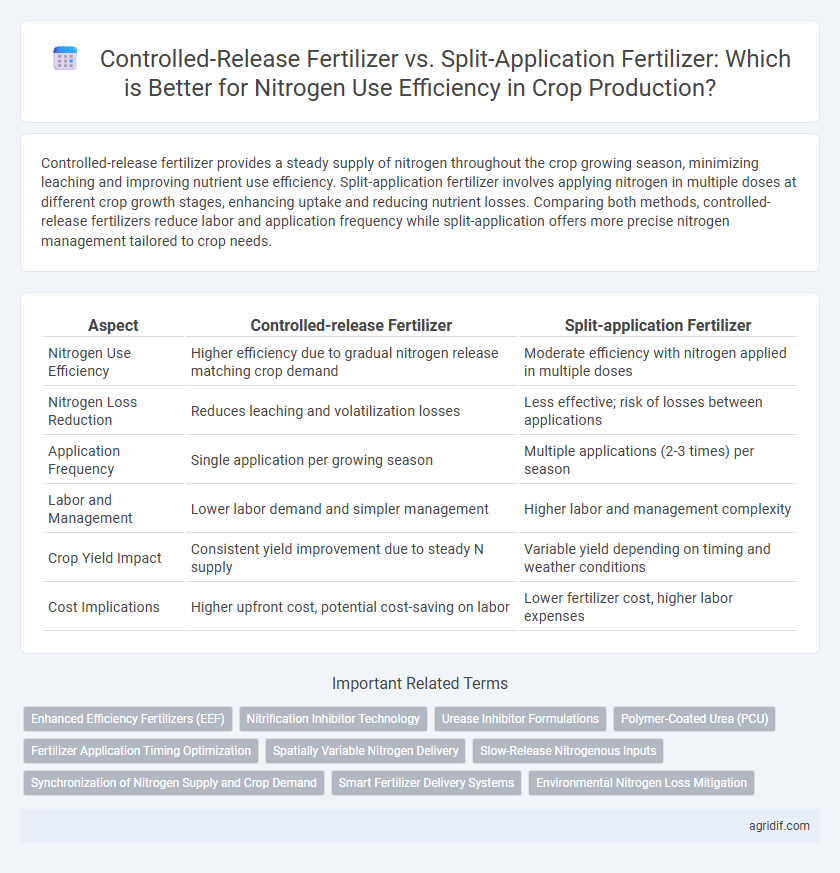

Controlled-release fertilizer provides a steady supply of nitrogen throughout the crop growing season, minimizing leaching and improving nutrient use efficiency. Split-application fertilizer involves applying nitrogen in multiple doses at different crop growth stages, enhancing uptake and reducing nutrient losses. Comparing both methods, controlled-release fertilizers reduce labor and application frequency while split-application offers more precise nitrogen management tailored to crop needs.

Table of Comparison

| Aspect | Controlled-release Fertilizer | Split-application Fertilizer |

|---|---|---|

| Nitrogen Use Efficiency | Higher efficiency due to gradual nitrogen release matching crop demand | Moderate efficiency with nitrogen applied in multiple doses |

| Nitrogen Loss Reduction | Reduces leaching and volatilization losses | Less effective; risk of losses between applications |

| Application Frequency | Single application per growing season | Multiple applications (2-3 times) per season |

| Labor and Management | Lower labor demand and simpler management | Higher labor and management complexity |

| Crop Yield Impact | Consistent yield improvement due to steady N supply | Variable yield depending on timing and weather conditions |

| Cost Implications | Higher upfront cost, potential cost-saving on labor | Lower fertilizer cost, higher labor expenses |

Introduction to Nitrogen Fertilizer Strategies

Controlled-release fertilizers (CRFs) deliver nitrogen gradually to match crop uptake, reducing leaching and improving nitrogen use efficiency. Split-application fertilizers involve multiple nitrogen applications timed to crop growth stages, enhancing nutrient availability and minimizing losses. Both strategies aim to optimize nitrogen supply, increase yield, and reduce environmental impact in crop production systems.

