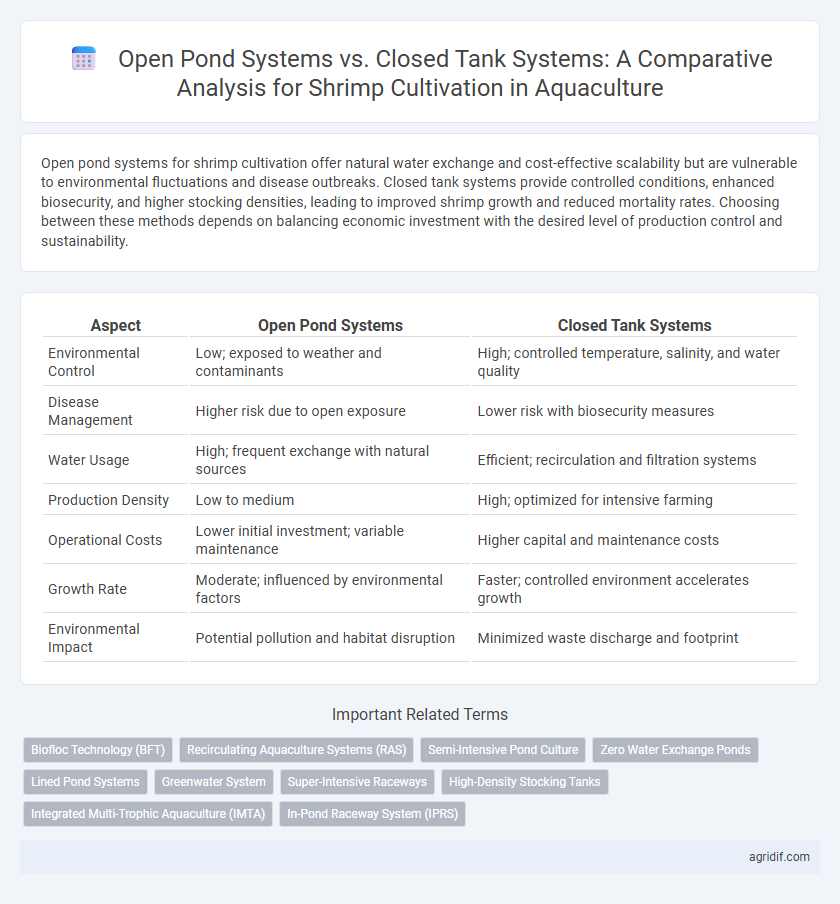

Open pond systems for shrimp cultivation offer natural water exchange and cost-effective scalability but are vulnerable to environmental fluctuations and disease outbreaks. Closed tank systems provide controlled conditions, enhanced biosecurity, and higher stocking densities, leading to improved shrimp growth and reduced mortality rates. Choosing between these methods depends on balancing economic investment with the desired level of production control and sustainability.

Table of Comparison

| Aspect | Open Pond Systems | Closed Tank Systems |

|---|---|---|

| Environmental Control | Low; exposed to weather and contaminants | High; controlled temperature, salinity, and water quality |

| Disease Management | Higher risk due to open exposure | Lower risk with biosecurity measures |

| Water Usage | High; frequent exchange with natural sources | Efficient; recirculation and filtration systems |

| Production Density | Low to medium | High; optimized for intensive farming |

| Operational Costs | Lower initial investment; variable maintenance | Higher capital and maintenance costs |

| Growth Rate | Moderate; influenced by environmental factors | Faster; controlled environment accelerates growth |

| Environmental Impact | Potential pollution and habitat disruption | Minimized waste discharge and footprint |

Introduction to Shrimp Cultivation Systems

Open Pond Systems for shrimp cultivation leverage natural water bodies or artificial earthen ponds, offering cost-effective, low-maintenance environments ideal for extensive farming. Closed Tank Systems utilize controlled, recirculating aquaculture technology, providing precise regulation of water quality, temperature, and biosecurity, enabling intensive shrimp production with higher yields. Each system presents distinct advantages and limitations in sustainability, productivity, and operational complexity within shrimp farming industry.

