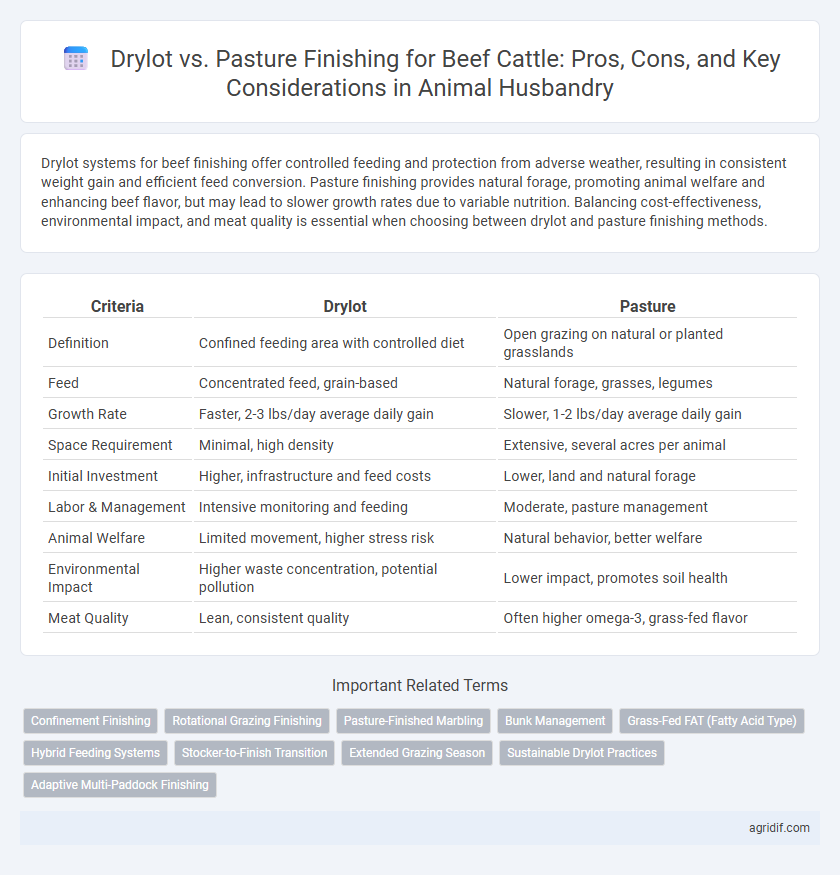

Drylot systems for beef finishing offer controlled feeding and protection from adverse weather, resulting in consistent weight gain and efficient feed conversion. Pasture finishing provides natural forage, promoting animal welfare and enhancing beef flavor, but may lead to slower growth rates due to variable nutrition. Balancing cost-effectiveness, environmental impact, and meat quality is essential when choosing between drylot and pasture finishing methods.

Table of Comparison

| Criteria | Drylot | Pasture |

|---|---|---|

| Definition | Confined feeding area with controlled diet | Open grazing on natural or planted grasslands |

| Feed | Concentrated feed, grain-based | Natural forage, grasses, legumes |

| Growth Rate | Faster, 2-3 lbs/day average daily gain | Slower, 1-2 lbs/day average daily gain |

| Space Requirement | Minimal, high density | Extensive, several acres per animal |

| Initial Investment | Higher, infrastructure and feed costs | Lower, land and natural forage |

| Labor & Management | Intensive monitoring and feeding | Moderate, pasture management |

| Animal Welfare | Limited movement, higher stress risk | Natural behavior, better welfare |

| Environmental Impact | Higher waste concentration, potential pollution | Lower impact, promotes soil health |

| Meat Quality | Lean, consistent quality | Often higher omega-3, grass-fed flavor |

Introduction to Beef Finishing Systems

Beef finishing systems primarily consist of drylot and pasture methods, each offering distinct advantages in growth rate and feed efficiency. Drylot systems provide controlled environments with concentrated feed, optimizing weight gain and carcass quality through precise nutrition management. Pasture finishing leverages natural grazing, promoting animal welfare and sustainable land use, though it may result in slower growth and variable meat characteristics.

