Tractor-mounted planters significantly increase planting efficiency and precision compared to manual planting for row crops by ensuring uniform seed spacing and depth. This mechanized approach reduces labor costs and time, allowing for larger acreage to be planted quickly with consistent crop stands. Enhanced seed placement optimizes germination rates and crop yield potential, making tractor-mounted planters a vital tool in modern agricultural engineering.

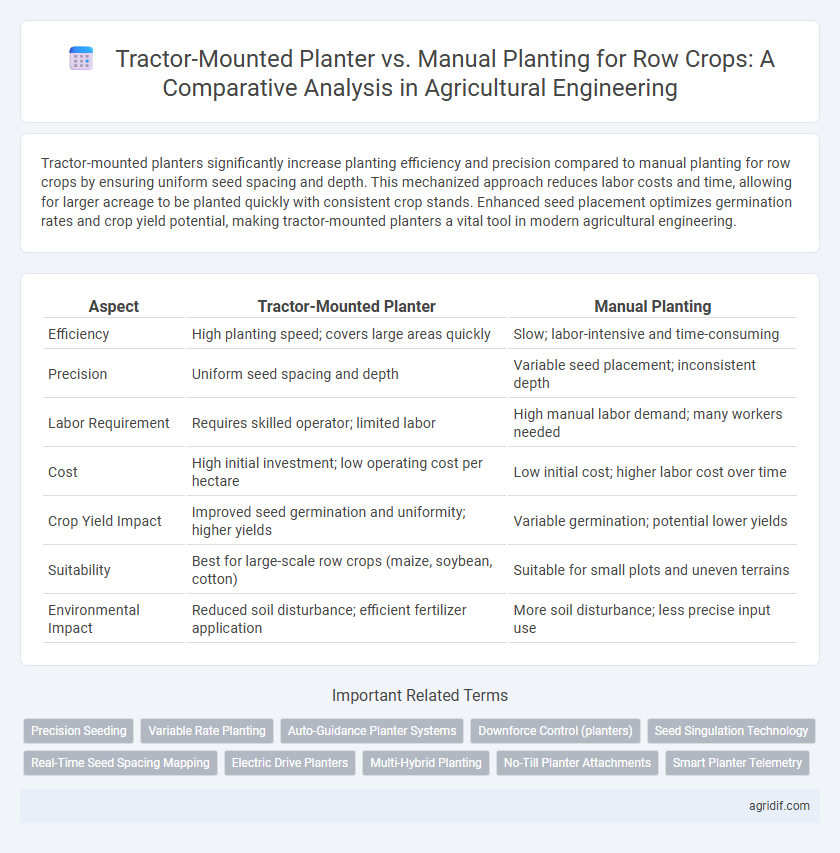

Table of Comparison

| Aspect | Tractor-Mounted Planter | Manual Planting |

|---|---|---|

| Efficiency | High planting speed; covers large areas quickly | Slow; labor-intensive and time-consuming |

| Precision | Uniform seed spacing and depth | Variable seed placement; inconsistent depth |

| Labor Requirement | Requires skilled operator; limited labor | High manual labor demand; many workers needed |

| Cost | High initial investment; low operating cost per hectare | Low initial cost; higher labor cost over time |

| Crop Yield Impact | Improved seed germination and uniformity; higher yields | Variable germination; potential lower yields |

| Suitability | Best for large-scale row crops (maize, soybean, cotton) | Suitable for small plots and uneven terrains |

| Environmental Impact | Reduced soil disturbance; efficient fertilizer application | More soil disturbance; less precise input use |

Introduction to Row Crop Planting Methods

Tractor-mounted planters offer precise seed spacing and depth control, resulting in uniform crop emergence and higher yield potential compared to manual planting. Manual planting, while labor-intensive, allows for flexibility in small or irregular fields but often lacks consistency in seed placement. Advanced row crop planting methods leverage mechanization to improve efficiency, reduce labor costs, and optimize resource use in large-scale farming operations.

Overview of Tractor-Mounted Planters

Tractor-mounted planters significantly increase planting efficiency for row crops by enabling precise seed placement and consistent row spacing at higher speeds compared to manual planting. These machines integrate seed metering systems and adjustable row units, optimizing seed depth and reducing seed wastage while enhancing overall crop uniformity. Their mechanization reduces labor costs and physical strain, supporting large-scale agricultural production with improved accuracy and faster planting operations.

Manual Planting Techniques Explained

Manual planting techniques for row crops involve precise seed placement by hand or with simple tools, enhancing control over seed depth and spacing to optimize germination rates. These methods allow farmers to adapt planting patterns to field variability and specific crop needs, which can improve yield quality despite being labor-intensive. Manual planting is particularly suitable for small-scale farms or areas with uneven terrain where tractor-mounted planters are less effective or feasible.

Efficiency Comparison: Tractor-Mounted vs Manual Planting

Tractor-mounted planters significantly enhance planting efficiency by enabling faster seed placement and uniform row spacing, reducing labor time by up to 70% compared to manual planting. Precision in seed depth and spacing improves crop germination rates and yield consistency, which manual methods often lack due to human error and fatigue. Operational scalability and reduced physical strain make tractor-mounted planters the preferred choice for large-scale row crop production.

Labor Requirements and Workforce Dynamics

Tractor-mounted planters significantly reduce labor requirements by automating seed placement, enabling a single operator to plant multiple rows simultaneously, which boosts efficiency and reduces physical strain on the workforce. Manual planting demands a larger labor force to maintain planting speed and accuracy, often resulting in higher labor costs and increased fatigue among workers. The shift to mechanized planting dynamics streamlines operations, allowing agricultural enterprises to allocate labor resources toward other critical farm tasks.