Overview of Open Pond Systems

Open pond systems for shrimp cultivation utilize natural or artificially dug ponds, offering extensive space for shrimp growth and lower initial investment costs compared to closed tank systems. These systems rely heavily on natural environmental conditions, which can lead to variable water quality and higher vulnerability to diseases and predators. Despite lower operational expenses, managing water quality and ensuring biosecurity remain significant challenges in open pond shrimp farming.

Overview of Closed Tank Systems

Closed tank systems for shrimp cultivation provide precise control over water quality, temperature, and biosecurity, significantly reducing disease outbreaks and environmental impact. These systems utilize recirculating aquaculture technology (RAS) to optimize water reuse, enhancing sustainability and resource efficiency compared to open pond systems. Advanced filtration and aeration methods in closed tanks enable higher stocking densities, leading to increased shrimp yield and consistent production cycles.

Water Quality Management: Open vs Closed Systems

Open pond systems rely on natural water exchange and environmental factors, often leading to variable water quality and higher risks of contamination or disease outbreaks in shrimp cultivation. Closed tank systems offer controlled water quality through advanced filtration, aeration, and recirculation technologies, ensuring stable conditions that enhance shrimp health and growth rates. Effective water quality management in closed systems reduces the need for chemical treatments and improves sustainability compared to the more unpredictable open pond environments.

Disease Control in Open and Closed Shrimp Farming

Open pond systems for shrimp cultivation face higher risks of disease outbreaks due to exposure to natural pathogens and limited control over water quality and biosecurity. Closed tank systems offer enhanced disease control through controlled environments, filtration, and disinfection technologies that minimize pathogen entry and facilitate early detection. Implementing closed systems can reduce the reliance on antibiotics and improve shrimp health and survival rates significantly compared to open pond methods.

Cost Analysis: Open Ponds versus Closed Tanks

Open pond systems for shrimp cultivation generally have lower initial capital costs due to simpler infrastructure and reliance on natural water exchange, while closed tank systems require significant investment in construction, aeration, and water treatment technologies. Operating costs in open ponds tend to be lower, but closed tanks can achieve higher production densities and better biosecurity, which may offset expenses through increased yields and reduced mortality rates. Long-term cost efficiency favors closed tank systems in high-value shrimp markets where disease control and environmental impact are critical factors.

Environmental Impact Assessment

Open pond systems for shrimp cultivation often lead to higher nutrient runoff and habitat disruption, negatively affecting local ecosystems with increased emissions of nitrogen and phosphorus. Closed tank systems minimize environmental impact by controlling water quality and waste discharge, allowing efficient recycling and reducing contamination risks. Lifecycle assessments indicate closed systems lower carbon footprint and water usage intensity, promoting sustainable aquaculture practices.

Yield and Productivity Comparison

Open Pond Systems for shrimp cultivation typically offer lower yield per unit area due to environmental fluctuations and disease exposure, with average productivity ranging from 1,000 to 3,000 kg/ha per crop. Closed Tank Systems enable precise control of water quality and biosecurity, resulting in significantly higher yields up to 10,000 kg/ha per crop and faster growth rates. Enhanced feed conversion ratios and reduced mortality rates in Closed Tank Systems contribute to superior overall productivity and profitability compared to Open Ponds.

Technology and Infrastructure Requirements

Open pond systems for shrimp cultivation require large land areas, natural water sources, and minimal infrastructure, relying on simple technology such as aerators and water pumps to maintain water quality. Closed tank systems demand advanced technology including recirculating aquaculture systems (RAS), biofilters, and sophisticated monitoring equipment, enabling precise control of water parameters and biosecurity. Infrastructure for closed systems involves durable tanks, water treatment units, and automated feeding systems, supporting higher stocking densities and year-round production.

Future Trends in Shrimp Aquaculture Systems

Emerging trends in shrimp aquaculture emphasize the transition from traditional open pond systems to advanced closed tank systems, which offer improved biosecurity and environmental control. Closed tank systems facilitate precise regulation of water quality parameters such as temperature, pH, and salinity, leading to enhanced shrimp growth rates and disease resistance. Innovations in recirculating aquaculture systems (RAS) and integrated multi-trophic aquaculture (IMTA) are set to revolutionize shrimp farming by maximizing resource efficiency and minimizing ecological impact.

