Flatbed dryers provide uniform airflow and temperature control, ensuring consistent moisture removal from crops with reduced drying time. Solar tunnel dryers leverage solar energy through a greenhouse-like structure, offering energy-efficient drying while protecting crops from pests and dust. Choosing between the two depends on factors like crop type, drying capacity, available space, and operational costs, with flatbed dryers often suited for higher volume and solar tunnel dryers preferred for sustainable, low-cost drying.

Table of Comparison

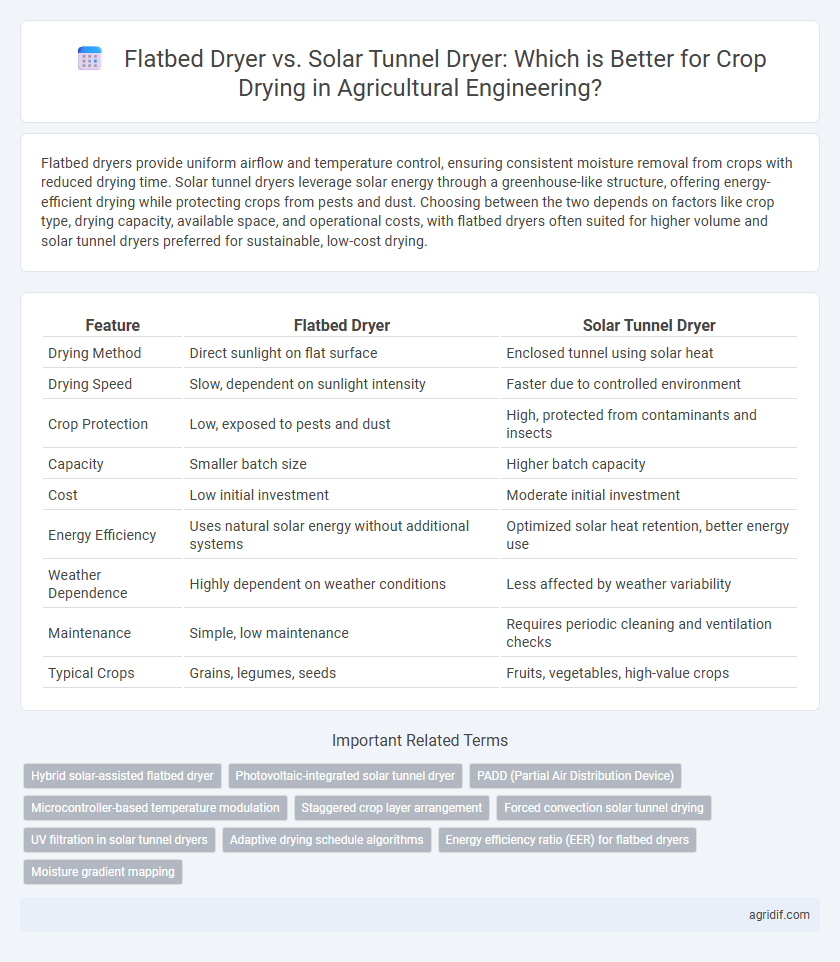

| Feature | Flatbed Dryer | Solar Tunnel Dryer |

|---|---|---|

| Drying Method | Direct sunlight on flat surface | Enclosed tunnel using solar heat |

| Drying Speed | Slow, dependent on sunlight intensity | Faster due to controlled environment |

| Crop Protection | Low, exposed to pests and dust | High, protected from contaminants and insects |

| Capacity | Smaller batch size | Higher batch capacity |

| Cost | Low initial investment | Moderate initial investment |

| Energy Efficiency | Uses natural solar energy without additional systems | Optimized solar heat retention, better energy use |

| Weather Dependence | Highly dependent on weather conditions | Less affected by weather variability |

| Maintenance | Simple, low maintenance | Requires periodic cleaning and ventilation checks |

| Typical Crops | Grains, legumes, seeds | Fruits, vegetables, high-value crops |

Introduction to Crop Drying Technologies

Flatbed dryers provide uniform drying through controlled airflow and temperature, making them suitable for various crops with moderate moisture content. Solar tunnel dryers utilize greenhouse-like structures to harness solar energy efficiently, accelerating the drying process while preserving crop quality and reducing post-harvest losses. Both technologies enhance drying efficiency by minimizing microbial growth and enzymatic activity during crop preservation.