Precision and Uniformity in Seed Placement

Tractor-mounted planters offer superior precision and uniformity in seed placement compared to manual planting, ensuring consistent seed spacing and depth critical for optimal germination and crop yield. These machines utilize advanced calibration mechanisms and GPS technology to maintain exact intervals and alignments across extensive row crops, minimizing seed wastage and uneven plant growth. Manual planting, prone to human error and variability, often results in inconsistent seed distribution that can negatively impact overall crop performance and field efficiency.

Impact on Crop Yield and Productivity

Tractor-mounted planters enhance crop yield and productivity by ensuring uniform seed spacing and depth, which promotes optimal germination and growth. Compared to manual planting, mechanized planters reduce labor intensity and planting time, allowing for timely sowing and increased field efficiency. This precision in planting directly contributes to higher crop uniformity and better resource utilization, maximizing overall productivity.

Cost Analysis: Initial Investment and Operating Expenses

Tractor-mounted planters for row crops require a significantly higher initial investment, often ranging from $5,000 to $15,000, compared to minimal upfront costs associated with manual planting. Operating expenses for tractor-mounted systems include fuel, maintenance, and labor for equipment operation, which can total several hundred dollars per acre, while manual planting relies primarily on labor costs that vary by region but generally amount to higher per-acre expenses due to longer planting times. Over multiple planting seasons, tractor-mounted planters often reduce overall costs through increased efficiency and higher planting speed, making them more cost-effective for large-scale farming operations.

Environmental and Soil Health Considerations

Tractor-mounted planters enhance soil health by ensuring uniform seed placement, reducing soil compaction, and minimizing disturbance compared to manual planting. Precise planting depth and spacing optimize germination rates and promote better root development, which supports sustainable crop growth. Manual planting often leads to uneven seed distribution and increased soil disruption, negatively impacting soil structure and increasing erosion risk.

Choosing the Right Planting Method for Your Farm

Tractor-mounted planters significantly increase planting efficiency and uniformity compared to manual planting, enabling precise seed placement and consistent row spacing crucial for optimal crop growth. For large-scale operations, tractor-mounted equipment reduces labor costs and planting time, while manual planting remains suitable for small farms with limited resources and irregular field conditions. Selecting the appropriate method depends on farm size, budget, crop type, and desired planting accuracy to maximize yield potential and operational efficiency.

Related Important Terms

Precision Seeding

Tractor-mounted planters offer superior precision seeding for row crops by ensuring uniform seed spacing and depth, which enhances germination rates and crop yields compared to manual planting. This mechanized approach reduces seed wastage and labor intensity while optimizing planting speed and consistency under varying field conditions.

Variable Rate Planting

Tractor-mounted planters equipped with Variable Rate Planting (VRP) technology optimize seed placement and spacing based on precise soil and field variability data, significantly improving crop uniformity and yield potential compared to manual planting methods. Manual planting lacks the precision and efficiency of VRP systems, leading to inconsistent seed distribution and suboptimal resource utilization in row crop production.

Auto-Guidance Planter Systems

Tractor-mounted auto-guidance planter systems enhance planting accuracy and efficiency by consistently spacing seeds at optimal depths and intervals, reducing human error compared to manual planting. These systems integrate GPS technology and automated steering to enable precise row alignment, significantly improving crop uniformity and yield potential in large-scale row crop production.

Downforce Control (planters)

Tractor-mounted planters with advanced downforce control systems ensure precise seed placement and uniform soil contact, enhancing germination rates and crop yields compared to manual planting, which often suffers from inconsistent seed depth and variable soil pressure. Automated downforce adjustments optimize planter performance across varied field conditions, reducing soil compaction and improving overall planting efficiency in row crop production.

Seed Singulation Technology

Tractor-mounted planters equipped with advanced seed singulation technology ensure precise seed spacing and depth, significantly enhancing germination rates and crop uniformity compared to manual planting. This mechanized approach reduces seed waste and labor costs while improving overall planting efficiency in row crop production.

Real-Time Seed Spacing Mapping

Tractor-mounted planters equipped with Real-Time Seed Spacing Mapping technology ensure precise seed placement and uniform spacing, significantly enhancing crop yield and reducing seed wastage compared to manual planting methods. This advanced system continuously monitors and adjusts seed distribution on-the-go, optimizing field productivity and enabling detailed data collection for improved crop management.

Electric Drive Planters

Electric drive tractor-mounted planters significantly enhance planting precision and productivity for row crops by enabling individual row control and real-time planting adjustments. Compared to manual planting, these advanced systems reduce labor costs and improve seed placement accuracy, leading to higher germination rates and optimized crop yields.

Multi-Hybrid Planting

Tractor-mounted planters equipped with multi-hybrid technology dramatically enhance row crop efficiency by enabling precise seed placement and variable hybrid selection within a single field, optimizing yield potential and resource use. Manual planting lacks this level of precision and flexibility, resulting in inconsistent seed spacing and limited ability to adapt hybrid varieties to specific microenvironments, which can reduce overall productivity.

No-Till Planter Attachments

Tractor-mounted no-till planter attachments enhance planting efficiency by precisely placing seeds at consistent depths while minimizing soil disturbance compared to manual planting, which is labor-intensive and less uniform. These advanced attachments improve soil conservation, promote better moisture retention, and increase crop yields in row crops due to better seed-to-soil contact and reduced compaction.

Smart Planter Telemetry

Tractor-mounted planters equipped with smart telemetry systems enable precise seed placement, real-time monitoring, and data-driven adjustments that significantly improve planting efficiency and crop uniformity compared to manual planting. These advanced planters reduce labor costs, increase seed usage accuracy, and provide actionable insights through GPS integration and sensor data analytics for optimized row crop production.

Tractor-mounted planter vs manual planting for row crops Infographic

agridif.com

agridif.com