Pasteurization and homogenization are essential processes in dairy farming pet milk production, each serving distinct purposes to ensure safety and quality. Pasteurization involves heating milk to destroy harmful bacteria and pathogens, enhancing the safety for pet consumption. Homogenization mechanically breaks down fat molecules to create a uniform texture, preventing cream separation and improving the milk's consistency for easier digestion by pets.

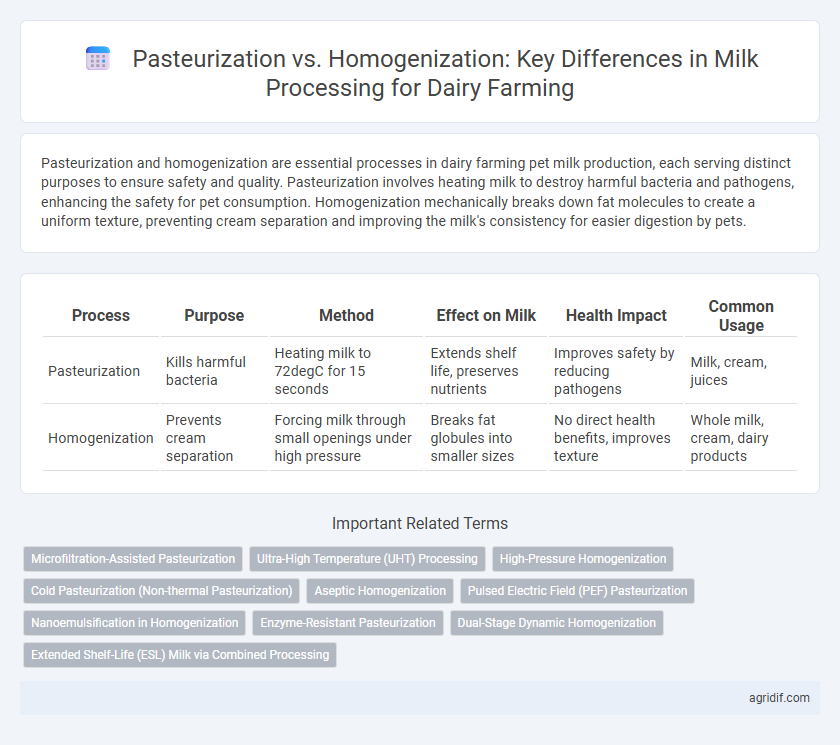

Table of Comparison

| Process | Purpose | Method | Effect on Milk | Health Impact | Common Usage |

|---|---|---|---|---|---|

| Pasteurization | Kills harmful bacteria | Heating milk to 72degC for 15 seconds | Extends shelf life, preserves nutrients | Improves safety by reducing pathogens | Milk, cream, juices |

| Homogenization | Prevents cream separation | Forcing milk through small openings under high pressure | Breaks fat globules into smaller sizes | No direct health benefits, improves texture | Whole milk, cream, dairy products |

Understanding Pasteurization in Dairy Farming

Pasteurization in dairy farming involves heating milk to a specific temperature, typically 72degC (161degF) for 15 seconds, to eliminate harmful pathogens and extend shelf life while preserving nutritional value. This process significantly reduces the risk of diseases such as tuberculosis and listeriosis, ensuring milk safety for consumers. Unlike homogenization, which mechanically breaks down fat globules for consistent texture, pasteurization primarily targets microbial safety without altering milk's natural fat structure.

What Is Homogenization in Milk Processing?

Homogenization in milk processing is a mechanical treatment that breaks down fat globules into smaller, uniform sizes, preventing cream from separating and rising to the top. This process enhances milk's texture, stability, and taste by creating a consistent, smooth product. Unlike pasteurization, which uses heat to kill harmful bacteria, homogenization focuses solely on improving the physical properties of milk for better consumer appeal.

Key Differences Between Pasteurization and Homogenization

Pasteurization is a heat treatment process aimed at killing harmful bacteria and extending milk's shelf life, typically heated to 72degC for 15 seconds. Homogenization mechanically breaks down fat molecules to prevent cream separation, resulting in a uniform texture and smoother milk. While pasteurization ensures safety by reducing microbial content, homogenization improves milk's consistency and mouthfeel without affecting its microbial quality.

Importance of Pasteurization for Milk Safety

Pasteurization is essential in dairy farming for eliminating harmful pathogens such as Salmonella, Listeria, and E. coli from milk, ensuring consumer safety. This heat treatment process significantly reduces the risk of milk-borne illnesses without compromising nutritional quality. Unlike homogenization, which improves milk texture by breaking down fat molecules, pasteurization is critical for meeting food safety standards and protecting public health.

The Role of Homogenization in Milk Texture

Homogenization plays a crucial role in milk processing by breaking down fat globules into smaller, uniformly distributed particles, which prevents cream separation and creates a smoother, creamier texture. This mechanical process enhances the sensory properties of milk, making it more appealing to consumers by improving mouthfeel and consistency. In contrast to pasteurization, which targets microbial safety, homogenization primarily focuses on altering milk's physical characteristics for better texture and stability.

Health Benefits: Pasteurized vs Homogenized Milk

Pasteurization kills harmful bacteria in milk, significantly reducing the risk of foodborne illnesses and improving overall safety for consumption. Homogenization, on the other hand, breaks down fat molecules to create a uniform texture but does not affect microbial content or kill pathogens. Choosing pasteurized milk offers critical health benefits by ensuring microbiological safety, while homogenized milk mainly enhances taste and mouthfeel without altering health risks.

