmission efficiency compared to flat belt drives due to better grip and reduced slippage, which minimizes energy loss during operation. The V-shaped belt design increases frictional contact area and enables greater torque transfer, making it more suitable for high-load agricultural equipment.

Slippage Reduction

V-belt drives provide superior slippage reduction compared to flat belt drives in farm machinery transmission due to their wedge-shaped design, which increases friction and grip on the pulleys. This enhanced traction minimizes energy loss and improves the efficiency and reliability of agricultural equipment under varying load conditions.

Pulley Groove Design

Flat belt drives utilize simple, smooth pulleys that allow easy alignment but offer lower friction and slip resistance, making them less efficient for high-torque farm machinery transmission. V-belt drives feature grooved, angled pulleys that increase contact surface and friction, enhancing power transmission efficiency and reducing slippage under heavy agricultural loads.

Tension Adjustment Mechanism

Flat belt drives in farm machinery transmission use manual tension adjustment mechanisms involving idler pulleys or adjustable motor mounts, which can lead to frequent maintenance and slippage under heavy loads. V-belt drives feature automatic tensioning systems or spring-loaded tensioners, providing consistent belt tension, higher power transmission efficiency, and reduced maintenance for demanding agricultural applications.

Load Distribution Uniformity

Flat belt drives exhibit less uniform load distribution due to their larger contact surface and flexible tension, leading to uneven stress and potential slippage in farm machinery transmission. V-belt drives provide more consistent load distribution through their wedging action in the pulley groove, enhancing grip and torque transmission efficiency in agricultural equipment.

Flexural Fatigue Resistance

Flat belt drives exhibit lower flexural fatigue resistance compared to V-belt drives, as the flat belts undergo repeated bending over pulleys leading to faster wear and potential failure. V-belt drives feature a trapezoidal cross-section that reduces bending stress and enhances durability, making them more suitable for farm machinery transmission requiring high flexural fatigue resistance.

Trough Angle Alignment

V-belt drives maintain superior trough angle alignment compared to flat belt drives, ensuring efficient power transmission and reduced slippage in farm machinery. Correct trough angle alignment in V-belts minimizes belt wear and improves torque transfer, essential for reliable agricultural equipment performance.

Belt Creep Mitigation

V-belt drives inherently reduce belt creep due to their wedging action in the pulley groove, providing more positive traction compared to flat belt drives commonly used in farm machinery transmission. This enhanced grip minimizes slippage under varying agricultural load conditions, improving power transmission efficiency and extending belt and pulley lifespan.

Torque Transfer Optimization

V-belt drives in farm machinery transmission offer superior torque transfer optimization due to their increased contact surface area and wedging action in the pulley groove, reducing slip under heavy loads compared to flat belt drives. Flat belt drives, while simpler and cost-effective, experience higher slip and lower torque transmission efficiency, making V-belts preferable for optimizing power delivery in agricultural equipment.

Dynamic Load Handling

Flat belt drives offer lower friction and smoother operation but struggle with dynamic load fluctuations common in farm machinery, leading to potential slippage and reduced efficiency. V-belt drives provide superior grip and dynamic load handling due to their wedging action within pulleys, ensuring consistent power transmission under varying loads in agricultural applications.

Flat belt drive vs V-belt drive for farm machinery transmission Infographic

agridif.com

agridif.com