Recirculating Aquaculture Systems (RAS) optimize water usage by continuously filtering and reusing water, reducing environmental impact and operational costs compared to Flow-through Systems that rely on constant water exchange. RAS provide precise control over water quality parameters, enhancing fish health and growth rates, whereas Flow-through Systems depend heavily on uncontaminated water sources and may contribute to habitat disruption due to discharge. Implementing RAS is increasingly favored for sustainable aquaculture practices, offering significant benefits in areas with limited water availability.

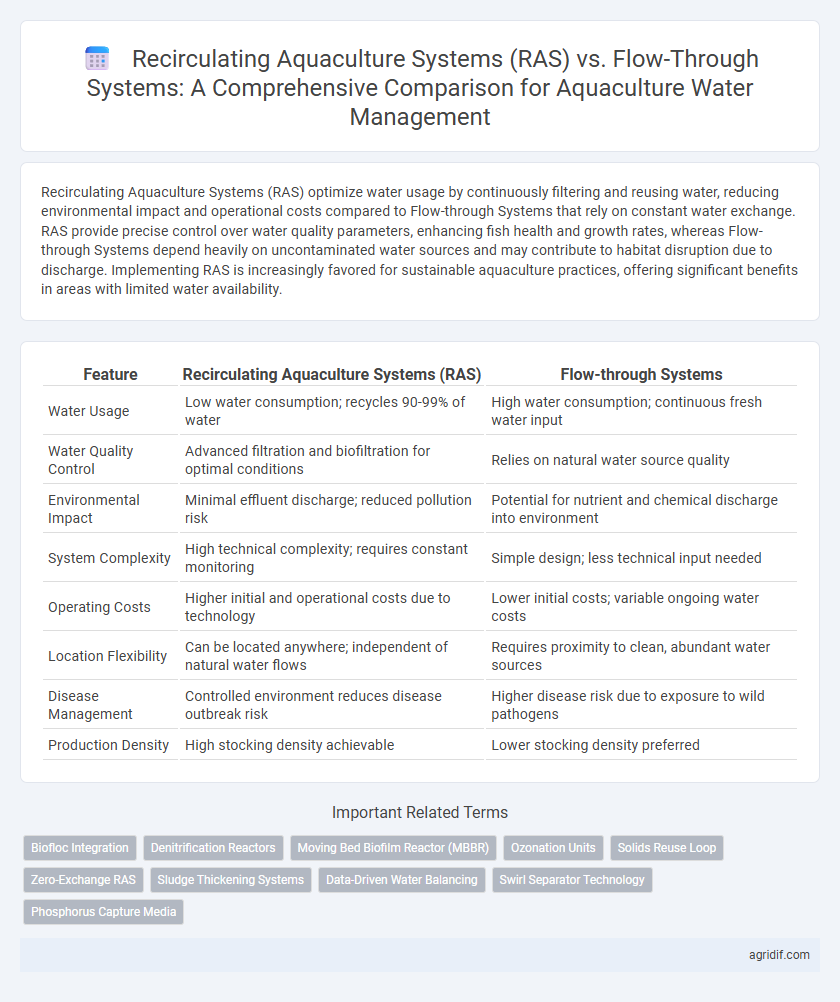

Table of Comparison

| Feature | Recirculating Aquaculture Systems (RAS) | Flow-through Systems |

|---|---|---|

| Water Usage | Low water consumption; recycles 90-99% of water | High water consumption; continuous fresh water input |

| Water Quality Control | Advanced filtration and biofiltration for optimal conditions | Relies on natural water source quality |

| Environmental Impact | Minimal effluent discharge; reduced pollution risk | Potential for nutrient and chemical discharge into environment |

| System Complexity | High technical complexity; requires constant monitoring | Simple design; less technical input needed |

| Operating Costs | Higher initial and operational costs due to technology | Lower initial costs; variable ongoing water costs |

| Location Flexibility | Can be located anywhere; independent of natural water flows | Requires proximity to clean, abundant water sources |

| Disease Management | Controlled environment reduces disease outbreak risk | Higher disease risk due to exposure to wild pathogens |

| Production Density | High stocking density achievable | Lower stocking density preferred |

Introduction to Aquaculture Water Management

Recirculating Aquaculture Systems (RAS) offer superior water management by filtering and reusing up to 99% of water, significantly reducing freshwater consumption compared to traditional flow-through systems that discharge large volumes of untreated water. RAS enables precise control of water quality parameters such as temperature, oxygen, and nitrogen compounds, enhancing fish health and growth rates while minimizing environmental impact. Flow-through systems, reliant on continuous fresh water input, face challenges with effluent management and higher operational costs due to water use and treatment requirements.