Impacts on Nutritional Value: Pasteurization and Homogenization

Pasteurization significantly reduces harmful bacteria in milk by heating it to at least 161degF (72degC) for 15 seconds, preserving most vitamins like A and D but slightly decreasing vitamin C levels. Homogenization mechanically breaks fat molecules to create a uniform texture, enhancing digestibility without altering the milk's inherent nutritional content. Both processes are essential for safety and taste, with minimal impact on milk's core nutrients such as calcium, protein, and essential fatty acids.

Effects on Milk Shelf Life and Quality

Pasteurization extends milk shelf life by eliminating harmful bacteria, ensuring safety without significantly impacting flavor or nutritional value. Homogenization improves milk quality by breaking down fat globules, creating a smoother texture and preventing cream separation, but it does not prolong shelf life. Combining both processes results in milk that is safer, more consistent in quality, and has an extended shelf life suitable for consumer markets.

Technological Advances in Milk Processing

Advancements in milk processing technology have enhanced both pasteurization and homogenization methods to improve milk safety and quality. Pasteurization uses precise heat treatments such as high-temperature short-time (HTST) and ultra-high temperature (UHT) processing to eliminate pathogens while preserving nutrients. Homogenization employs high-pressure mechanical forces to break fat globules into uniform sizes, preventing cream separation and improving texture and shelf life in modern dairy production.

Choosing the Right Milk Processing Method for Dairy Farms

Pasteurization effectively eliminates harmful bacteria in milk by heating it to specific temperatures, ensuring safety and extending shelf life, while homogenization mechanically breaks down fat globules to create a uniform texture and prevent cream separation. Dairy farms must evaluate their production goals and consumer preferences when choosing between these methods, prioritizing pasteurization for safety and homogenization for consistency. Integrating both processes can optimize milk quality, meeting health standards and market demands in diverse dairy product lines.

Related Important Terms

Microfiltration-Assisted Pasteurization

Microfiltration-assisted pasteurization enhances milk safety by combining membrane filtration with heat treatment, effectively reducing microbial load while preserving nutritional quality. This process offers a superior alternative to traditional homogenization by maintaining milk's natural fat globule structure and improving shelf life without mechanical fat breakdown.

Ultra-High Temperature (UHT) Processing

Ultra-High Temperature (UHT) processing sterilizes milk by heating it above 135degC for a few seconds, effectively destroying all microorganisms and spores without refrigeration, unlike traditional pasteurization which only reduces microbial load. Homogenization, often combined with UHT, mechanically breaks down fat globules to ensure a uniform texture and prevent cream separation, enhancing shelf life and consumer acceptance in dairy products.

High-Pressure Homogenization

High-Pressure Homogenization (HPH) significantly enhances milk quality by breaking down fat globules into smaller, uniform sizes, improving texture and shelf life without heat damage associated with pasteurization. Unlike traditional pasteurization that primarily targets microbial reduction through heat, HPH maintains nutritional value and sensory attributes while ensuring microbial safety through mechanical disruption.

Cold Pasteurization (Non-thermal Pasteurization)

Cold pasteurization, also known as non-thermal pasteurization, uses techniques such as high-pressure processing (HPP) or ultraviolet (UV) light to eliminate pathogens in milk without heat, preserving nutrients and flavor better than traditional thermal pasteurization. Unlike homogenization, which mechanically breaks down fat molecules to improve milk texture and prevent cream separation, cold pasteurization focuses on microbial safety while maintaining the milk's natural composition.

Aseptic Homogenization

Aseptic homogenization in milk processing combines sterilization and homogenization in a sterile environment, ensuring extended shelf life and improved safety by eliminating microbial contamination. Unlike pasteurization, which only heats milk to destroy pathogens, aseptic homogenization maintains milk's freshness and texture while enabling long-term storage without refrigeration.

Pulsed Electric Field (PEF) Pasteurization

Pulsed Electric Field (PEF) pasteurization offers a non-thermal alternative to traditional heat-based methods, effectively inactivating pathogens while preserving milk's nutritional and sensory qualities. Unlike homogenization, which mechanically breaks fat globules to improve texture, PEF targets microbial safety without altering milk's physical properties, enhancing dairy farming product quality and shelf life.

Nanoemulsification in Homogenization

Pasteurization eliminates harmful pathogens in milk through controlled heat treatment, ensuring safety without altering its nutritional value, while homogenization breaks down fat molecules into nanoscale emulsions, creating a uniform texture and preventing cream separation. Nanoemulsification in homogenization enhances milk's stability and digestibility by producing ultra-fine fat droplets that improve bioavailability and shelf life.

Enzyme-Resistant Pasteurization

Enzyme-resistant pasteurization involves heating milk to a specific temperature that kills harmful pathogens while preserving beneficial enzymes, enhancing nutritional value and extending shelf life. Unlike homogenization, which mechanically breaks down fat molecules to create a uniform texture, enzyme-resistant pasteurization focuses on maintaining milk's natural enzyme activity for improved digestive and health benefits.

Dual-Stage Dynamic Homogenization

Dual-stage dynamic homogenization enhances milk processing by breaking fat globules into uniform sizes, improving texture and stability without altering nutritional content, unlike pasteurization which primarily targets pathogen elimination through heat treatment. This method optimizes milk's sensory qualities and shelf life, supporting efficient dairy production while maintaining safety standards.

Extended Shelf-Life (ESL) Milk via Combined Processing

Extended Shelf-Life (ESL) milk achieves prolonged freshness through the combined processing of pasteurization and homogenization, which together eliminate pathogens and evenly disperse fat globules for improved stability. This integrated approach enhances microbial safety and prevents cream separation, significantly extending milk's shelf life beyond traditional methods.

Pasteurization vs Homogenization for milk processing Infographic

agridif.com

agridif.com