Related Important Terms

Biofloc Technology (BFT)

Open Pond Systems offer extensive space and natural environmental interactions for shrimp cultivation but are prone to water quality fluctuations and disease outbreaks, whereas Closed Tank Systems provide controlled environments that enhance biosecurity and optimize feeding efficiency. Biofloc Technology (BFT) significantly improves water quality and shrimp health in both systems by promoting beneficial microbial communities that recycle waste into protein-rich biomass, reducing the need for water exchange and external feed inputs.

Recirculating Aquaculture Systems (RAS)

Recirculating Aquaculture Systems (RAS) for shrimp cultivation offer superior water quality control, reduced environmental impact, and increased biosecurity compared to traditional open pond systems, enabling higher stocking densities and consistent production cycles. Closed tank systems utilizing RAS optimize resource efficiency by recycling up to 99% of water, minimizing disease risk, and enhancing growth rates through precise management of temperature, oxygen, and waste removal.

Semi-Intensive Pond Culture

Semi-intensive pond culture in aquaculture utilizes open pond systems that leverage natural productivity combined with supplementary feeding to optimize shrimp growth, offering cost-effective scalability and easy environmental monitoring; closed tank systems, although enabling precise control over water quality and biosecurity, generally involve higher capital and operational costs, making them less favorable for large-scale semi-intensive shrimp farming. The choice between these systems impacts shrimp yield, water usage efficiency, and disease management, with open ponds being preferred in regions with suitable climate and land availability for semi-intensive production.

Zero Water Exchange Ponds

Zero water exchange ponds in open pond systems for shrimp cultivation enhance sustainability by minimizing water usage and reducing effluent discharge, unlike closed tank systems that offer precise control over environmental parameters but require higher energy inputs. These ponds rely on natural microbial processes to maintain water quality, promoting cost-effective and environmentally friendly shrimp farming.

Lined Pond Systems

Lined pond systems in shrimp aquaculture offer enhanced water quality control and reduced soil permeability compared to traditional open pond systems, resulting in lower risk of contamination and improved feed conversion ratios. These systems also enable efficient waste management and biosecurity, contributing to higher shrimp survival rates and consistent production cycles in contrast to closed tank systems.

Greenwater System

Greenwater systems in shrimp cultivation utilize photosynthetically active microalgae in open pond systems, enhancing natural feed availability, improving water quality through oxygen production, and supporting shrimp health by reducing pathogen load. Closed tank systems, while offering controlled environmental parameters, often lack the extensive biodiversity and cost-effective nutrient recycling found in open greenwater ponds, making open systems more sustainable for large-scale shrimp aquaculture.

Super-Intensive Raceways

Super-intensive raceway systems, a type of closed tank system, provide enhanced control over water quality, disease management, and feeding efficiency compared to open pond systems, leading to higher shrimp yield per unit area. These raceways enable continuous water circulation and aeration, optimizing oxygen levels and waste removal, which is critical for maintaining optimal growth conditions in high-density shrimp cultivation.

High-Density Stocking Tanks

High-density stocking tanks in closed tank systems for shrimp cultivation enable precise control over water quality, temperature, and biosecurity, resulting in higher growth rates and reduced disease outbreaks compared to open pond systems. These systems optimize space utilization and improve feed conversion ratios, making them more efficient and sustainable for intensive shrimp production.

Integrated Multi-Trophic Aquaculture (IMTA)

Open pond systems in shrimp cultivation allow for natural nutrient recycling but often face challenges in water quality management, making them less compatible with Integrated Multi-Trophic Aquaculture (IMTA) compared to closed tank systems. Closed tank systems provide controlled environments that enhance the integration of multiple species such as shrimp, seaweed, and filter feeders, optimizing nutrient exchange and improving overall system sustainability in IMTA practices.

In-Pond Raceway System (IPRS)

In shrimp cultivation, the In-Pond Raceway System (IPRS) enhances productivity by combining the natural benefits of open pond systems with the controlled environment of closed tanks, improving water circulation and oxygenation while reducing waste accumulation. IPRS maximizes growth rates and feed efficiency through aerated raceways, which facilitate easier harvesting and disease management compared to traditional open ponds or closed tank systems.

Open Pond Systems vs Closed Tank Systems for shrimp cultivation Infographic

agridif.com

agridif.com