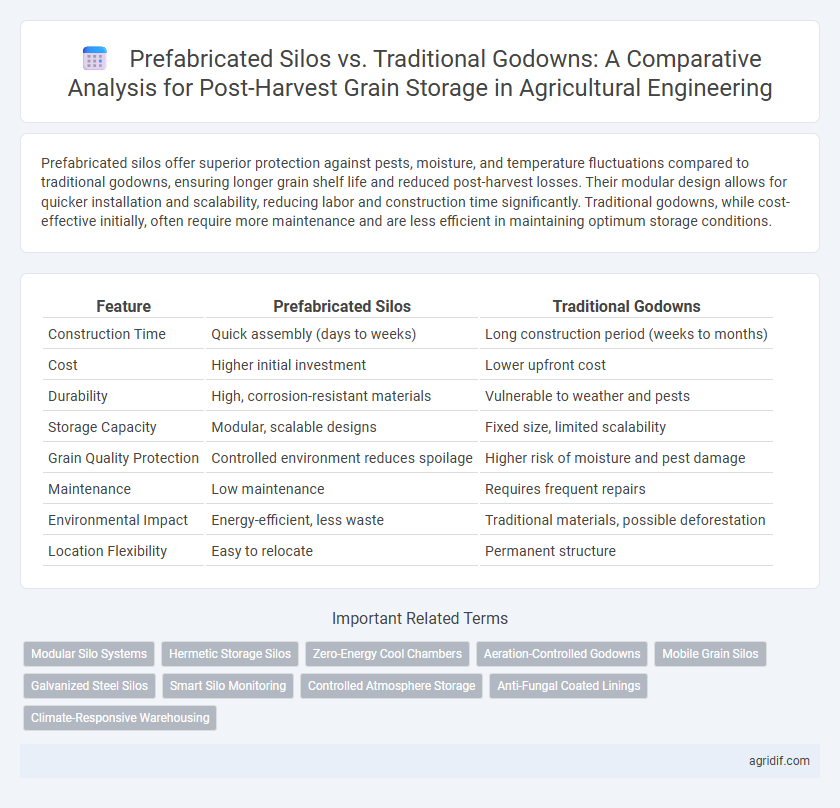

Prefabricated silos offer superior protection against pests, moisture, and temperature fluctuations compared to traditional godowns, ensuring longer grain shelf life and reduced post-harvest losses. Their modular design allows for quicker installation and scalability, reducing labor and construction time significantly. Traditional godowns, while cost-effective initially, often require more maintenance and are less efficient in maintaining optimum storage conditions.

Table of Comparison

| Feature | Prefabricated Silos | Traditional Godowns |

|---|---|---|

| Construction Time | Quick assembly (days to weeks) | Long construction period (weeks to months) |

| Cost | Higher initial investment | Lower upfront cost |

| Durability | High, corrosion-resistant materials | Vulnerable to weather and pests |

| Storage Capacity | Modular, scalable designs | Fixed size, limited scalability |

| Grain Quality Protection | Controlled environment reduces spoilage | Higher risk of moisture and pest damage |

| Maintenance | Low maintenance | Requires frequent repairs |

| Environmental Impact | Energy-efficient, less waste | Traditional materials, possible deforestation |

| Location Flexibility | Easy to relocate | Permanent structure |

Introduction to Post-Harvest Grain Storage Methods

Post-harvest grain storage methods include prefabricated silos and traditional godowns, each offering distinct advantages for maintaining grain quality and reducing losses. Prefabricated silos provide airtight, durable environments that minimize pest infestation and moisture ingress, enhancing long-term storage efficacy. Traditional godowns, often constructed with local materials, offer flexibility and cost-effectiveness but may require regular maintenance to prevent spoilage and infestation.