Overview of Flatbed Dryers

Flatbed dryers are widely used in agricultural engineering for efficient crop drying, characterized by a horizontal drying platform that facilitates uniform moisture removal. These dryers operate using controlled heat and airflow, ensuring minimal nutrient loss and improved drying rates compared to traditional sun drying methods. The flatbed design supports batch processing of various crops, making it a versatile and cost-effective solution in post-harvest technology.

Overview of Solar Tunnel Dryers

Solar tunnel dryers use greenhouse technology with transparent polyethylene covers to create a controlled drying environment, significantly reducing moisture content in crops while preserving quality. These dryers offer uniform airflow and elevated temperatures, improving drying efficiency compared to flatbed dryers, which are more exposed to ambient conditions. Their design minimizes contamination and insect infestation, making them suitable for crops requiring hygienic drying processes.

Comparative Energy Efficiency

Flatbed dryers typically consume more energy due to reliance on electric or fossil fuel heaters, whereas solar tunnel dryers utilize solar energy, significantly reducing operational costs and environmental impact. The solar tunnel dryer offers higher energy efficiency by harnessing abundant solar radiation, making it ideal for regions with high sunlight exposure. Comparative studies show solar tunnel dryers can reduce energy consumption by up to 70% compared to conventional flatbed dryers, enhancing sustainable crop drying practices.

Drying Performance and Uniformity

Flatbed dryers offer moderate drying performance with controlled heat distribution but often exhibit uneven moisture removal due to static airflow patterns, potentially compromising crop quality. Solar tunnel dryers enhance drying uniformity by utilizing a greenhouse-like structure that promotes consistent airflow and temperature, accelerating moisture evaporation while protecting crops from contamination. Comparative studies show solar tunnel dryers achieve higher drying efficiency and better preservation of nutritional content, making them preferable for large-scale, quality-sensitive crop drying.

Impact on Crop Quality

Flatbed dryers provide consistent airflow and controlled temperature, minimizing nutrient loss and preserving the color and texture of crops. Solar tunnel dryers enhance drying efficiency through greenhouse-like structures, reducing contamination and improving retention of bioactive compounds. Both methods reduce drying time compared to traditional open-air drying, but solar tunnel dryers offer better protection against weather variations, resulting in higher overall crop quality.

Cost Analysis and Affordability

Flatbed dryers generally have lower initial investment costs compared to solar tunnel dryers, making them more affordable for small-scale farmers. Solar tunnel dryers, while more expensive upfront due to their structure and technology, offer better drying efficiency and reduced post-harvest losses, potentially leading to higher long-term savings. Cost analysis reveals that the choice depends on the farmer's budget and scale, with flatbed dryers favoring lower capital availability and solar tunnel dryers providing value through enhanced drying performance.

Environmental Sustainability

Flatbed dryers consume more electrical energy compared to solar tunnel dryers, leading to higher carbon emissions and environmental impact. Solar tunnel dryers harness renewable solar energy, significantly reducing fossil fuel dependence and promoting sustainable crop drying practices. Their design also minimizes heat loss and enhances drying efficiency, contributing to eco-friendly agriculture.

Suitability for Different Crops

Flatbed dryers exhibit versatility in drying diverse crops such as grains, seeds, and spices due to their uniform heat distribution and gentle drying process, minimizing quality degradation. Solar tunnel dryers are particularly suitable for high-moisture and perishable crops like fruits and vegetables, benefiting from controlled ventilation and higher drying rates that preserve nutritional value and color. The choice between flatbed and solar tunnel dryers depends on crop type, drying time, and sensitivity to temperature, influencing the post-harvest quality and shelf life.