Understanding Drylot Finishing: Principles and Practices

Drylot finishing involves confining beef cattle in a controlled environment where feed intake and nutrient composition are precisely managed to maximize weight gain and meat quality. This practice emphasizes high-energy diets, often including grains and supplements, to ensure consistent growth rates while minimizing forage variability typical of pasture systems. Effective drylot management requires monitoring animal health, waste disposal, and environmental conditions to optimize feed efficiency and maintain sustainability.

Pasture-Based Finishing: Key Concepts and Methods

Pasture-based finishing in beef production relies on rotational grazing systems that optimize forage quality and animal nutrition, promoting healthier weight gain and improved meat quality. Key methods include managing stocking density, maintaining diverse forage species, and ensuring adequate rest periods for pasture regrowth to enhance soil health and forage productivity. This approach supports sustainable practices by reducing feed costs, increasing carbon sequestration, and improving animal welfare compared to drylot finishing.

Nutritional Differences: Drylot vs Pasture

Drylot systems for beef finishing provide a controlled environment with high-energy, nutrient-dense feed such as grains and formulated supplements, ensuring consistent weight gain and uniform carcass quality. Pasture-based finishing relies on forage with variable nutrient content, often lower in energy and protein, leading to slower growth rates but potentially improved fatty acid profiles beneficial for beef quality. Understanding the nutritional differences between drylot and pasture finishing helps optimize diet formulation for targeted growth performance and meat characteristics in beef production.

Animal Health and Welfare Considerations

Drylot systems for beef finishing offer controlled environments that reduce parasite exposure and soil-borne diseases, promoting consistent hygiene and minimizing mud-related hoof problems. Pasture-based finishing provides natural foraging behavior and exercise, enhancing animal welfare and reducing respiratory issues linked to confined spaces. Balancing nutrition in pastures with proper veterinary care is essential to prevent deficiencies and maintain optimal health compared to the more manageable monitoring in drylot operations.

Environmental Impacts of Each System

Drylot beef finishing systems concentrate waste in confined areas, increasing the risk of nutrient runoff and groundwater contamination without proper manure management practices. Pasture-based finishing promotes natural nutrient cycling through vegetation, enhancing soil health and carbon sequestration while minimizing erosion and water pollution. However, pasture systems can contribute to methane emissions from enteric fermentation, necessitating integrated strategies to balance environmental impacts.

Economic Analysis: Costs and Returns

Drylot systems for beef finishing often incur higher initial capital costs due to infrastructure such as feed bunks, water systems, and manure management, but they provide precise control over feed intake, potentially enhancing feed conversion efficiency and reducing the risk of pasture-related losses. Pasture finishing typically has lower direct costs since it relies on natural forage, yet variability in forage quality and seasonal availability can impact weight gain and extend the finishing period, affecting overall returns. Economic analysis indicates that drylot finishing can yield higher average daily gains and carcass quality, offsetting increased expenses through improved market premiums, while pasture finishing suits operations with lower capital investment and focuses on niche or organic markets.

Meat Quality and Carcass Characteristics

Drylot finishing promotes consistent meat quality and enhanced marbling through controlled feeding, resulting in higher carcass yields and uniform fat distribution. Pasture finishing often produces leaner beef with a distinctive flavor profile but can lead to greater variability in carcass characteristics and lower intramuscular fat. Selecting the optimal system depends on desired meat tenderness, fat content, and market preferences for beef quality attributes.

Management Challenges and Solutions

Drylot systems for beef finishing face management challenges such as manure buildup, feed ration control, and maintaining animal health in confined spaces, requiring rigorous waste management protocols and precise nutrition plans. Pasture-based finishing demands solutions for variable forage quality, parasite control, and rotational grazing strategies to optimize grass utilization and animal growth. Implementing technology like automated feeders in drylots and monitoring forage conditions in pastures enhances productivity and addresses critical management issues.

