Mechanical weeding enhances efficiency in weed control by using specialized equipment that reduces labor intensity and covers larger areas faster than manual weeding. It provides consistent soil disturbance, which suppresses weed growth while minimizing crop damage when properly managed. Manual weeding, though labor-intensive, allows precise removal of weeds, especially in small-scale farms or areas with complex crop arrangements where machinery cannot operate effectively.

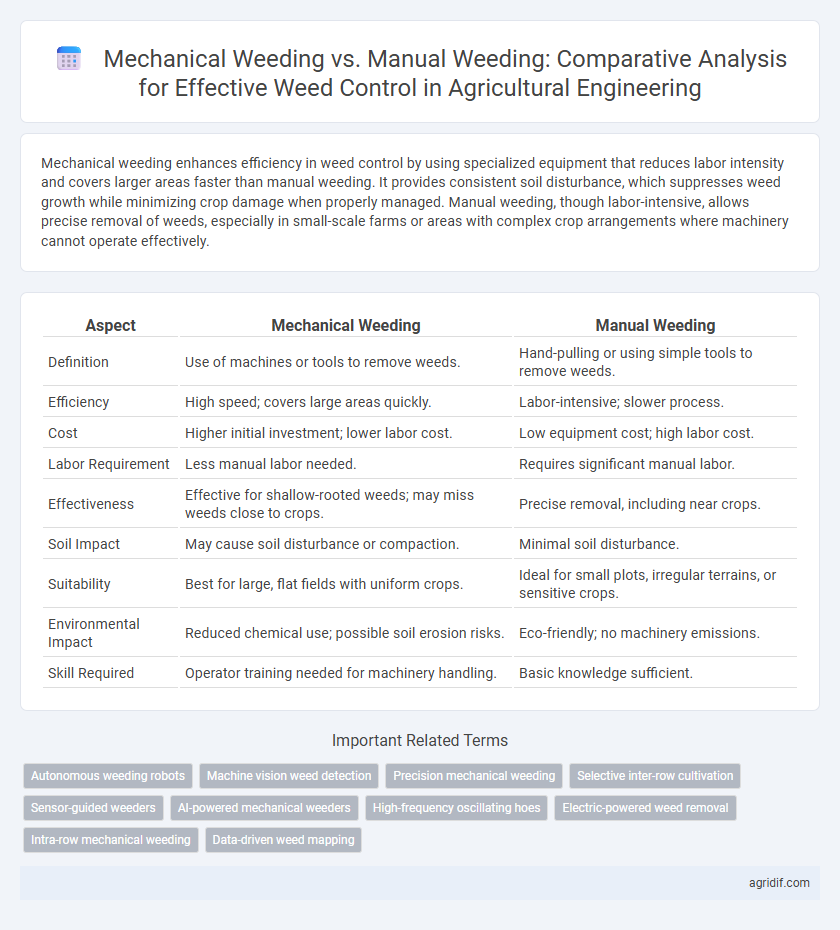

Table of Comparison

| Aspect | Mechanical Weeding | Manual Weeding |

|---|---|---|

| Definition | Use of machines or tools to remove weeds. | Hand-pulling or using simple tools to remove weeds. |

| Efficiency | High speed; covers large areas quickly. | Labor-intensive; slower process. |

| Cost | Higher initial investment; lower labor cost. | Low equipment cost; high labor cost. |

| Labor Requirement | Less manual labor needed. | Requires significant manual labor. |

| Effectiveness | Effective for shallow-rooted weeds; may miss weeds close to crops. | Precise removal, including near crops. |

| Soil Impact | May cause soil disturbance or compaction. | Minimal soil disturbance. |

| Suitability | Best for large, flat fields with uniform crops. | Ideal for small plots, irregular terrains, or sensitive crops. |

| Environmental Impact | Reduced chemical use; possible soil erosion risks. | Eco-friendly; no machinery emissions. |

| Skill Required | Operator training needed for machinery handling. | Basic knowledge sufficient. |

Introduction to Weed Control in Agriculture

Mechanical weeding employs specialized machinery such as cultivators and hoeing tools to efficiently remove weeds, reducing labor costs and soil disturbance compared to manual weeding. Manual weeding, while labor-intensive, allows for precise weed removal, especially in small-scale or delicate crop systems where machinery may cause damage. Effective weed control in agriculture relies on selecting appropriate methods based on crop type, weed species, soil conditions, and available resources to optimize productivity and sustainability.

