PTO-driven implements offer direct mechanical power transmission from the tractor's engine, ensuring high efficiency and reliability in field operations. Hydraulic-driven implements provide greater flexibility in speed control and ease of operation, allowing for precise adjustments and smoother performance. Selecting between PTO-driven and hydraulic-driven systems depends on the specific agricultural task, power requirements, and desired control over implement functions.

Table of Comparison

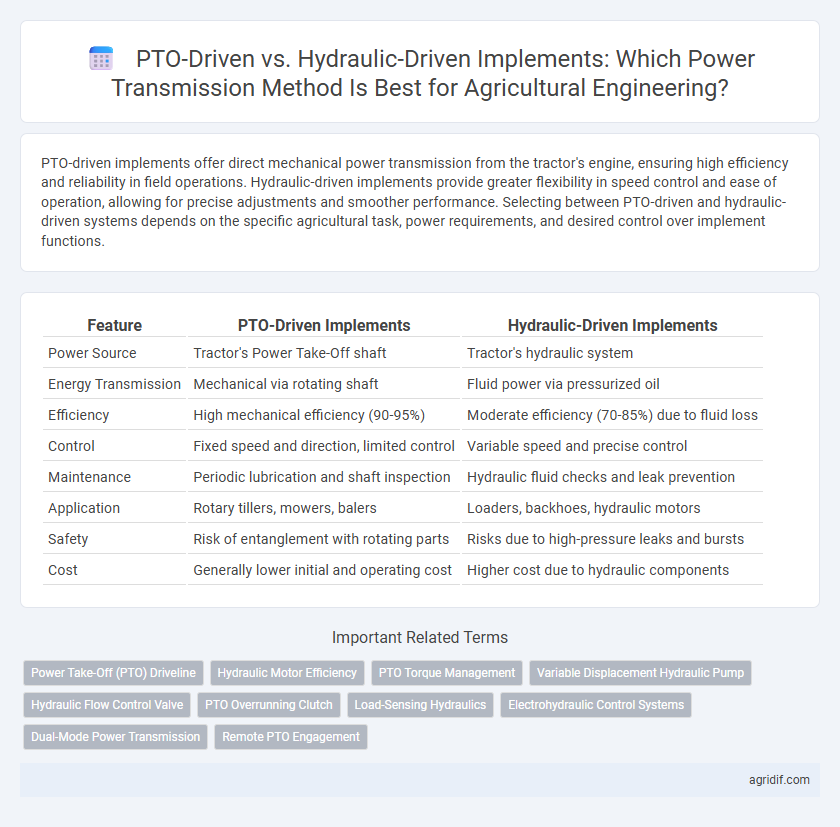

| Feature | PTO-Driven Implements | Hydraulic-Driven Implements |

|---|---|---|

| Power Source | Tractor's Power Take-Off shaft | Tractor's hydraulic system |

| Energy Transmission | Mechanical via rotating shaft | Fluid power via pressurized oil |

| Efficiency | High mechanical efficiency (90-95%) | Moderate efficiency (70-85%) due to fluid loss |

| Control | Fixed speed and direction, limited control | Variable speed and precise control |

| Maintenance | Periodic lubrication and shaft inspection | Hydraulic fluid checks and leak prevention |

| Application | Rotary tillers, mowers, balers | Loaders, backhoes, hydraulic motors |

| Safety | Risk of entanglement with rotating parts | Risks due to high-pressure leaks and bursts |

| Cost | Generally lower initial and operating cost | Higher cost due to hydraulic components |

Introduction to Power Transmission in Agricultural Implements

PTO-driven implements transfer power directly from the tractor's power take-off shaft, offering efficient and consistent energy delivery for various agricultural tasks. Hydraulic-driven implements utilize pressurized fluid to transmit power, providing greater flexibility and control, especially in variable load conditions. Choosing between PTO and hydraulic systems depends on factors such as implement type, required precision, and ease of maintenance in agricultural operations.