Choosing the Right System for Your Operation

Selecting between drylot and pasture systems for beef finishing hinges on factors like land availability, climate, and cost efficiency. Drylot finishing offers controlled feeding conditions, higher weight gain rates, and better manure management, making it suitable for limited acreage or harsh climates. Pasture finishing promotes natural grazing behavior, improved meat quality, and reduced feed costs, ideal for regions with ample land and favorable weather.

Related Important Terms

Confinement Finishing

Confinement finishing in drylots allows for precise control over cattle diets, leading to faster weight gain and improved feed efficiency compared to pasture finishing. Drylot systems minimize land use and environmental impact by concentrating manure management, but require higher input costs for feed and facility maintenance.

Rotational Grazing Finishing

Rotational grazing finishing enhances beef quality by allowing cattle to graze on nutrient-rich pastures in cycles, promoting optimal forage regrowth and soil health compared to drylot systems that rely on confined feed and supplementation. This sustainable practice improves weight gain efficiency and reduces environmental impact through improved manure distribution and minimized overgrazing.

Pasture-Finished Marbling

Pasture-finished beef typically develops marbling through natural forage consumption, which enhances muscle intramuscular fat content and contributes to superior flavor profiles. This method supports sustainable grazing practices, improving soil health and animal welfare compared to drylot systems that rely heavily on grain-based diets for finishing.

Bunk Management

Effective bunk management in drylot beef finishing ensures precise feed intake control and reduces waste, optimizing growth rates and feed efficiency. In contrast, pasture finishing limits direct feed monitoring, making it challenging to manage individual animal nutrition and intake consistency.

Grass-Fed FAT (Fatty Acid Type)

Drylot finishing typically results in higher saturated fat content with a less favorable omega-3 to omega-6 ratio compared to pasture-finished beef, where grass-fed cattle accumulate greater amounts of beneficial omega-3 fatty acids and conjugated linoleic acid (CLA). Pasture-based systems enhance the fatty acid profile by increasing the concentration of alpha-linolenic acid, contributing to healthier, more desirable fat composition in beef.

Hybrid Feeding Systems

Hybrid feeding systems for beef finishing integrate drylot management with pasture grazing to optimize weight gain and feed efficiency, leveraging controlled grain-based rations alongside nutrient-rich forage. This approach enhances carcass quality and reduces environmental impact by balancing intensive drylot conditions with extensive pasture benefits.

Stocker-to-Finish Transition

Drylot systems provide controlled nutrition and reduce parasite exposure during the stocker-to-finish transition, enhancing weight gain efficiency for beef cattle. Pasture finishing promotes natural grazing behavior and forage utilization but may result in slower growth rates and variable feed intake consistency.

Extended Grazing Season

Extended grazing season in pasture-based beef finishing enhances forage utilization and reduces feed costs by allowing cattle to graze on diverse forage species longer. Drylot systems provide controlled nutrition and protect grassland from overgrazing but often require supplemental feeding during off-season periods.

Sustainable Drylot Practices

Sustainable drylot practices in beef finishing emphasize efficient manure management, water conservation, and rotational feeding strategies to minimize environmental impact and enhance soil health. Incorporating cover crops and optimizing pen design reduce erosion and nutrient runoff, promoting long-term productivity in drylot systems compared to traditional pasture methods.

Adaptive Multi-Paddock Finishing

Adaptive Multi-Paddock (AMP) finishing enhances beef production efficiency by rotating cattle through multiple small pastures, promoting superior forage regrowth and soil health compared to traditional drylot systems. This method reduces feed costs and environmental impact while improving animal welfare through increased grazing opportunities and natural behaviors.

Drylot vs Pasture for Beef Finishing Infographic

agridif.com

agridif.com