Understanding Controlled-Release Fertilizers

Controlled-release fertilizers (CRFs) provide a steady supply of nitrogen by releasing nutrients gradually in response to soil moisture and temperature, enhancing nitrogen use efficiency compared to split-application fertilizers. CRFs reduce nitrogen losses through leaching and volatilization, leading to improved crop nitrogen uptake and higher yields in crops such as corn and wheat. Understanding CRF formulations and release mechanisms is essential for optimizing nitrogen management and minimizing environmental impacts in modern crop production systems.

What is Split-Application Fertilizer?

Split-application fertilizer involves dividing the total nitrogen fertilizer dose into multiple applications during the crop growth cycle to match the plant's nutrient uptake demand. This method enhances nitrogen use efficiency by reducing losses through leaching and volatilization, improving crop yield and minimizing environmental impact. Commonly applied in cereals and maize, it allows precise timing based on soil tests and crop development stages.

Nitrogen Efficiency: Controlled-Release vs Split-Application

Controlled-release fertilizers improve nitrogen use efficiency by synchronizing nutrient release with crop demand, minimizing leaching and volatilization losses. Split-application fertilizers enhance nitrogen uptake by applying smaller doses at critical growth stages, reducing nitrogen loss but requiring more labor and management. Studies show controlled-release formulations can increase nitrogen use efficiency by up to 30% compared to traditional split applications in various crops.

Impact on Crop Yield and Quality

Controlled-release fertilizers enhance nitrogen use efficiency by steadily supplying nutrients, resulting in improved crop yield and higher nutritional quality compared to split-application fertilizers that deliver nitrogen in multiple doses. Studies demonstrate that controlled-release formulations reduce nitrogen losses through leaching and volatilization, leading to more consistent nitrogen availability during critical growth stages. Consequently, crops exhibit stronger biomass accumulation, increased protein content, and better overall market value under controlled-release fertilizer regimes.

Environmental Implications and Nitrogen Leaching

Controlled-release fertilizers minimize nitrogen leaching by releasing nutrients gradually, aligning with plant uptake and reducing environmental contamination in crop production. Split-application fertilizers apply nitrogen in multiple doses, improving nitrogen use efficiency but still posing risks of leaching under improper timing or heavy rainfall. Environmental implications favor controlled-release technology for reducing nitrogen runoff and groundwater pollution.

Application Timing and Farm Management

Controlled-release fertilizers provide a steady nitrogen supply that aligns with crop growth stages, reducing nutrient loss and labor frequency, which enhances application timing precision and simplifies farm management. Split-application fertilizers allow farmers to apply nitrogen multiple times based on crop needs and soil testing, offering flexibility in response to weather and crop development but requiring more labor and careful scheduling. Both approaches improve nitrogen use efficiency, with controlled-release being ideal for reducing application events and split-application maximizing adaptability to dynamic field conditions.

Cost Analysis and Economic Viability

Controlled-release fertilizers (CRFs) often involve higher upfront costs compared to split-application fertilizers due to advanced technology and manufacturing processes. However, CRFs reduce labor and operational expenses by minimizing the number of fertilizer applications, enhancing nitrogen use efficiency and potentially increasing crop yield profitability. Split-application fertilizers require multiple field visits and increased application costs, which may lower economic viability despite lower material costs.

Suitability for Different Crops and Soil Types

Controlled-release fertilizers provide a consistent nitrogen supply ideal for crops with long growing seasons or those sensitive to nitrogen fluctuations, such as cereals and legumes, especially in sandy or loamy soils prone to nutrient leaching. Split-application fertilizers allow precise timing of nitrogen delivery, benefiting crops with distinct growth stages like maize and vegetables, and are suitable for diverse soil types including clay soils with higher nutrient retention. Matching fertilizer type to crop nitrogen demand patterns and soil nutrient dynamics enhances nitrogen use efficiency and crop yield.

Future Trends in Nitrogen Fertilizer Technologies

Controlled-release fertilizers offer enhanced nitrogen use efficiency by gradually supplying nutrients, reducing leaching and volatilization compared to traditional split-application methods. Future trends emphasize integrating nanotechnology and smart sensors with controlled-release formulations to optimize nitrogen delivery based on real-time crop needs and soil conditions. These advancements aim to maximize crop yield, minimize environmental impact, and promote sustainable crop production systems.