Overview of Prefabricated Silos in Modern Agriculture

Prefabricated silos offer modern agriculture efficient post-harvest grain storage by enhancing protection against pests, moisture, and fungal contamination, thereby reducing grain loss significantly. These silos are constructed using durable materials such as galvanized steel or aluminum, allowing for rapid assembly and scalability compared to traditional godowns. Advanced features like airtight sealing and integrated aeration systems ensure sustained grain quality and optimized storage conditions throughout extended periods.

Traditional Godowns: Design and Functionality

Traditional godowns are typically constructed using locally sourced materials such as bricks, clay, or timber, designed with thick walls and elevated floors to prevent moisture ingress and pest infestation. Their functionality emphasizes natural ventilation through strategically placed vents or windows, ensuring reduced humidity and temperature control to prolong grain freshness. The structural design often includes sloped roofs for rainwater runoff, enhancing grain protection during the monsoon season and minimizing post-harvest losses.

Comparative Analysis: Storage Capacity and Space Utilization

Prefabricated silos offer superior storage capacity with vertical design, maximizing space utilization on smaller footprints compared to traditional godowns that require extensive floor area. Silos provide airtight conditions that enhance grain preservation, reducing post-harvest losses more effectively than godowns, which often suffer from moisture and pest issues due to suboptimal sealing. The modular nature of prefabricated silos allows easy scalability and efficient stacking, optimizing land use and operational management in grain storage facilities.

Impact on Grain Quality and Loss Prevention

Prefabricated silos offer superior protection against moisture, pests, and temperature fluctuations, significantly reducing grain spoilage and insect infestation compared to traditional godowns. Their airtight design minimizes fungal growth and mycotoxin contamination, ensuring higher grain quality during extended storage periods. Traditional godowns often suffer from poor ventilation and structural vulnerabilities, leading to increased grain loss and compromised post-harvest preservation.

Construction Time and Cost Efficiency

Prefabricated silos significantly reduce construction time compared to traditional godowns, often requiring only a few weeks versus several months. The modular design and off-site manufacturing of prefabricated silos enhance cost efficiency by minimizing labor and material wastage. These advantages make prefabricated silos a preferred choice for rapid deployment and budget-conscious post-harvest grain storage solutions.

Maintenance, Durability, and Lifespan

Prefabricated silos offer superior durability and longer lifespan compared to traditional godowns due to their corrosion-resistant materials and precision engineering. Maintenance requirements for prefabricated silos are significantly lower, as they are designed with modular components that facilitate easy cleaning and prompt repair. In contrast, traditional godowns require frequent structural inspections and repairs to prevent pest infestation and moisture damage, often resulting in higher overall maintenance costs.

Adaptability to Different Climatic Conditions

Prefabricated silos offer superior adaptability to diverse climatic conditions due to their airtight design and corrosion-resistant materials, ensuring consistent grain quality by minimizing moisture ingress and pest infestation. Traditional godowns, typically constructed from brick or wood, are more susceptible to environmental variations such as humidity and temperature fluctuations, which can compromise grain safety. Advanced ventilation systems and modular construction in prefabricated silos further enhance their performance across varying climates compared to conventional storage solutions.

Technological Integration and Automation Potential

Prefabricated silos offer advanced technological integration with automated temperature and humidity controls, real-time moisture monitoring, and pest management systems that enhance grain preservation efficiency. Traditional godowns largely rely on manual inspection and limited technological adoption, leading to higher risks of grain spoilage and labor-intensive maintenance. Automation potential in prefabricated silos significantly reduces post-harvest losses by ensuring optimal storage conditions through smart sensors and IoT connectivity.

Sustainability and Environmental Considerations

Prefabricated silos offer enhanced sustainability through their modular design, which reduces material waste and allows for efficient resource use compared to traditional godowns. These silos provide superior protection against moisture and pests, minimizing grain spoilage and lowering the need for chemical preservatives, thereby reducing environmental impact. Moreover, prefabricated silos support better temperature and humidity control, contributing to longer grain shelf life and decreased carbon footprint during storage.