Overview of Mechanical Weeding Technologies

Mechanical weeding technologies in agricultural engineering involve the use of automated or motorized tools such as rotary hoes, cultivators, and robotic weeders to disrupt weed growth efficiently across crop fields. These technologies increase operational speed and reduce labor costs compared to manual weeding, while also minimizing soil disturbance and crop damage through precision engineering. Innovations in sensor-based guidance systems and AI-driven weed recognition enhance the effectiveness of mechanical weeders by targeting weeds selectively, improving overall weed control management.

Manual Weeding Methods and Practices

Manual weeding methods in agricultural engineering involve hand-pulling, hoeing, and scraping to physically remove weeds from crop fields, ensuring minimal soil disturbance and protecting crop roots. These practices are highly effective for small-scale farms and gardens where precision is required to avoid crop damage. Labor intensity is the main limitation, but manual weeding remains vital for organic farming systems and areas with limited access to mechanized equipment.

Efficiency Comparison: Mechanical vs Manual Weeding

Mechanical weeding significantly increases efficiency by covering larger areas in less time compared to manual weeding, which is labor-intensive and slower. Mechanical weeders utilize advanced technologies such as rotary hoes and inter-row cultivators to target weeds precisely, reducing crop damage and improving overall productivity. Despite higher initial costs, mechanical weeding reduces labor expenses and enhances weed control consistency, making it a preferred method for large-scale agricultural operations.

Cost Analysis: Initial Investment and Operation

Mechanical weeding involves a significant initial investment in machinery, such as weeders or cultivators, which can range from $2,000 to $15,000 depending on the equipment size and technology. Operation costs for mechanical weeding are generally lower due to reduced labor demands, averaging $15 to $30 per hectare per season, while manual weeding requires minimal initial investment but incurs high labor costs often exceeding $50 per hectare. Over time, mechanical weeding provides better cost efficiency in large-scale farming by optimizing labor productivity and reducing recurring expenses.

Labor Requirements and Availability

Mechanical weeding significantly reduces labor requirements compared to manual weeding, enabling faster and more efficient weed control over large agricultural areas. Manual weeding demands extensive human labor, making it less feasible in regions with labor shortages or high labor costs. The availability of skilled operators and appropriate machinery influences the practicality of mechanical weeding, while manual weeding relies heavily on readily available manual labor.

Environmental Impact of Weeding Techniques

Mechanical weeding significantly reduces environmental damage compared to manual weeding by minimizing the reliance on chemical herbicides, which can contaminate soil and water systems. This technique preserves soil structure and biodiversity, promoting sustainable agricultural practices that enhance ecosystem health. In contrast, manual weeding, although labor-intensive, often leads to increased soil disturbance and can contribute to higher greenhouse gas emissions due to extensive human labor requirements.

Crop Yield and Quality Outcomes

Mechanical weeding significantly enhances crop yield and quality by providing consistent and timely weed removal, reducing competition for nutrients, water, and sunlight. Studies indicate mechanical methods can increase yield by up to 20% compared to manual weeding due to improved soil aeration and minimized crop damage. Mechanical weeding also supports uniform crop growth, leading to higher-quality produce with better marketability and reduced labor costs.

Suitability for Different Cropping Systems

Mechanical weeding proves highly suitable for large-scale monoculture systems, offering efficient weed control with reduced labor costs, especially in row crops like maize and wheat. Manual weeding remains essential in smallholder farms and diverse intercropping systems where precision and minimal crop disturbance are critical. Selection between mechanical and manual methods depends on crop type, field size, and labor availability, influencing overall weed management effectiveness.

