Hydraulic steering in tractors offers smoother, more responsive control with less operator effort compared to mechanical steering, making it ideal for precision tasks and extended operation. Mechanical steering systems, while simpler and more cost-effective, require greater physical input and can result in increased operator fatigue during prolonged use. Hydraulic systems also provide improved durability and easier maintenance, enhancing overall tractor performance in demanding agricultural environments.

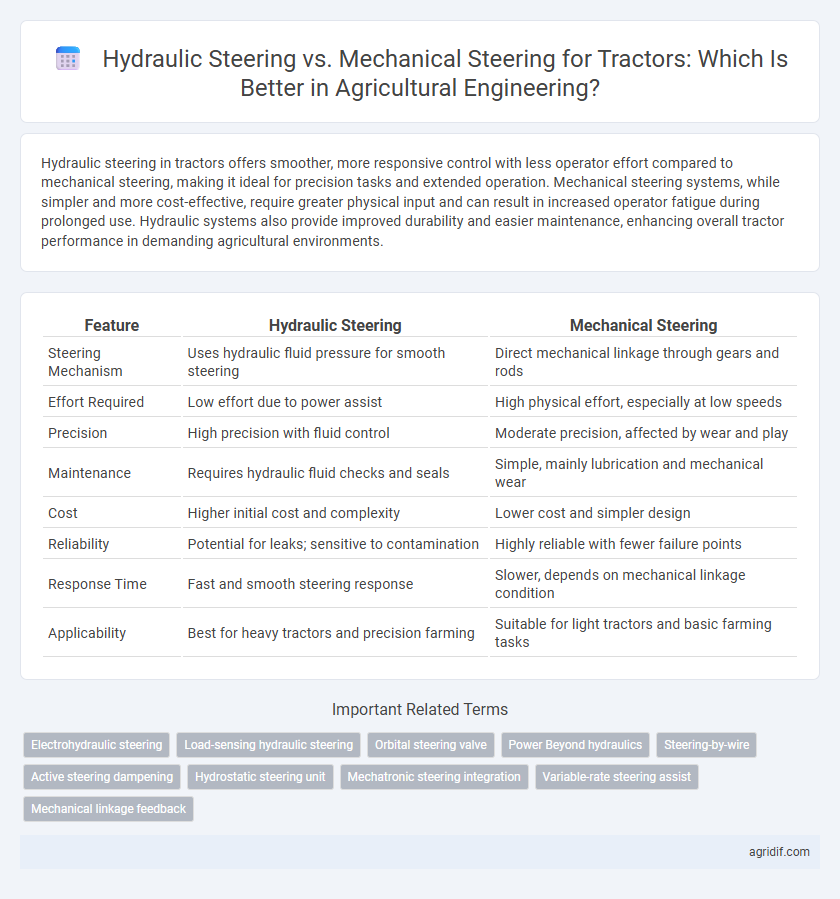

Table of Comparison

| Feature | Hydraulic Steering | Mechanical Steering |

|---|---|---|

| Steering Mechanism | Uses hydraulic fluid pressure for smooth steering | Direct mechanical linkage through gears and rods |

| Effort Required | Low effort due to power assist | High physical effort, especially at low speeds |

| Precision | High precision with fluid control | Moderate precision, affected by wear and play |

| Maintenance | Requires hydraulic fluid checks and seals | Simple, mainly lubrication and mechanical wear |

| Cost | Higher initial cost and complexity | Lower cost and simpler design |

| Reliability | Potential for leaks; sensitive to contamination | Highly reliable with fewer failure points |

| Response Time | Fast and smooth steering response | Slower, depends on mechanical linkage condition |

| Applicability | Best for heavy tractors and precision farming | Suitable for light tractors and basic farming tasks |

Introduction to Tractor Steering Systems

Hydraulic steering systems for tractors offer smoother and more precise control by using fluid pressure to assist in turning, reducing operator effort and improving maneuverability compared to mechanical steering. Mechanical steering relies on direct linkage and gears, providing a simpler, low-maintenance design but with higher steering effort and less responsiveness in challenging field conditions. Advances in agricultural engineering have increasingly favored hydraulic systems for their enhanced performance in modern tractor applications.

