Automatic calf feeders provide precise control over milk intake and feeding schedules, improving growth rates and reducing labor demands in calf management. Manual calf feeding requires constant human involvement, increasing the risk of inconsistent feeding and hygiene issues, which can affect calf health. Integrating automatic feeders enhances efficiency, consistency, and overall welfare in dairy farming operations.

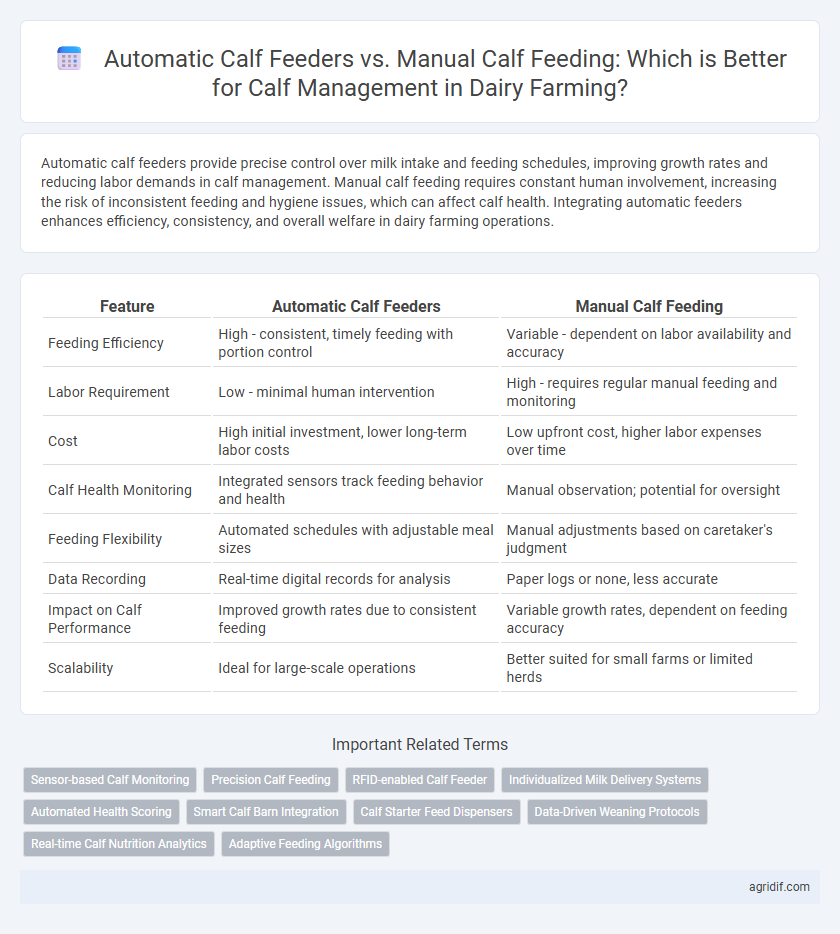

Table of Comparison

| Feature | Automatic Calf Feeders | Manual Calf Feeding |

|---|---|---|

| Feeding Efficiency | High - consistent, timely feeding with portion control | Variable - dependent on labor availability and accuracy |

| Labor Requirement | Low - minimal human intervention | High - requires regular manual feeding and monitoring |

| Cost | High initial investment, lower long-term labor costs | Low upfront cost, higher labor expenses over time |

| Calf Health Monitoring | Integrated sensors track feeding behavior and health | Manual observation; potential for oversight |

| Feeding Flexibility | Automated schedules with adjustable meal sizes | Manual adjustments based on caretaker's judgment |

| Data Recording | Real-time digital records for analysis | Paper logs or none, less accurate |

| Impact on Calf Performance | Improved growth rates due to consistent feeding | Variable growth rates, dependent on feeding accuracy |

| Scalability | Ideal for large-scale operations | Better suited for small farms or limited herds |

Introduction to Calf Feeding in Dairy Farming

Automatic calf feeders improve calf management by providing consistent feeding schedules and precise milk measurements, promoting optimal growth and health. Manual calf feeding requires labor-intensive routines and risks inconsistent feeding volumes, potentially impacting calf development. Incorporating automatic feeders enhances data tracking and reduces labor costs, making them increasingly popular in modern dairy farming operations.

Overview of Manual Calf Feeding Methods

Manual calf feeding methods typically involve bottle feeding or bucket feeding, where calves receive milk or milk replacer according to a set schedule. These methods allow for direct observation of each calf's intake and health, enabling timely intervention if feeding issues arise. However, manual feeding can be labor-intensive and variable in consistency compared to automatic calf feeders.

What Are Automatic Calf Feeders?

Automatic calf feeders are computerized systems designed to deliver precise amounts of milk or milk replacer to calves at scheduled intervals, promoting consistent nutrition and improved growth rates. These feeders monitor individual calf intake, feeding behavior, and health parameters, enabling better management and early detection of illness. By reducing labor demands and standardizing feeding routines, automatic calf feeders enhance overall calf welfare and farm efficiency compared to manual feeding methods.

Comparing Labor Requirements

Automatic calf feeders significantly reduce labor requirements by automating milk delivery, allowing a single worker to manage feeding for numerous calves simultaneously. Manual calf feeding demands continuous, time-intensive effort to individually prepare and deliver milk, increasing labor costs and limiting scalability. Transitioning to automatic feeders enhances efficiency and frees labor resources for other critical farm tasks.

Impact on Calf Health and Growth

Automatic calf feeders improve calf health and growth by providing precise, consistent milk portions tailored to individual nutritional needs, reducing the risk of overfeeding or underfeeding. These systems enhance hygiene by minimizing human contact and contamination, leading to lower incidences of diarrhea and respiratory illnesses. Manual feeding often results in irregular feeding schedules and variable milk quality, which can hinder optimal growth rates and increase the likelihood of health issues in calves.

