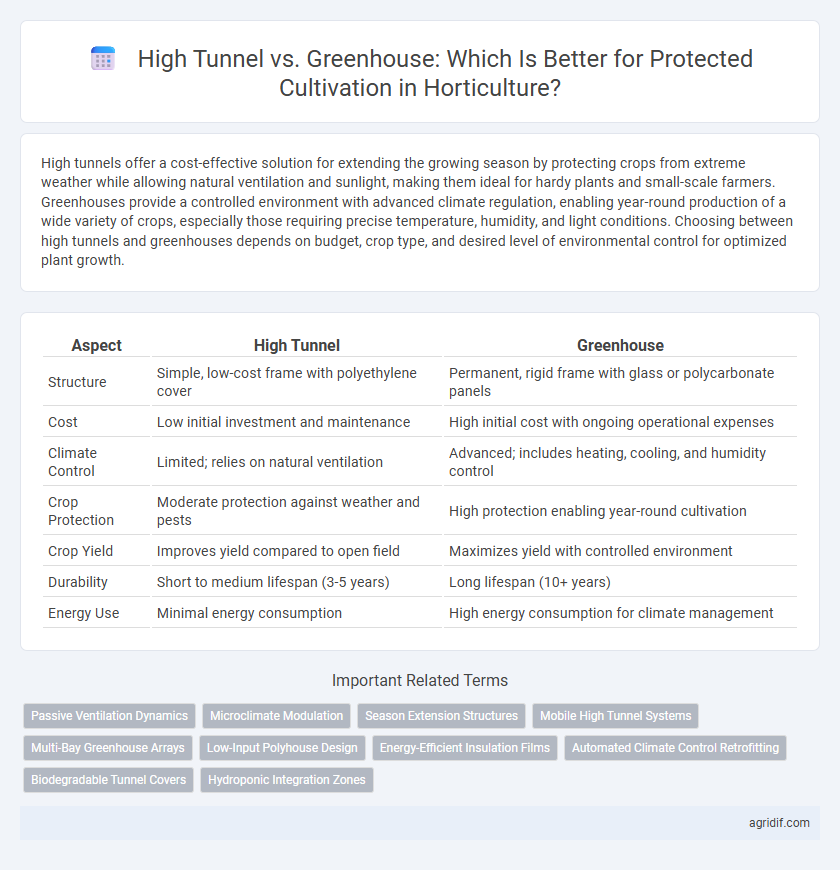

High tunnels offer a cost-effective solution for extending the growing season by protecting crops from extreme weather while allowing natural ventilation and sunlight, making them ideal for hardy plants and small-scale farmers. Greenhouses provide a controlled environment with advanced climate regulation, enabling year-round production of a wide variety of crops, especially those requiring precise temperature, humidity, and light conditions. Choosing between high tunnels and greenhouses depends on budget, crop type, and desired level of environmental control for optimized plant growth.

Table of Comparison

| Aspect | High Tunnel | Greenhouse |

|---|---|---|

| Structure | Simple, low-cost frame with polyethylene cover | Permanent, rigid frame with glass or polycarbonate panels |

| Cost | Low initial investment and maintenance | High initial cost with ongoing operational expenses |

| Climate Control | Limited; relies on natural ventilation | Advanced; includes heating, cooling, and humidity control |

| Crop Protection | Moderate protection against weather and pests | High protection enabling year-round cultivation |

| Crop Yield | Improves yield compared to open field | Maximizes yield with controlled environment |

| Durability | Short to medium lifespan (3-5 years) | Long lifespan (10+ years) |

| Energy Use | Minimal energy consumption | High energy consumption for climate management |

Introduction to Protected Cultivation in Horticulture

Protected cultivation in horticulture enhances crop productivity and extends growing seasons by creating controlled environments. High tunnels, constructed with metal frames and polyethylene covers, offer cost-effective, passive protection primarily from weather extremes. Greenhouses provide a more sophisticated environment with glass or rigid plastic panels and integrated climate controls, allowing precise regulation of temperature, humidity, and light for optimized plant growth.

