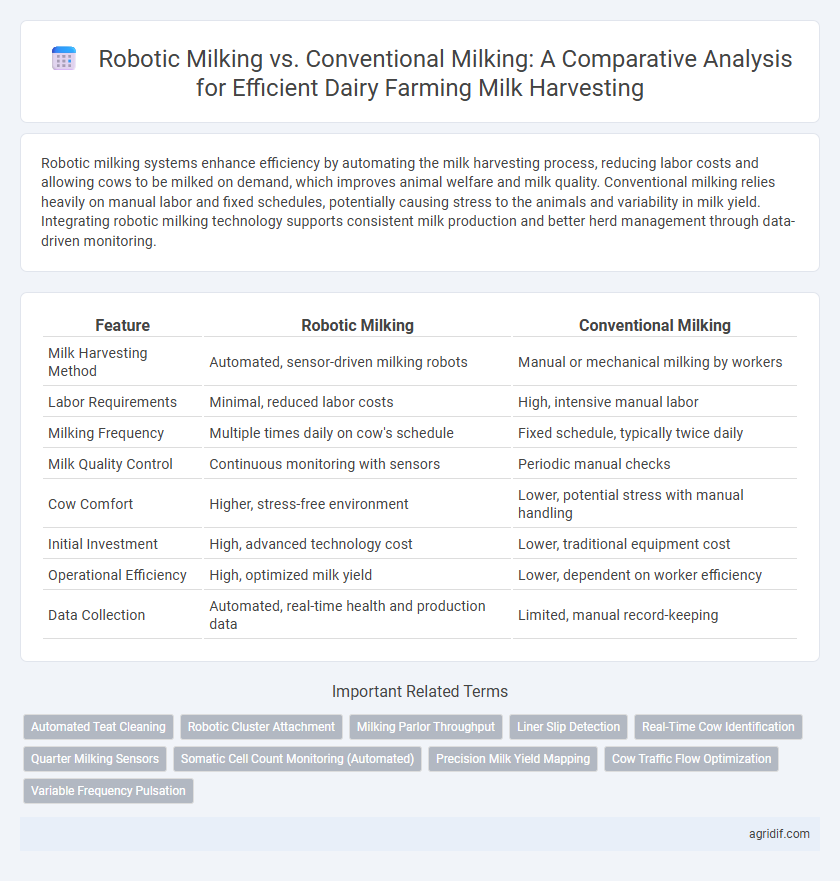

Robotic milking systems enhance efficiency by automating the milk harvesting process, reducing labor costs and allowing cows to be milked on demand, which improves animal welfare and milk quality. Conventional milking relies heavily on manual labor and fixed schedules, potentially causing stress to the animals and variability in milk yield. Integrating robotic milking technology supports consistent milk production and better herd management through data-driven monitoring.

Table of Comparison

| Feature | Robotic Milking | Conventional Milking |

|---|---|---|

| Milk Harvesting Method | Automated, sensor-driven milking robots | Manual or mechanical milking by workers |

| Labor Requirements | Minimal, reduced labor costs | High, intensive manual labor |

| Milking Frequency | Multiple times daily on cow's schedule | Fixed schedule, typically twice daily |

| Milk Quality Control | Continuous monitoring with sensors | Periodic manual checks |

| Cow Comfort | Higher, stress-free environment | Lower, potential stress with manual handling |

| Initial Investment | High, advanced technology cost | Lower, traditional equipment cost |

| Operational Efficiency | High, optimized milk yield | Lower, dependent on worker efficiency |

| Data Collection | Automated, real-time health and production data | Limited, manual record-keeping |

Introduction to Milking Technologies in Dairy Farming

Robotic milking systems utilize automated technology to harvest milk, enhancing efficiency by allowing cows to be milked multiple times a day without human intervention. Conventional milking relies on manual or semi-automated processes that require scheduled labor and often limit milking frequency to two or three times daily. The integration of sensors and data analytics in robotic milking optimizes milk yield and cow health monitoring, contrasting with traditional methods that depend heavily on routine human observation and management.

Overview of Robotic Milking Systems

Robotic milking systems automate the milk harvesting process by using sensor technology and robotic arms to attach milking cups to cows, reducing labor costs and improving milking efficiency. These systems continuously monitor udder health and milk quality through integrated sensors, providing real-time data to farmers for better herd management. Compared to conventional milking, robotic systems enable flexible milking schedules, enhance animal welfare, and increase overall milk yield through consistent milking intervals.

Conventional Milking: Methods and Practices

Conventional milking in dairy farming primarily involves hand milking or using parlor systems with herringbone, parallel, or rotary designs, emphasizing manual labor and regular routines. These methods require skilled workers to properly attach milking units and monitor milk quality, ensuring udder health and hygiene. Conventional practices also include timed milking schedules and maintenance of milking equipment to optimize milk yield and animal welfare.

Labor Efficiency: Automation vs Manual Operations

Robotic milking systems enhance labor efficiency by automating the entire milk harvesting process, reducing the need for manual labor and allowing farmers to reallocate time toward herd management and farm optimization. Conventional milking relies heavily on manual operations, requiring consistent labor input for tasks such as udder preparation, milking, and cleaning, which can increase labor costs and limit scalability. Automation in robotic milking improves consistency and throughput, resulting in higher productivity with fewer labor hours compared to traditional methods.

Animal Welfare and Cow Comfort Comparison

Robotic milking systems enhance animal welfare by allowing cows to be milked voluntarily, reducing stress and promoting natural milking behaviors, which improves udder health and overall comfort. Conventional milking often requires fixed schedules and human intervention, potentially causing increased stress and discomfort for the cows due to handling and restraint. Studies indicate that robotic milking can lead to higher milk yields and better recovery rates by prioritizing cow comfort and minimizing stress-related health issues.