Consistency and Precision in Feeding

Automatic calf feeders deliver precise, measured milk quantities consistently, promoting uniform growth and reducing the risk of underfeeding or overfeeding. Manual calf feeding often varies due to human error, leading to inconsistent feeding times and volumes that can affect calf health and development. Consistency and precision in feeding are critical to improving calf immunity and overall productivity on dairy farms.

Cost Analysis: Initial Investment vs Long-term Savings

Automatic calf feeders require a higher initial investment, often ranging from $10,000 to $30,000 depending on the system size and features, compared to manual feeding tools that cost under $500. Long-term savings from automatic feeders arise through reduced labor costs, improved calf growth rates, and better health outcomes, potentially cutting labor expenses by 30-50% annually. Manual feeding incurs ongoing labor expenses and risks inconsistent feeding, which may increase veterinary costs and reduce overall herd productivity.

Biosecurity and Hygiene Considerations

Automatic calf feeders enhance biosecurity by minimizing human contact, reducing the risk of disease transmission compared to manual calf feeding methods. These systems maintain consistent hygiene standards through automated cleaning protocols that prevent contamination of feeding equipment. In contrast, manual feeding requires diligent sanitation practices and poses higher risks of pathogen spread due to direct handling and shared feeding utensils.

Technological Integration and Data Monitoring

Automatic calf feeders enhance calf management by integrating advanced technologies such as RFID identification and precise milk delivery systems, ensuring consistent feeding schedules and portions tailored to each calf. These systems collect real-time data on feeding behavior, intake volumes, and growth rates, enabling early detection of health issues and optimizing nutrition strategies. In contrast, manual calf feeding lacks continuous data monitoring, relying on human observation, which may result in less precise feeding and delayed responses to health concerns.

Choosing the Best Calf Feeding System for Your Farm

Automatic calf feeders enhance calf nutrition management by providing precise milk portion control and consistent feeding schedules, reducing labor costs and minimizing human error. Manual calf feeding allows for individualized attention and monitoring but requires more time and labor, potentially leading to inconsistencies in feeding routines. Selecting the best calf feeding system depends on farm size, labor availability, and the desired balance between automation efficiency and personalized calf care.

Related Important Terms

Sensor-based Calf Monitoring

Sensor-based automatic calf feeders enhance calf management by providing precise feeding schedules and real-time monitoring of intake, health, and behavior, leading to improved growth rates and early disease detection. Manual feeding lacks continuous data collection and precise measurement, resulting in less consistent feeding routines and delayed response to health issues.

Precision Calf Feeding

Automatic calf feeders enhance precision calf feeding by delivering accurate milk volumes tailored to each calf's nutritional needs, improving growth rates and health outcomes while reducing labor time. In contrast, manual calf feeding often results in inconsistent feeding schedules and quantities, limiting the ability to optimize individual calf performance and overall farm productivity.

RFID-enabled Calf Feeder

RFID-enabled automatic calf feeders improve calf management by providing precise feeding schedules, tracking individual intake, and promoting consistent nutrition, reducing labor costs and human error compared to manual calf feeding. This technology ensures optimal growth and health monitoring through real-time data, enhancing overall herd performance and welfare.

Individualized Milk Delivery Systems

Automatic calf feeders provide precise, individualized milk delivery systems that adapt to each calf's intake needs, promoting optimal growth and health compared to manual calf feeding. These systems reduce labor intensity, ensure consistent feeding patterns, and enable detailed monitoring of each calf's consumption and behavior for improved management decisions.

Automated Health Scoring

Automatic calf feeders integrate real-time monitoring with automated health scoring systems, enabling precise tracking of calf growth, feeding behavior, and early identification of health issues. Manual calf feeding relies on subjective observation, often missing subtle signs of distress, which can delay intervention and impact calf welfare and productivity.

Smart Calf Barn Integration

Automatic calf feeders enhance calf management by integrating with Smart Calf Barn systems, enabling precise control of feeding schedules, monitoring calf health, and optimizing milk intake through sensor-driven data analytics. Compared to manual calf feeding, these automated systems reduce labor, minimize human error, and support individualized nutrition plans critical for growth and disease prevention in dairy farming.

Calf Starter Feed Dispensers

Automatic calf feeders equipped with calf starter feed dispensers ensure precise, consistent delivery of nutrient-rich starter feeds, promoting optimal growth and reducing labor costs compared to manual feeding methods. These systems enable individualized feeding schedules and portion control, enhancing calf health and intake monitoring while minimizing the risk of contamination and feed wastage.

Data-Driven Weaning Protocols

Automatic calf feeders enable precise monitoring of individual calf intake and growth metrics, facilitating data-driven weaning protocols that optimize health and development outcomes. Manual calf feeding lacks consistent data collection capabilities, making it challenging to tailor weaning schedules based on real-time calf performance and behavior.

Real-time Calf Nutrition Analytics

Automatic calf feeders provide real-time calf nutrition analytics by continuously monitoring intake and growth metrics, enabling precise adjustments to feeding protocols for optimal health and development. In contrast, manual calf feeding relies on periodic observations and estimations, limiting the accuracy and responsiveness of nutrition management in calf rearing programs.

Adaptive Feeding Algorithms

Automatic calf feeders equipped with adaptive feeding algorithms optimize nutrient intake by adjusting feeding volumes based on individual calf growth rates and health data, enhancing growth performance and disease resistance. Manual calf feeding lacks this precision, often leading to inconsistent feeding amounts and timing, which can hinder optimal calf development and increase labor requirements.

Automatic calf feeders vs Manual calf feeding for calf management Infographic

agridif.com

agridif.com