Related Important Terms

Enhanced Efficiency Fertilizers (EEF)

Controlled-release fertilizers (CRFs) provide a steady nitrogen supply through encapsulation techniques, optimizing nutrient availability and reducing leaching losses compared to split-application fertilizers, which deliver nitrogen in multiple doses throughout the growing season. Enhanced Efficiency Fertilizers (EEF) such as CRFs improve nitrogen use efficiency, promote sustained crop uptake, and minimize environmental impacts, making them advantageous for precision nutrient management in crop production.

Nitrification Inhibitor Technology

Controlled-release fertilizers combined with nitrification inhibitor technology effectively reduce nitrogen losses by slowing the conversion of ammonium to nitrate, enhancing nitrogen use efficiency and minimizing environmental impact. Split-application fertilizers allow precise nitrogen timing but lack the sustained release benefits and nitrification suppression that controlled-release formulations provide for optimizing crop nitrogen uptake.

Urease Inhibitor Formulations

Controlled-release fertilizers with urease inhibitor formulations enhance nitrogen use efficiency by reducing ammonia volatilization and providing a steady nutrient supply, optimizing crop growth and yield. Split-application of nitrogen can mitigate losses but often requires more precise timing and labor, making urease inhibitor-coated fertilizers a more effective and convenient option for sustained nitrogen availability in crop production.

Polymer-Coated Urea (PCU)

Polymer-Coated Urea (PCU) as a controlled-release fertilizer improves nitrogen use efficiency by steadily supplying nitrogen to crops over an extended period, reducing leaching and volatilization losses compared to split-application fertilizers. This sustained nutrient release enhances crop yield and quality while minimizing environmental impact through lowered nitrogen runoff and greenhouse gas emissions.

Fertilizer Application Timing Optimization

Controlled-release fertilizers improve nitrogen use efficiency by releasing nutrients gradually, aligning with crop nitrogen demand and reducing leaching losses. Split-application fertilizer timing targets critical growth stages, optimizing nitrogen availability and minimizing waste through multiple targeted applications.

Spatially Variable Nitrogen Delivery

Controlled-release fertilizers provide spatially variable nitrogen delivery by gradually releasing nutrients in sync with crop uptake patterns, enhancing nitrogen use efficiency and reducing losses. Split-application fertilizers allow targeted nitrogen application at different growth stages, optimizing nutrient availability based on specific spatial and temporal crop demands.

Slow-Release Nitrogenous Inputs

Controlled-release fertilizers provide a steady supply of nitrogen, reducing leaching and volatilization losses, which enhances nitrogen use efficiency and supports sustained crop growth. In contrast, split-application fertilizers apply nitrogen in multiple stages, matching crop nutrient demand peaks but may increase labor and risk of nitrogen loss between applications.

Synchronization of Nitrogen Supply and Crop Demand

Controlled-release fertilizers provide a steady nitrogen release that closely matches crop nitrogen uptake patterns, reducing losses and improving nutrient use efficiency; split-application fertilizers allow for targeted nitrogen supply at critical growth stages but may risk timing mismatches. Synchronizing nitrogen availability with crop demand enhances nitrogen use efficiency and supports optimal crop yield and quality in both fertilization strategies.

Smart Fertilizer Delivery Systems

Controlled-release fertilizers optimize nitrogen use efficiency by gradually releasing nutrients according to crop demand, reducing leaching and environmental impact. Split-application fertilizers allow precise timing of nitrogen application, minimizing losses but requiring more labor and management compared to smart controlled-release delivery systems.

Environmental Nitrogen Loss Mitigation

Controlled-release fertilizers release nitrogen slowly over time, reducing leaching and volatilization compared to split-application fertilizers, which apply nitrogen in multiple doses and can lead to higher losses due to timing mismatches with crop uptake. Studies show controlled-release technology improves nitrogen use efficiency and significantly mitigates environmental nitrogen losses, enhancing sustainable crop production practices.

Controlled-release fertilizer vs Split-application fertilizer for nitrogen use Infographic

agridif.com

agridif.com