High Tunnels vs Greenhouses: Defining Both Systems

High tunnels are unheated, polyethylene-covered structures that extend the growing season by protecting crops from wind, rain, and frost while relying on natural sunlight for plant growth. Greenhouses are fully enclosed structures with controlled temperature, humidity, and light systems that enable year-round crop production and precise environmental management. Both systems enhance protected cultivation, but high tunnels offer cost-effective seasonal protection, whereas greenhouses provide advanced climate control for optimal crop yields.

Structural Differences: High Tunnel and Greenhouse Designs

High tunnels typically feature simple, low-cost hoop structures with polyethylene covers, allowing natural ventilation through sidewalls, while greenhouses use rigid frames made of aluminum or steel combined with glass or polycarbonate panels for controlled environments. The structural design of greenhouses includes advanced systems for temperature, humidity, and light control, enabling year-round cultivation, whereas high tunnels rely more on passive climate regulation suited for seasonal use. These design differences directly impact crop protection, growth cycles, and environmental management in protected cultivation.

Climate Control Capabilities: Temperature and Humidity Management

High tunnels offer cost-effective temperature regulation through passive solar heating and ventilation but lack precise climate control systems found in greenhouses. Greenhouses enable advanced temperature and humidity management using automated HVAC systems, shading, and misting technologies, optimizing plant growth conditions year-round. Efficient climate control in greenhouses reduces crop stress and enhances yield quality compared to the more variable environment inside high tunnels.

Crop Suitability for High Tunnels and Greenhouses

High tunnels are ideal for crops like tomatoes, peppers, and leafy greens that require moderate temperature control and ventilation, promoting faster growth during cooler seasons. Greenhouses provide more precise environmental regulation, making them suitable for sensitive crops such as orchids, cucumbers, and strawberries that demand consistent humidity, temperature, and light levels. Crop selection should consider the thermal insulation properties and microclimate stability offered by each structure to maximize yield and quality.

Cost Analysis: Investment and Operating Expenses

High tunnels generally require lower initial investment costs, typically ranging from $2 to $6 per square foot, compared to greenhouses, which can exceed $15 per square foot due to more complex structures and materials. Operating expenses for high tunnels are minimal since they rely mainly on passive solar heating and natural ventilation, while greenhouses incur higher energy costs for heating, cooling, and humidity control systems. Long-term cost analysis shows high tunnels offer cost-effective protected cultivation for small- to medium-scale growers, whereas greenhouses provide superior environmental control suitable for high-value crops despite increased operating expenses.

Yield and Productivity Comparison

High tunnels typically offer higher yield per square foot due to lower construction costs and better ventilation, enabling more efficient crop growth cycles. Greenhouses provide superior environmental control, enhancing year-round productivity but often at increased operational and energy expenses. Choosing between high tunnels and greenhouses depends on balancing yield goals with budget constraints and climate conditions.

Pest and Disease Management in Protected Systems

High tunnels offer superior ventilation and reduced humidity levels, which significantly lower the risk of fungal diseases compared to traditional greenhouses. Greenhouses, while providing controlled environments for year-round cultivation, often require integrated pest management strategies to combat higher moisture levels that favor pest proliferation. Effective pest and disease management in both systems relies on monitoring, maintaining optimal airflow, and selecting disease-resistant crop varieties tailored to the protected cultivation environment.

Sustainability and Resource Use Efficiency

High tunnels offer a low-cost, energy-efficient alternative to greenhouses by utilizing passive solar energy and natural ventilation, significantly reducing the need for supplemental heating and cooling. Greenhouses provide more controlled environments with advanced climate regulation, but often require higher energy inputs, impacting sustainability and resource use efficiency. Selecting between high tunnels and greenhouses depends on crop requirements, budget constraints, and the goal of minimizing environmental footprint through efficient water, energy, and material utilization.