Overview of PTO-Driven Implement Systems

PTO-driven implement systems transmit power directly from the tractor's engine through a rotating shaft, enabling efficient energy transfer for various agricultural tasks such as mowing, baling, and tilling. These systems rely on standardized shaft speeds, typically 540 or 1000 RPM, ensuring compatibility across multiple implements and reducing power losses compared to hydraulic alternatives. The mechanical simplicity and robustness of PTO-driven systems often result in lower maintenance costs and higher reliability in field operations.

Fundamentals of Hydraulic-Driven Implements

Hydraulic-driven implements in agricultural engineering utilize fluid power to transmit energy efficiently from the tractor to the equipment, enabling precise control over speed and force. These systems rely on pressurized hydraulic fluid within cylinders and motors, offering smoother operation and reduced mechanical wear compared to PTO-driven implements. The fundamental advantage lies in their ability to provide variable torque and power delivery, enhancing implement performance in varied field conditions.

Efficiency Comparison: PTO vs Hydraulic Drives

PTO-driven implements offer higher mechanical efficiency with typical transmission losses below 10%, ensuring direct power transfer from the tractor to the implement for tasks requiring consistent rotational speed. Hydraulic-driven implements exhibit lower efficiency due to energy losses from fluid friction and heat dissipation, with overall efficiency ranging between 60% and 85%. The choice between PTO and hydraulic drives depends on specific agricultural applications, where PTO systems excel in energy conservation and hydraulic drives provide greater versatility and control.

Power Output and Torque Characteristics

PTO-driven implements typically provide a consistent power output with high rotational speed, making them ideal for tasks requiring steady torque and precise power delivery. Hydraulic-driven implements offer variable torque and power output, enabling better performance in applications demanding adjustable force and smooth operation under varying load conditions. The choice between PTO and hydraulic systems depends on balancing required torque characteristics with application-specific power demands in agricultural machinery.

Maintenance and Reliability Considerations

PTO-driven implements typically require less frequent maintenance due to their direct mechanical power transmission, reducing points of failure and enhancing overall reliability in field operations. Hydraulic-driven implements demand regular inspection of fluid levels, seals, and hoses to prevent leaks and maintain optimal pressure, which is crucial for consistent performance and durability. Selecting PTO or hydraulic systems depends on balancing maintenance ease with the operational reliability requirements specific to various agricultural tasks.

Compatibility with Modern Agricultural Machinery

PTO-driven implements offer broad compatibility with a wide range of modern tractors equipped with standardized power take-off shafts, facilitating easy attachment and efficient power transmission. Hydraulic-driven implements excel in integration with advanced machinery featuring sophisticated hydraulic systems, enabling precise control and variable power delivery tailored to complex tasks. Choosing between PTO and hydraulic-driven systems depends on matching implement specifications with tractor capabilities to maximize operational efficiency and equipment longevity.

Cost-Benefit Analysis for Farmers

PTO-driven implements typically offer a lower initial investment and reduced maintenance costs compared to hydraulic-driven systems, making them more cost-effective for small to medium-sized farms. Hydraulic-driven implements provide greater versatility and precision, enhancing operational efficiency and potentially increasing crop yields, which can justify higher upfront and maintenance expenses for larger-scale farming operations. Farmers should assess their specific crop requirements, farm size, and long-term productivity goals to determine the optimal balance between cost and performance in power transmission systems.

Safety Aspects of PTO and Hydraulic Systems

PTO-driven implements pose higher safety risks due to exposed rotating shafts that can cause severe entanglement injuries, requiring protective guards and strict operational protocols. Hydraulic-driven systems offer improved safety by using enclosed fluid power transfer, reducing direct contact with moving parts and minimizing the risk of mechanical entanglement. Regular maintenance and inspection of both PTO and hydraulic components are essential to prevent leaks, pressure bursts, and equipment failure that can lead to accidents.

Application Scenarios and Suitability in Agriculture

PTO-driven implements are ideal for applications requiring consistent rotational power, such as rotary tillers and mowers, offering direct mechanical efficiency in medium to large-scale farming operations. Hydraulic-driven implements provide greater flexibility and precision control, making them suitable for tasks like loader arms, sprayers, and variable-control equipment in both small and diversified farms. The choice depends on the specific agricultural scenario, with PTO systems favored for high-torque continuous operations, while hydraulic systems excel in multifunctional and adjustable tasks.

