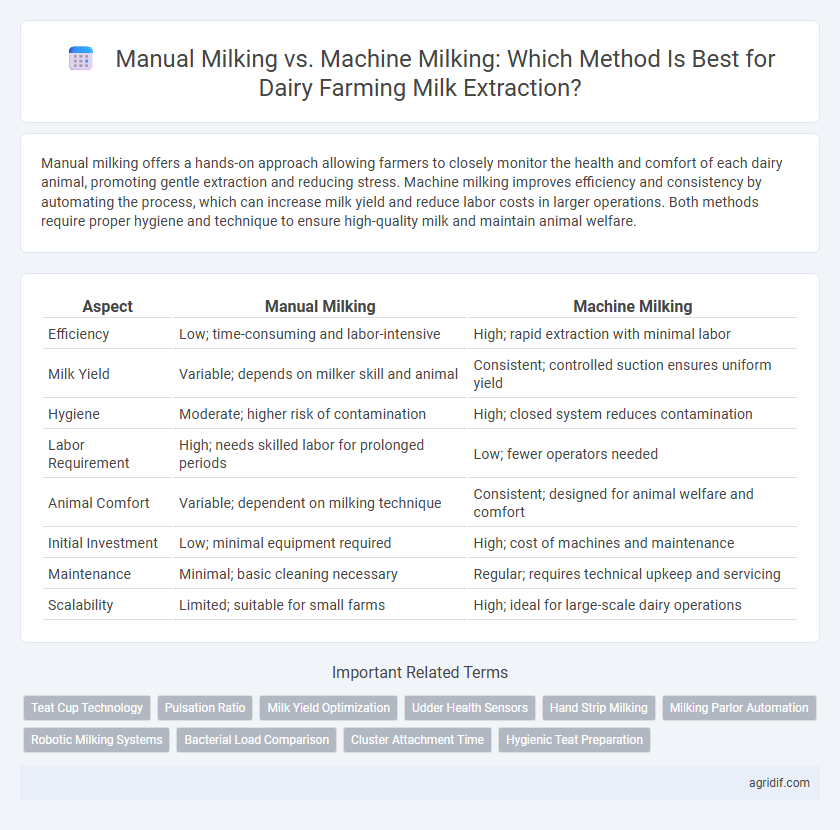

Manual milking offers a hands-on approach allowing farmers to closely monitor the health and comfort of each dairy animal, promoting gentle extraction and reducing stress. Machine milking improves efficiency and consistency by automating the process, which can increase milk yield and reduce labor costs in larger operations. Both methods require proper hygiene and technique to ensure high-quality milk and maintain animal welfare.

Table of Comparison

| Aspect | Manual Milking | Machine Milking |

|---|---|---|

| Efficiency | Low; time-consuming and labor-intensive | High; rapid extraction with minimal labor |

| Milk Yield | Variable; depends on milker skill and animal | Consistent; controlled suction ensures uniform yield |

| Hygiene | Moderate; higher risk of contamination | High; closed system reduces contamination |

| Labor Requirement | High; needs skilled labor for prolonged periods | Low; fewer operators needed |

| Animal Comfort | Variable; dependent on milking technique | Consistent; designed for animal welfare and comfort |

| Initial Investment | Low; minimal equipment required | High; cost of machines and maintenance |

| Maintenance | Minimal; basic cleaning necessary | Regular; requires technical upkeep and servicing |

| Scalability | Limited; suitable for small farms | High; ideal for large-scale dairy operations |

Introduction to Manual and Machine Milking

Manual milking involves extracting milk by hand, requiring skilled labor and offering full control over the process, while machine milking utilizes automated milking machines that improve efficiency and hygiene by reducing human contact. Manual milking is often preferred in small-scale dairy farms due to low initial costs, whereas machine milking suits large-scale operations by significantly increasing throughput and consistency. Understanding the benefits and limitations of both methods is crucial for optimizing milk quality, animal welfare, and farm productivity.

Overview of Manual Milking Techniques

Manual milking involves using hands to extract milk from the udder, applying rhythmic pressure to stimulate milk flow. Techniques such as the "strip" or "squeeze" method promote efficient milk let-down while minimizing teat injury and discomfort. Manual milking remains prevalent in small-scale dairy farms due to low initial costs and flexibility in handling individual cows.

How Milking Machines Work

Milking machines use vacuum pumps to create negative pressure around the cow's teats, gently extracting milk through a pulsation system that mimics the natural suckling action. Silicone liners within the teat cups open and close rhythmically, ensuring efficient milk flow while maintaining teat health and preventing injury. This automated process increases milking speed, improves hygiene by minimizing human contact, and enables consistent milk harvesting from multiple cows simultaneously.

Efficiency: Manual vs Machine Milking

Machine milking significantly enhances efficiency by allowing the extraction of milk from multiple cows simultaneously, reducing labor time compared to manual milking, which is slower and more labor-intensive. Automated milking systems increase daily milk yield by maintaining consistent milking intervals and minimizing human error while improving udder health through controlled vacuum and pulsation settings. In contrast, manual milking limits productivity due to variability in technique and physical fatigue, making machine milking the preferred choice for large-scale dairy operations aiming to optimize output and operational efficiency.

Impact on Milk Yield and Quality

Manual milking typically results in lower milk yield compared to machine milking due to inconsistent pressure and slower extraction rates, which can stress cows and reduce lactation efficiency. Machine milking ensures a more uniform and hygienic process, reducing contamination and preserving milk quality by minimizing bacterial exposure. However, improper machine use can cause teat damage, negatively affecting both milk yield and quality, highlighting the importance of proper maintenance and technique.