Future Trends in Weed Control Mechanization

Mechanical weeding technology is rapidly advancing with the integration of robotics and AI-driven sensors to enhance precision and reduce crop damage. Autonomous weeding machines equipped with computer vision are expected to dominate future agricultural practices, increasing efficiency and sustainability by minimizing herbicide use. Research in smart implements and real-time weed recognition systems promises to transform mechanical weed control into a highly adaptive, cost-effective solution surpassing manual weeding.

Related Important Terms

Autonomous weeding robots

Autonomous weeding robots leverage advanced sensors and AI algorithms to precisely identify and remove weeds, significantly reducing labor costs and increasing efficiency compared to manual weeding. These mechanical weeding systems enhance crop yield by minimizing herbicide use and soil disturbance while enabling scalable, sustainable weed management in modern agriculture.

Machine vision weed detection

Mechanical weeding using machine vision technology enables precise identification and targeting of weeds, significantly improving efficiency compared to manual weeding by reducing labor costs and minimizing crop damage. Advanced image processing algorithms integrated into automated systems enhance real-time weed detection accuracy, leading to optimized herbicide application and sustainable weed management in agricultural fields.

Precision mechanical weeding

Precision mechanical weeding utilizes advanced sensors and GPS technology to target weeds with high accuracy, reducing crop damage and minimizing herbicide use compared to manual weeding. This method enhances efficiency in large-scale farming by optimizing labor costs and improving overall weed control effectiveness in sustainable agriculture.

Selective inter-row cultivation

Mechanical weeding through selective inter-row cultivation enhances weed control by targeting weeds specifically between crop rows, minimizing crop damage and improving soil aeration compared to manual weeding. This method increases efficiency, reduces labor costs, and supports sustainable agricultural practices by promoting soil health and reducing herbicide dependence.

Sensor-guided weeders

Sensor-guided mechanical weeders enhance precision in weed control by accurately distinguishing weeds from crops, significantly reducing labor costs and minimizing crop damage compared to manual weeding. Advances in machine vision and AI algorithms enable real-time identification and targeted removal of weeds, increasing efficiency and sustainability in agricultural weed management.

AI-powered mechanical weeders

AI-powered mechanical weeders offer precise, efficient weed control by leveraging machine learning algorithms and computer vision to identify and remove weeds selectively, significantly reducing labor costs and crop damage compared to manual weeding. These advanced systems enhance operational speed and consistency, enabling scalable weed management that improves crop yields and supports sustainable agricultural practices.

High-frequency oscillating hoes

High-frequency oscillating hoes significantly improve weed control efficiency by delivering rapid, precise soil disturbance that targets weed roots without damaging crops, reducing labor costs compared to manual weeding. This mechanical weeding method enhances soil aeration and promotes sustainable farming practices by minimizing herbicide use and supporting organic agriculture.

Electric-powered weed removal

Electric-powered mechanical weeding enhances efficiency in weed control by reducing labor intensity and increasing precision compared to manual weeding methods. This technology reduces reliance on herbicides, promotes sustainable farming practices, and improves crop yield by targeting weeds while minimizing soil disturbance.

Intra-row mechanical weeding

Intra-row mechanical weeding offers precise control of weeds within crop rows, significantly reducing labor costs and soil disturbance compared to manual weeding methods. Advanced tools like finger weeders and hood weeders target weeds close to the crop stem, enhancing crop yield and minimizing herbicide use in sustainable agricultural practices.

Data-driven weed mapping

Mechanical weeding combined with data-driven weed mapping enhances precision in targeting weed infestations, reducing crop damage and labor costs compared to manual weeding. Advanced sensors and machine learning algorithms enable real-time detection and removal of weeds, optimizing herbicide application and improving overall field management efficiency.

Mechanical weeding vs manual weeding for weed control Infographic

agridif.com

agridif.com