Overview of Recirculating Aquaculture Systems (RAS)

Recirculating Aquaculture Systems (RAS) utilize advanced filtration technology to continuously clean and recycle water within the system, significantly reducing water usage compared to flow-through systems. By maintaining controlled environmental conditions such as temperature, oxygen levels, and waste removal, RAS enhances fish health and growth rates while minimizing environmental impact. These systems enable sustainable aquaculture operations in limited spaces, promoting resource efficiency through closed-loop water management.

Understanding Flow-through Aquaculture Systems

Flow-through aquaculture systems continuously supply fresh water through fish tanks or ponds, ensuring stable water quality by diluting waste and maintaining oxygen levels without water recirculation. These systems rely heavily on abundant clean water sources and efficient discharge management to prevent environmental contamination from nutrients and organic matter. Flow-through systems are simpler to operate than recirculating aquaculture systems (RAS) but pose challenges in water conservation and effluent treatment.

Water Use Efficiency: RAS vs Flow-through Systems

Recirculating Aquaculture Systems (RAS) achieve superior water use efficiency by continuously filtering and reusing water, reducing consumption by up to 90% compared to flow-through systems. Flow-through systems rely on a constant influx of fresh water, leading to higher water withdrawal and increased environmental impact. RAS technology enables precise control of water quality and volume, making it the preferred choice for sustainable aquaculture water management.

Environmental Impact Comparison

Recirculating Aquaculture Systems (RAS) significantly reduce water usage by recycling and treating water, minimizing effluent discharge and nutrient pollution compared to Flow-through Systems that continuously consume large volumes of water and release untreated waste into natural water bodies. RAS enhances environmental sustainability by controlling ammonia, nitrite, and nitrate levels through biofiltration, leading to lower risks of eutrophication and habitat degradation often associated with flow-through operations. Energy consumption in RAS can be higher due to system complexity, but advances in technology are improving efficiency, making it a preferable option for reducing aquaculture's ecological footprint.

Operational and Maintenance Requirements

Recirculating Aquaculture Systems (RAS) demand intensive operational oversight, including continuous water quality monitoring, mechanical filtration maintenance, and biofilter management to ensure optimal fish health. Flow-through systems require less technological intervention but rely heavily on consistent freshwater supply and frequent water replacement, increasing water usage and potential environmental impact. Maintenance in RAS centers around system component durability and routine checks to prevent biofouling, whereas flow-through systems focus on managing inflow-outflow infrastructure and mitigating effluent discharge.

Water Quality Control Methods

Recirculating Aquaculture Systems (RAS) utilize advanced biofiltration, mechanical filtration, and UV sterilization to maintain optimal water quality by continuously recycling and treating water within a closed loop. Flow-through systems rely on a constant inflow and outflow of fresh water, which dilutes waste and maintains water parameters but requires significantly higher volumes of water and offers less control over contaminants. In terms of water quality control, RAS provides precise management of ammonia, nitrite, and nitrate levels, leading to enhanced fish health and reduced environmental impact compared to traditional flow-through systems.

Energy Consumption and Sustainability

Recirculating Aquaculture Systems (RAS) utilize advanced water filtration and treatment technologies to minimize water usage, resulting in significantly lower energy consumption per unit of biomass produced compared to Flow-through Systems, which rely on continuous water exchange. RAS enhances sustainability by reducing environmental discharge and enabling precise control of water quality parameters, thereby supporting higher stocking densities and disease management. Despite higher initial energy inputs for pumps and biofilters, RAS offers long-term energy efficiency and resource conservation advantages over the less sustainable, energy-intensive Flow-through approach.

Suitability for Different Species and Scales

Recirculating Aquaculture Systems (RAS) offer precise water quality control suitable for high-value species such as salmon and barramundi, adapting well to small-scale, urban, or research-based operations. Flow-through systems, relying on continuous water exchange, are typically more appropriate for species like catfish or tilapia, thriving in large-scale, pond-based environments where water availability is abundant. RAS provides scalability with reduced environmental impact and biosecurity benefits, while flow-through systems excel in simplicity and lower initial capital costs for extensive production.