Overview of Hydraulic Steering in Agriculture

Hydraulic steering in agricultural tractors offers enhanced maneuverability and reduced operator fatigue by utilizing fluid pressure to control wheel movement, which is especially beneficial in large-scale farming operations. This system provides smoother and more precise steering compared to mechanical steering, allowing for better handling in varied terrain and under heavy loads. Hydraulic steering also reduces maintenance frequency due to fewer mechanical linkages, improving tractor reliability and efficiency on the field.

Mechanical Steering: Traditional Approaches Explained

Mechanical steering in tractors relies on direct linkage systems such as gears, rods, and linkages to control wheel direction, providing robust and straightforward operation. This traditional approach offers durability and ease of maintenance, making it well-suited for rugged agricultural environments where hydraulic systems might be prone to leaks or failures. Farmers often prefer mechanical steering in older or lower-cost tractor models due to its simplicity and reliability under heavy field conditions.

Comparative Efficiency: Hydraulic vs Mechanical Steering

Hydraulic steering in tractors offers superior efficiency by providing smoother, more precise control with less physical effort compared to mechanical steering systems. Mechanical steering relies on direct linkage and manual force, resulting in increased operator fatigue and slower response times during intensive fieldwork. The hydraulic system's ability to amplify steering input reduces energy consumption and enhances maneuverability, making it the preferred choice for modern agricultural machinery.

Precision and Control: Field Performance Analysis

Hydraulic steering systems in tractors provide enhanced precision and smoother control compared to mechanical steering by offering responsive adjustments through fluid power, which reduces operator fatigue during extended field operations. Field performance analysis shows that hydraulic steering improves maneuverability in tight corners and uneven terrains, enabling more accurate row alignment and reducing crop damage. Mechanical steering, while simpler and more durable, often suffers from increased play and less precise control, impacting overall efficiency and precision in agricultural tasks.

Maintenance Requirements and Longevity

Hydraulic steering systems in tractors generally require regular inspection of fluid levels and seals to prevent leaks and maintain responsive control, while mechanical steering demands frequent lubrication and adjustment of linkages to avoid wear and stiffness. Hydraulic components, although more complex, tend to offer longer service life due to smoother operation and reduced physical strain, contrasting with mechanical systems that may experience faster degradation from direct mechanical stresses. Choosing hydraulic steering often results in lower long-term maintenance effort and enhanced durability under rigorous agricultural conditions.

Cost Considerations: Initial Investment and Upkeep

Hydraulic steering systems in tractors typically incur higher initial investment costs compared to mechanical steering due to the complexity of hydraulic components and installation requirements. Maintenance expenses for hydraulic steering include regular fluid checks, hose replacements, and potential pump repairs, which can increase upkeep costs over time. In contrast, mechanical steering offers lower upfront costs and simpler maintenance with fewer components, making it more cost-effective for operations with budget constraints.

Operator Comfort and Ergonomics

Hydraulic steering in tractors significantly enhances operator comfort by reducing physical effort and providing smoother, more responsive control compared to mechanical steering systems. The ergonomic benefits include minimized vibration transmission and reduced fatigue during prolonged use, which improve overall efficiency and safety in agricultural operations. Mechanical steering, while simpler and less costly, often requires greater manual force, increasing operator strain and decreasing long-term comfort.

Suitability for Different Tractor Applications

Hydraulic steering offers superior precision and ease of control, making it ideal for large tractors used in extensive farming operations and heavy-duty fieldwork. Mechanical steering, characterized by its robustness and lower maintenance, suits smaller tractors and applications where simplicity and cost-effectiveness are prioritized. Tractor operators should match steering systems to field size, tractor weight, and maneuverability requirements to optimize performance and longevity.

Future Trends in Tractor Steering Technologies

Hydraulic steering systems in tractors offer enhanced precision and reduced operator fatigue compared to traditional mechanical steering, driving widespread adoption in modern agricultural machinery. Future trends emphasize integrating advanced sensors and electronic controls with hydraulic systems to enable autonomous and semi-autonomous steering capabilities. Innovations in electro-hydraulic steering technologies aim to improve energy efficiency, responsiveness, and compatibility with GPS-guided precision farming methods.