Choosing the Right Structure: Factors Influencing Farmer Decisions

Farmers choosing between high tunnels and greenhouses for protected cultivation consider factors such as initial investment costs, climate control capabilities, and crop type compatibility. High tunnels provide cost-effective season extension with natural ventilation, while greenhouses offer precise environmental control for year-round production. Decision-making also hinges on farm size, maintenance requirements, and desired crop yield and quality.

Related Important Terms

Passive Ventilation Dynamics

High tunnels rely on naturally occurring wind and temperature gradients for passive ventilation, using sidewalls and endwalls that can be manually or automatically rolled up to regulate airflow and temperature, making them energy-efficient for season extension. In contrast, greenhouses often incorporate more controlled ventilation systems such as roof vents and mechanical fans, allowing precise climate management but increasing energy consumption and operational complexity in protected cultivation.

Microclimate Modulation

High tunnels provide effective microclimate modulation by enhancing temperature control and ventilation through passive methods, which reduces energy costs compared to greenhouses. Greenhouses offer precise environmental regulation with automated heating, cooling, and humidity control systems, optimizing plant growth conditions but at a higher operational expense.

Season Extension Structures

High tunnels offer cost-effective season extension by providing frost protection and enhanced microclimate control, enabling earlier planting and later harvesting compared to open fields. Greenhouses provide a more controlled environment with superior temperature, humidity, and pest management, allowing year-round cultivation but requiring higher initial investment and operational costs.

Mobile High Tunnel Systems

Mobile high tunnel systems offer flexibility in protected cultivation by allowing growers to move structures seasonally, optimizing sunlight exposure and crop rotation compared to fixed-location greenhouses. These movable tunnels reduce soil-borne disease risks and lower initial investment costs while maintaining controlled environments that enhance plant growth and extend production seasons.

Multi-Bay Greenhouse Arrays

Multi-bay greenhouse arrays offer enhanced environmental control and extended growing seasons compared to high tunnels, allowing for precise temperature, humidity, and light regulation critical for high-value horticultural crops. These structures facilitate scalable production with improved pest management and energy efficiency, optimizing crop yield and quality in protected cultivation systems.

Low-Input Polyhouse Design

High tunnels offer cost-effective, low-input solutions for protected cultivation by using simple polyethylene covers and passive ventilation, optimizing microclimates for crop growth with minimal energy requirements. Compared to high-cost greenhouses, high tunnels reduce initial investment and operational complexity while providing adequate protection from environmental stressors in polyhouse design.

Energy-Efficient Insulation Films

High tunnel structures utilize single-layer polyethylene films that offer cost-effective insulation but limited energy efficiency compared to multi-layer greenhouse films designed with advanced thermal barriers and UV stabilization. Energy-efficient insulation films for greenhouses significantly reduce heat loss, enhance daytime solar gain, and optimize microclimate control, thereby improving crop yield and reducing heating energy demand by up to 30%.

Automated Climate Control Retrofitting

High tunnels provide a cost-effective, passive environment but lack integrated automated climate control, making retrofitting with sensors and ventilation systems essential for precision management. In contrast, greenhouses are designed for automated climate control from installation, offering advanced technologies like automated shading, heating, and humidity regulation that can be upgraded with IoT-enabled devices for enhanced protection and yield optimization.

Biodegradable Tunnel Covers

Biodegradable tunnel covers for high tunnels offer sustainable alternatives to traditional polyethylene films, reducing plastic waste while providing effective temperature and humidity control for crops. Compared to greenhouses, high tunnels with biodegradable covers deliver cost-efficient protection and improved soil health by facilitating natural degradation and minimizing environmental impact.

Hydroponic Integration Zones

High tunnels offer cost-effective, controlled environments primarily suited for soil-based hydroponic integration due to their simplicity and natural ventilation, while greenhouses provide advanced climate control systems essential for optimizing hydroponic zones requiring precise temperature, humidity, and light management. Choosing between high tunnel and greenhouse structures depends on the scale of hydroponic production, crop sensitivity, and the requirement for automated environmental controls.

High Tunnel vs Greenhouse for Protected Cultivation Infographic

agridif.com

agridif.com