Economic Considerations and Long-term Viability

Recirculating Aquaculture Systems (RAS) offer higher initial capital costs compared to Flow-through Systems but provide significant long-term economic advantages through reduced water usage and enhanced biosecurity. The ability of RAS to recycle water decreases dependency on external water sources, lowering operational expenses and environmental impact over time. While Flow-through Systems require continuous water supply, resulting in increased utility costs and vulnerability to fluctuating water availability, RAS present a more sustainable and economically viable solution for intensive aquaculture production.

Related Important Terms

Biofloc Integration

Recirculating Aquaculture Systems (RAS) optimize water use by filtering and reusing water, reducing environmental discharge compared to flow-through systems that continuously replace water. Integrating biofloc technology in RAS enhances nutrient recycling and improves water quality by promoting beneficial microbial communities that convert waste into feed, boosting sustainability and production efficiency.

Denitrification Reactors

Denitrification reactors in Recirculating Aquaculture Systems (RAS) efficiently remove nitrates through controlled anaerobic processes, enhancing water quality and reducing harmful nitrogen buildup compared to Flow-through Systems, which require continuous freshwater input and generate higher nitrate discharge. Optimizing denitrification reactors in RAS supports sustainable water management by minimizing environmental impact and lowering operational costs associated with water treatment and disposal.

Moving Bed Biofilm Reactor (MBBR)

Recirculating Aquaculture Systems (RAS) utilize Moving Bed Biofilm Reactor (MBBR) technology to enhance water quality by promoting efficient biofiltration on carrier media, significantly reducing water exchange rates compared to traditional flow-through systems. MBBR in RAS optimizes nitrogen removal and organic matter degradation, leading to improved system sustainability and decreased environmental impact in intensive aquaculture operations.

Ozonation Units

Recirculating Aquaculture Systems (RAS) utilize advanced ozonation units to maintain optimal water quality by effectively reducing organic waste, pathogens, and dissolved gases, enhancing fish health and growth rates. In contrast, flow-through systems rely less on ozonation, as water is continuously replaced, leading to higher water usage and less efficient control of microbial contamination.

Solids Reuse Loop

Recirculating Aquaculture Systems (RAS) enhance sustainability by incorporating a solids reuse loop that efficiently captures and recycles organic waste, reducing water consumption and improving nutrient recovery compared to Flow-through Systems that discharge solids with minimal reuse. This closed-loop approach in RAS minimizes environmental impact, optimizes water quality, and supports higher stocking densities through advanced solids removal and treatment technologies.

Zero-Exchange RAS

Zero-exchange Recirculating Aquaculture Systems (RAS) optimize water management by continuously filtering and reusing water, drastically reducing the need for fresh water intake compared to traditional flow-through systems that rely on constant water replacement. This approach enhances sustainability and biosecurity by minimizing effluent discharge and maintaining stable water quality essential for high-density fish farming.

Sludge Thickening Systems

Recirculating Aquaculture Systems (RAS) employ advanced sludge thickening systems that efficiently concentrate solid waste, reducing water usage and improving water quality compared to flow-through systems which discharge untreated sludge and consume high volumes of fresh water. Optimized sludge thickening in RAS enhances nutrient recovery and lowers environmental impact by minimizing effluent discharge, crucial for sustainable aquaculture water management.

Data-Driven Water Balancing

Recirculating Aquaculture Systems (RAS) leverage real-time data analytics for precise water balancing, significantly reducing water usage and enhancing biosecurity compared to Flow-through Systems, which rely on continuous freshwater intake and discharge. Advanced sensors and machine learning algorithms in RAS enable dynamic adjustment of water quality parameters, optimizing fish health and system efficiency through data-driven water management.

Swirl Separator Technology

Swirl separator technology enhances Recirculating Aquaculture Systems (RAS) by efficiently removing solid waste particles, improving water quality, and reducing water usage compared to traditional flow-through systems. This innovation supports sustainable aquaculture practices by minimizing environmental impact and operational costs through effective sediment separation and recycling of water within RAS.

Phosphorus Capture Media

Recirculating Aquaculture Systems (RAS) utilize advanced phosphorus capture media to significantly reduce nutrient discharge by recycling and treating water within the system, enhancing sustainability and minimizing environmental impact. Flow-through systems, in contrast, rely on continuous water replacement with limited phosphorus removal, leading to higher nutrient effluent concentrations and environmental risks.

Recirculating Aquaculture Systems (RAS) vs Flow-through Systems for water management Infographic

agridif.com

agridif.com