Related Important Terms

Electrohydraulic steering

Electrohydraulic steering in tractors combines the precision of hydraulic systems with electronic control, offering improved responsiveness and reduced operator fatigue compared to purely mechanical steering. This technology enhances maneuverability in tight field conditions and optimizes hydraulic power usage, leading to better fuel efficiency and reduced wear on steering components.

Load-sensing hydraulic steering

Load-sensing hydraulic steering in tractors offers precise control with reduced operator effort by automatically adjusting the hydraulic flow based on the load, enhancing maneuverability and reducing fuel consumption compared to mechanical steering systems. Unlike mechanical steering, which relies on direct linkages, load-sensing hydraulic systems improve responsiveness under varying field conditions, minimizing wear on components and increasing overall system durability.

Orbital steering valve

Hydraulic steering with an orbital steering valve offers precise control and reduced operator effort compared to mechanical steering by using pressurized fluid to actuate the steering mechanism smoothly. The orbital steering valve's compact design enhances responsiveness and durability, making it ideal for modern tractors requiring efficient maneuverability in diverse agricultural tasks.

Power Beyond hydraulics

Hydraulic steering systems in tractors, especially those utilizing Power Beyond hydraulics, offer superior responsiveness and reduced operator fatigue compared to traditional mechanical steering by delivering consistent hydraulic pressure directly to the steering components. Mechanical steering relies on physical linkages that can wear over time, leading to less precise control and increased maintenance, whereas Power Beyond hydraulics enable seamless integration with auxiliary hydraulic functions for enhanced operational efficiency.

Steering-by-wire

Hydraulic steering in tractors offers smooth, responsive control with high power assistance, enhancing maneuverability in heavy-duty agricultural tasks, while mechanical steering provides direct, robust feedback and simple maintenance without hydraulic fluid reliance. Steering-by-wire technology eliminates mechanical linkages entirely, enabling precise electronic control, customizable steering settings, and improved safety features, marking a significant advancement over both traditional hydraulic and mechanical systems in modern agricultural engineering.

Active steering dampening

Hydraulic steering systems in tractors provide superior active steering dampening by using fluid pressure to absorb shocks and vibrations, resulting in smoother control and reduced operator fatigue compared to mechanical steering. Mechanical steering relies on direct linkages and lacks the dynamic vibration absorption capabilities essential for precise maneuverability in rough agricultural terrains.

Hydrostatic steering unit

Hydrostatic steering units provide precise control and reduced operator effort compared to traditional mechanical steering systems in tractors, enhancing maneuverability in agricultural operations. Their integration with hydraulic systems allows seamless power transmission and durability under heavy loads, optimizing efficiency and reducing maintenance requirements.

Mechatronic steering integration

Hydraulic steering systems in tractors offer smooth, responsive control through fluid power, enhancing maneuverability in demanding agricultural tasks, while mechanical steering provides durability with direct linkages requiring more physical effort. Mechatronic steering integration combines hydraulic actuation with electronic control units and sensors, enabling precise, adaptive steering performance that reduces operator fatigue and improves efficiency in precision agriculture.

Variable-rate steering assist

Hydraulic steering in tractors offers variable-rate steering assist, providing smoother and more precise control with reduced operator effort compared to mechanical steering systems that rely on fixed, direct linkage. This advanced hydraulic technology enhances maneuverability and efficiency in field operations, adapting steering response to varying speeds and terrain conditions.

Mechanical linkage feedback

Mechanical steering in tractors utilizes a direct linkage system that provides precise tactile feedback to the operator, enhancing control by allowing them to feel the resistance and terrain through the steering wheel. This feedback is crucial for maneuvering in varied agricultural environments, as it enables better response to soil conditions and obstacles compared to the less responsive hydraulic steering systems.

Hydraulic steering vs Mechanical steering for tractors Infographic

agridif.com

agridif.com