Milk Yield and Quality: Robotic vs Conventional

Robotic milking systems consistently enhance milk yield by optimizing milking frequency and reducing cow stress, resulting in up to 10-15% higher production compared to conventional milking. Milk quality in robotic systems maintains superior consistency with lower somatic cell counts and reduced bacterial contamination due to automated cleaning and real-time monitoring. Conventional milking often faces variability in milk yield and quality related to manual handling and milking schedule limitations, impacting overall dairy farm efficiency.

Economic Analysis: Costs and Returns

Robotic milking systems significantly reduce labor costs by automating the milking process, leading to increased efficiency and higher milk yield per cow. Although initial investment and maintenance expenses for robotic systems are substantially higher compared to conventional milking, the long-term economic returns from improved milk quality and operational efficiency typically offset these costs. Conventional milking involves lower capital expenditure but incurs higher ongoing labor costs, resulting in a narrower profit margin under fluctuating milk prices.

Technological Integration and Farm Management

Robotic milking systems utilize advanced sensors and AI technology to automate milk harvesting, significantly enhancing precision and efficiency compared to conventional milking methods. These systems provide real-time data on milk yield, cow health, and milking frequency, enabling proactive farm management and improved animal welfare. Integration of robotic milking supports labor optimization and facilitates scalable dairy operations by reducing manual intervention and streamlining routine tasks.

Environmental Impact and Sustainability

Robotic milking systems reduce water usage by up to 30% and lower energy consumption compared to conventional milking parlors, contributing to decreased greenhouse gas emissions. Precision data monitoring in robotic milking enhances herd health management, minimizing antibiotic use and waste. These technologies promote sustainable dairy farming by improving resource efficiency and reducing environmental footprints.

Future Trends in Dairy Milking Techniques

Robotic milking systems are revolutionizing dairy farming by enhancing efficiency and animal welfare through automated, sensor-driven milk harvesting that operates 24/7 with minimal human intervention. Future trends emphasize integrating AI and IoT technologies to optimize milk yield, monitor cow health in real-time, and reduce labor costs compared to conventional milking methods. Advances in data analytics and machine learning algorithms are expected to further refine milking schedules and improve herd management, making robotic systems the preferred choice for sustainable dairy production.

Related Important Terms

Automated Teat Cleaning

Automated teat cleaning in robotic milking systems enhances udder health by reducing bacterial contamination through consistent, gentle cleaning cycles compared to manual methods in conventional milking. This technology improves milk quality and herd productivity by minimizing infections and optimizing milking efficiency.

Robotic Cluster Attachment

Robotic cluster attachment in dairy farming enhances milk harvesting efficiency by automating the teat detection and attachment process, reducing labor costs and minimizing cow stress compared to conventional milking methods. This technology improves milking consistency, maximizes milk yield, and allows for precise monitoring of udder health through integrated sensors.

Milking Parlor Throughput

Robotic milking systems enhance milking parlor throughput by enabling continuous, automated milking without the need for labor-intensive shifts, increasing daily milk harvest capacity by up to 30%. Conventional milking parlors rely on fixed schedules and manual labor, limiting throughput to predefined time slots and reducing overall efficiency compared to autonomous robotic units.

Liner Slip Detection

Robotic milking systems utilize advanced liner slip detection sensors to minimize milk contamination and optimize udder health by ensuring proper teat cup attachment, significantly reducing milking interruptions compared to conventional milking methods. Conventional milking relies heavily on manual observation, resulting in delayed slip detection that can increase teat damage and lower milk quality.

Real-Time Cow Identification

Robotic milking systems utilize advanced real-time cow identification technologies such as RFID tags and computer vision to accurately monitor and manage individual cows during milk harvesting, enhancing precision and animal welfare. Conventional milking relies on manual identification and batch processing, which can lead to delays and less personalized care, reducing overall efficiency in milk production.

Quarter Milking Sensors

Robotic milking systems equipped with advanced quarter milking sensors enable precise detection of milk flow and udder health in each quarter, enhancing milk quality and reducing mastitis risk compared to conventional milking methods. These sensors continuously monitor parameters such as milk conductivity and flow rate, allowing early identification of abnormalities and improving overall herd management efficiency.

Somatic Cell Count Monitoring (Automated)

Robotic milking systems utilize automated somatic cell count (SCC) monitoring to detect mastitis early, enhancing milk quality and reducing infection rates compared to conventional milking methods. These systems provide real-time SCC data, enabling precise herd health management and improving overall dairy productivity.

Precision Milk Yield Mapping

Robotic milking systems utilize advanced sensors and data analytics to achieve precision milk yield mapping, enabling farmers to monitor individual cow production and health in real-time with higher accuracy than conventional milking methods. This precision approach enhances milk quality control, optimizes herd management, and increases overall farm efficiency by providing detailed insights into yield variations and cow performance.

Cow Traffic Flow Optimization

Robotic milking systems optimize cow traffic flow by enabling voluntary milking schedules, reducing stress and labor costs while increasing milk yield through improved animal welfare. Conventional milking requires fixed milking times and manual movement of cows, often causing bottlenecks and inefficient herd management that can limit milk production.

Variable Frequency Pulsation

Variable Frequency Pulsation (VFP) in robotic milking systems enhances udder health and milk flow efficiency by dynamically adjusting stimulation rates to cow behavior, outperforming the fixed pulsation rates of conventional milking machines. This technology reduces teat-end stress and increases milking speed, leading to improved milk yield and animal welfare in automated dairy farming operations.

Robotic Milking vs Conventional Milking for Milk Harvesting Infographic

agridif.com

agridif.com