Future Trends in Crop Drying Methods

Emerging trends in crop drying emphasize energy efficiency and sustainability, with solar tunnel dryers gaining prominence due to improved temperature control and faster drying rates compared to traditional flatbed dryers. Integration of smart sensors and IoT technology in solar tunnel dryers enables real-time monitoring and optimization of drying parameters, reducing post-harvest losses. Advancements in hybrid drying systems combining solar energy with auxiliary heating are projected to enhance reliability and scalability in diverse climatic conditions.

Related Important Terms

Hybrid solar-assisted flatbed dryer

Hybrid solar-assisted flatbed dryers optimize crop drying by combining conventional flatbed drying methods with solar energy, enhancing drying efficiency and reducing energy consumption compared to traditional solar tunnel dryers. The hybrid system maintains uniform temperature and airflow, minimizing drying time while preserving crop quality and nutrient content during post-harvest processing.

Photovoltaic-integrated solar tunnel dryer

Photovoltaic-integrated solar tunnel dryers harness solar energy more efficiently than traditional flatbed dryers by combining controlled airflow with renewable electricity, resulting in faster drying times and improved crop quality. These systems reduce dependence on fossil fuels, offer higher drying capacity, and enable continuous operation regardless of weather conditions, making them superior for sustainable agricultural crop drying.

PADD (Partial Air Distribution Device)

Flatbed dryers equipped with Partial Air Distribution Devices (PADD) offer uniform airflow and improved drying rates, enhancing moisture removal efficiency compared to solar tunnel dryers which rely on natural convection and often exhibit uneven air distribution. Incorporating PADD in flatbed dryers optimizes temperature and humidity control, reducing drying time and preserving crop quality more effectively than solar tunnel dryers.

Microcontroller-based temperature modulation

Microcontroller-based temperature modulation in flatbed dryers allows precise control of heat distribution, ensuring uniform drying and reduced moisture content in crops. In contrast, solar tunnel dryers equipped with microcontrollers optimize temperature by adjusting ventilation and solar exposure, enhancing energy efficiency while maintaining optimal crop quality.

Staggered crop layer arrangement

Flatbed dryers with staggered crop layer arrangements improve uniform drying by enhancing airflow through each layer, reducing moisture content more efficiently compared to solar tunnel dryers. Solar tunnel dryers, while energy-efficient, often have limited airflow distribution, leading to uneven drying in staggered arrangements and potential crop quality degradation.

Forced convection solar tunnel drying

Forced convection solar tunnel dryers enhance crop drying efficiency by maintaining uniform airflow and controlled temperature, significantly reducing moisture content compared to flatbed dryers that rely on natural convection. This method ensures faster drying rates, minimizes microbial contamination, and improves the quality of dried agricultural products such as grains, fruits, and spices.

UV filtration in solar tunnel dryers

Solar tunnel dryers provide enhanced UV filtration using transparent UV-resistant covers that protect crops from harmful ultraviolet rays, preserving nutrient quality and color more effectively than flatbed dryers. This UV filtration in solar tunnel dryers reduces degradation and extends shelf life, ensuring higher quality crop drying compared to traditional flatbed drying methods.

Adaptive drying schedule algorithms

Adaptive drying schedule algorithms in flatbed dryers optimize temperature and airflow for uniform moisture removal, enhancing energy efficiency and crop quality. In contrast, solar tunnel dryers utilize real-time solar radiation data within these algorithms to adjust drying parameters dynamically, maximizing solar energy use while minimizing drying time.

Energy efficiency ratio (EER) for flatbed dryers

Flatbed dryers typically exhibit a higher Energy Efficiency Ratio (EER) compared to solar tunnel dryers, as their mechanical drying systems optimize heat distribution and airflow, reducing energy consumption per unit of moisture removed. This efficiency advantage makes flatbed dryers more suitable for large-scale crop drying operations where consistent drying rates and energy savings are critical.

Moisture gradient mapping

Moisture gradient mapping in flatbed dryers reveals uniform drying due to consistent airflow and heat distribution, enhancing crop quality by minimizing moisture variance across layers. Solar tunnel dryers exhibit higher moisture gradients because of uneven solar radiation absorption and airflow, potentially leading to uneven drying and increased risk of microbial growth in shaded areas.

Flatbed dryer vs Solar tunnel dryer for crop drying Infographic

agridif.com

agridif.com