Animal Health Considerations

Manual milking allows for gentle handling, reducing the risk of teat injuries and mastitis, but it can be inconsistent and labor-intensive. Machine milking offers uniformity and efficiency, with automated cleaning systems minimizing bacterial contamination, yet improper machine settings may cause teat damage and stress. Regular maintenance and proper technique are crucial in both methods to ensure optimal udder health and prevent infections.

Labor Requirements and Cost Comparison

Manual milking demands significant labor hours and skilled hand techniques, leading to higher labor costs and slower milk extraction rates compared to machine milking. Machine milking systems require upfront investment in equipment but reduce ongoing labor expenses by automating the process, enhancing efficiency and consistency in milk yield. Cost analysis shows that machine milking lowers overall operational costs over time despite initial capital outlay, making it economically favorable for larger dairy farms.

Hygiene and Contamination Risks

Manual milking increases the risk of contamination due to direct human contact, which can introduce bacteria and pathogens if proper hygiene practices are not strictly followed. Machine milking systems offer better control over hygiene by using sterilized equipment and automated cleaning processes, reducing bacterial contamination and improving milk quality. Consistent maintenance and sanitation protocols for milking machines are essential to prevent biofilm formation and ensure milk safety in dairy farming operations.

Suitability for Small vs Large Scale Dairy Farms

Manual milking remains suitable for small-scale dairy farms due to its low initial investment and ease of implementation, supporting close animal interaction and health monitoring. Machine milking optimizes efficiency and consistency, making it ideal for large-scale dairy operations with high milk yield demands and labor cost reduction priorities. Both methods impact overall productivity and animal welfare, influencing farm scale decisions based on economic and operational factors.

Future Trends in Milking Technology

Emerging trends in milking technology emphasize automation and precision through advanced sensor integration and robotic systems, enabling real-time monitoring of milk quality and cow health. Machine milking is increasingly favored for its efficiency, consistency, and ability to reduce labor costs, while evolving designs aim to enhance animal welfare and minimize stress during extraction. The future of dairy farming is likely to involve smart milking parlors leveraging artificial intelligence and the Internet of Things (IoT) to optimize herd management and maximize milk yield.

Related Important Terms

Teat Cup Technology

Teat cup technology in machine milking enhances milk extraction efficiency by using vacuum systems that simulate natural suckling, reducing teat damage compared to manual milking. Automated teat cups ensure consistent milking speed and pressure, improving udder health and increasing overall milk yield in dairy farming operations.

Pulsation Ratio

Manual milking relies on the natural rhythm of the milk letdown reflex, often resulting in an inconsistent pulsation ratio that can affect milk flow and udder health. Machine milking systems maintain a precise pulsation ratio, typically around 60:40 or 65:35 (milking to rest phase), optimizing milk extraction efficiency while minimizing teat tissue damage.

Milk Yield Optimization

Machine milking enhances milk yield optimization by providing consistent milking intervals, reducing udder stress, and improving hygiene, leading to higher milk output compared to manual milking. Manual milking, while cost-effective for small herds, generally results in lower efficiency and inconsistent milk extraction, impacting overall production levels.

Udder Health Sensors

Udder health sensors integrated with machine milking systems provide real-time monitoring of milk quality, detecting early signs of mastitis and reducing infection rates compared to manual milking. These sensors optimize milk yield and improve dairy herd health management by accurately tracking udder temperature, conductivity, and milk flow.

Hand Strip Milking

Hand strip milking, a traditional manual milking method, offers precise control over milk extraction and reduces the risk of teat damage associated with improper machine use. This technique enhances udder stimulation, promoting better milk let-down while maintaining hygiene through direct farmer oversight.

Milking Parlor Automation

Milking parlor automation significantly enhances milk extraction efficiency compared to manual milking by reducing labor costs and increasing milking speed with consistent quality. Automated systems employ advanced technologies such as robotic arms, sensors, and real-time data monitoring to improve udder health and optimize milk yield.

Robotic Milking Systems

Robotic milking systems enhance milk extraction efficiency by automating the process with precision sensors and AI-driven teat detection, significantly reducing labor costs and improving animal welfare compared to manual milking. These systems provide real-time data on milk yield and cow health, enabling proactive herd management and higher overall productivity on dairy farms.

Bacterial Load Comparison

Manual milking exposes milk to higher bacterial loads due to increased contact with hands and environmental contaminants compared to machine milking, which utilizes sanitized equipment to minimize microbial contamination. Studies indicate that machine milking significantly reduces the presence of pathogens like Staphylococcus aureus and Escherichia coli, enhancing milk hygiene and safety.

Cluster Attachment Time

Manual milking typically involves longer cluster attachment times due to the slower and less consistent process, which can increase the risk of teat-end damage and reduce milking efficiency. Machine milking optimizes cluster attachment time with automated systems that ensure consistent suction and milking speed, enhancing milk yield and teat health.

Hygienic Teat Preparation

Hygienic teat preparation in manual milking involves thorough cleaning and drying of each teat to prevent bacterial contamination, ensuring higher milk quality and udder health. Machine milking incorporates automated teat cleaning systems that standardize hygiene practices, reducing the risk of mastitis and improving overall milk safety.

Manual milking vs Machine milking for milk extraction Infographic

agridif.com

agridif.com