Related Important Terms

Power Take-Off (PTO) Driveline

Power Take-Off (PTO) drivelines deliver mechanical power from tractors to agricultural implements through a rotating shaft, offering efficient and consistent energy transfer with minimal power loss compared to hydraulic systems. PTO-driven implements provide precise speed control and higher torque transmission, making them ideal for tasks requiring steady rotational power such as mowing, baling, and tilling.

Hydraulic Motor Efficiency

Hydraulic-driven implements exhibit varying hydraulic motor efficiency rates, typically ranging from 80% to 95%, compared to the nearly constant mechanical efficiency of PTO-driven systems, which often exceeds 95%. The energy losses in hydraulic motors primarily stem from fluid friction and leakage, impacting overall power transmission efficiency in agricultural machinery.

PTO Torque Management

PTO-driven implements offer precise torque management through mechanical linkage, ensuring consistent power transfer directly from the tractor's engine RPM, which is essential for operations requiring steady rotational force. Hydraulic-driven systems provide adjustable torque via fluid pressure control, enhancing flexibility and smoothness in power delivery but may introduce lag and energy loss compared to the direct torque feedback of PTO-driven implements.

Variable Displacement Hydraulic Pump

Variable displacement hydraulic pumps in PTO-driven implements optimize power transmission by adjusting flow rate and pressure based on operational demand, enhancing fuel efficiency and reducing wear. These pumps provide precise control over implement speed and torque compared to fixed displacement systems, making hydraulic-driven setups more versatile and energy-efficient for complex agricultural tasks.

Hydraulic Flow Control Valve

Hydraulic flow control valves in agricultural implements regulate fluid flow to optimize power transmission efficiency, enabling precise control of hydraulic-driven systems compared to PTO-driven mechanisms that rely on fixed rotational speeds. These valves enhance implement performance by adjusting hydraulic pressure and flow dynamically, reducing energy losses and improving responsiveness during field operations.

PTO Overrunning Clutch

PTO-driven implements utilize a power take-off shaft for efficient mechanical power transmission, often incorporating a PTO overrunning clutch to prevent reverse torque and protect the tractor drivetrain during sudden load changes. Hydraulic-driven implements rely on fluid power, offering smoother operation but typically lack an overrunning clutch, making PTO-driven systems with overrunning clutches more effective in reducing wear and enhancing safety in variable load conditions.

Load-Sensing Hydraulics

Load-sensing hydraulics in agricultural implements optimize power transmission by adjusting flow and pressure based on demand, enhancing fuel efficiency compared to PTO-driven systems that operate at constant speeds regardless of load. This technology reduces energy waste and improves implement responsiveness, making hydraulic-driven systems superior for variable load conditions in modern farming operations.

Electrohydraulic Control Systems

Electrohydraulic control systems in agricultural implements enhance precision and responsiveness by integrating electronic sensors with hydraulic power transmission, outperforming traditional PTO-driven systems in energy efficiency and adjustable force delivery. These systems enable real-time adjustments of hydraulic actuators, improving implement control, reducing mechanical wear, and optimizing fuel consumption compared to conventional PTO shafts.

Dual-Mode Power Transmission

Dual-mode power transmission integrates PTO-driven and hydraulic-driven implements to optimize agricultural machinery efficiency by combining the direct mechanical power of PTO systems with the flexible control and torque variability of hydraulic systems. This hybrid approach enhances operational versatility, allowing seamless switching between high power output for heavy-duty tasks and precise hydraulic control for delicate implement functions, thereby improving overall field performance and reducing energy losses.

Remote PTO Engagement

Remote PTO engagement enables seamless activation of PTO-driven implements without the operator leaving the tractor cab, enhancing safety and efficiency during field operations. Hydraulic-driven implements rely on fluid power for transmission but often lack the convenience and immediate control afforded by remote PTO systems, making PTO-driven setups preferable for applications demanding precise and rapid power engagement.

PTO-driven vs Hydraulic-driven implements for power transmission Infographic

agridif.com

agridif.com