Related Important Terms

Modular Silo Systems

Modular silo systems offer scalable, airtight storage solutions that significantly reduce post-harvest grain losses compared to traditional godowns by providing better pest control and moisture regulation. Their prefabricated design ensures rapid installation, improved space utilization, and enhanced durability, making them ideal for modern agricultural storage needs.

Hermetic Storage Silos

Hermetic storage silos provide superior protection against pests, moisture, and fungal growth compared to traditional godowns, ensuring longer grain shelf life and reduced post-harvest losses. Their airtight design creates an oxygen-deficient environment that naturally preserves grain quality without chemical fumigants, enhancing food security and storage efficiency in agricultural engineering.

Zero-Energy Cool Chambers

Prefabricated silos offer superior protection against pests and moisture with controlled aeration systems, enhancing grain preservation compared to traditional godowns prone to higher spoilage rates; Zero-Energy Cool Chambers utilize evaporative cooling techniques to maintain optimal low temperatures without electricity, significantly reducing post-harvest losses by prolonging grain shelf life in hot climates. Integrating Zero-Energy Cool Chambers within prefabricated silos maximizes energy efficiency and grain quality, presenting an eco-friendly alternative to conventional storage that lacks temperature regulation and exposes grains to environmental risks.

Aeration-Controlled Godowns

Prefabricated silos offer superior aeration-controlled environments compared to traditional godowns, ensuring optimal temperature and humidity regulation to minimize grain spoilage and pest infestation. Advanced ventilation systems in these silos enhance post-harvest grain preservation by maintaining consistent airflow, which significantly reduces moisture accumulation and fungal growth.

Mobile Grain Silos

Mobile grain silos offer enhanced flexibility and rapid deployment compared to traditional godowns, enabling on-site storage that reduces post-harvest losses and preserves grain quality. Prefabricated silos integrate advanced aeration and moisture control technologies, optimizing storage conditions and facilitating efficient transport, which traditional godowns lack.

Galvanized Steel Silos

Galvanized steel prefabricated silos offer enhanced durability, corrosion resistance, and ease of assembly compared to traditional godowns, significantly reducing post-harvest grain spoilage and losses. Their airtight design and pest-proof structure ensure optimal grain preservation, improving storage efficiency and extending shelf life in agricultural storage systems.

Smart Silo Monitoring

Prefabricated silos equipped with smart silo monitoring systems utilize IoT sensors to provide real-time data on temperature, humidity, and grain condition, significantly reducing post-harvest losses. Traditional godowns lack such advanced monitoring capabilities, leading to increased risks of spoilage and pest infestation in grain storage.

Controlled Atmosphere Storage

Prefabricated silos equipped with Controlled Atmosphere Storage (CAS) technology offer enhanced preservation of grain quality by regulating oxygen, carbon dioxide, and humidity levels, significantly reducing post-harvest losses compared to traditional godowns. Traditional godowns lack precise atmospheric control, making them more susceptible to pest infestations, mold growth, and moisture fluctuations that compromise grain longevity.

Anti-Fungal Coated Linings

Prefabricated silos with anti-fungal coated linings significantly reduce moisture retention and inhibit mold growth, enhancing grain preservation compared to traditional godowns. These coatings improve storage hygiene and extend shelf life by providing a controlled environment that minimizes fungal contamination risks in post-harvest grain storage.

Climate-Responsive Warehousing

Prefabricated silos offer superior climate-responsive warehousing by providing airtight, moisture-controlled environments that significantly reduce post-harvest grain losses compared to traditional godowns, which often lack adequate ventilation and temperature regulation. Advanced materials and design in prefabricated silos enhance thermal insulation and pest resistance, ensuring optimal grain preservation across varying climatic conditions.

Prefabricated silos vs Traditional godowns for post-harvest grain storage Infographic

agridif.com

agridif.com