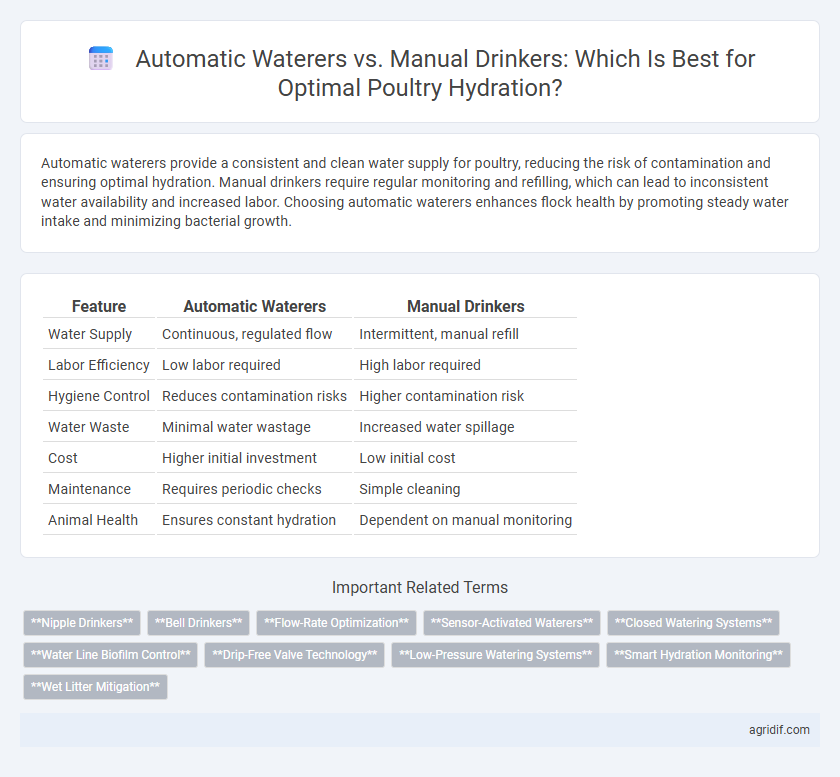

Automatic waterers provide a consistent and clean water supply for poultry, reducing the risk of contamination and ensuring optimal hydration. Manual drinkers require regular monitoring and refilling, which can lead to inconsistent water availability and increased labor. Choosing automatic waterers enhances flock health by promoting steady water intake and minimizing bacterial growth.

Table of Comparison

| Feature | Automatic Waterers | Manual Drinkers |

|---|---|---|

| Water Supply | Continuous, regulated flow | Intermittent, manual refill |

| Labor Efficiency | Low labor required | High labor required |

| Hygiene Control | Reduces contamination risks | Higher contamination risk |

| Water Waste | Minimal water wastage | Increased water spillage |

| Cost | Higher initial investment | Low initial cost |

| Maintenance | Requires periodic checks | Simple cleaning |

| Animal Health | Ensures constant hydration | Dependent on manual monitoring |

Introduction to Poultry Hydration Solutions

Automatic waterers provide consistent water supply with minimal labor, reducing contamination risks and ensuring better hydration for poultry. Manual drinkers require regular refilling and monitoring, which can increase labor costs and potential stress on birds due to inconsistent water availability. Choosing between automatic and manual systems impacts flock health, growth rates, and farm efficiency in poultry hydration management.

Understanding Automatic Waterers

Automatic waterers provide consistent, clean hydration by maintaining a steady water level, minimizing contamination risks common in manual drinkers. These systems reduce labor and water wastage while promoting optimal poultry health and growth rates. Integration of automatic waterers enhances farm efficiency and supports high-density poultry operations.

Overview of Manual Drinkers

Manual drinkers in poultry farming provide a cost-effective hydration solution requiring minimal infrastructure and maintenance, often using simple designs like nipple or trough systems. These drinkers depend on regular manual refilling and monitoring to ensure consistent water availability and prevent contamination. Although less automated, manual drinkers facilitate control over water quality and reduce the risk of leaks or mechanical failures common in automatic watering systems.

Installation and Setup Differences

Automatic waterers in poultry farming require a connection to a water supply system and often involve pressure regulation devices, making installation more complex but consistent in water delivery. Manual drinkers, usually simple nipples or troughs, demand minimal setup, requiring only placement and routine refilling, resulting in lower initial installation time and cost. Choosing between the two depends on the scale of the operation and desired labor efficiency, with automatic systems favoring larger farms for ease of maintenance and manual drinkers suiting smaller setups.

Maintenance and Cleaning Requirements

Automatic waterers in poultry farming offer reduced maintenance with self-regulating water flow and fewer contamination risks, requiring periodic checks to ensure cleanliness and functionality. Manual drinkers demand frequent refilling and thorough cleaning to prevent algae buildup and bacterial growth, increasing labor intensity. Regular sanitization of either system is crucial to maintain optimal hydration and poultry health.

Water Quality and Contamination Risks

Automatic waterers provide a consistent flow of clean water, reducing the risk of contamination from bacteria and algae buildup commonly found in stagnant water of manual drinkers. These systems often include filtration features that maintain higher water quality by preventing debris and pathogens from entering the poultry's drinking source. In contrast, manual drinkers require frequent cleaning and monitoring to avoid contamination, which can lead to decreased hydration and increased disease risk in poultry flocks.

Cost Comparison: Upfront and Long-Term

Automatic waterers typically require higher initial investment ranging from $50 to $200 per unit, while manual drinkers cost between $10 and $30. Over time, automatic systems reduce labor costs and water waste, potentially saving up to 30% annually in operational expenses. Manual drinkers incur ongoing labor hours and increased water spillage, leading to higher long-term costs despite lower upfront pricing.

Labor Efficiency and Time Management

Automatic waterers in poultry farming significantly enhance labor efficiency by reducing the need for frequent manual refilling, allowing farmers to allocate time to other critical tasks. These systems maintain consistent water availability, minimizing downtime and preventing dehydration-related growth issues in poultry. Manual drinkers, while cost-effective initially, demand constant monitoring and refilling, increasing labor hours and potentially compromising time management on larger farms.

Impact on Flock Health and Productivity

Automatic waterers provide consistent and clean water access, significantly reducing the risk of bacterial contamination and dehydration in poultry flocks. This steady hydration supports optimal digestion, growth rates, and egg production, enhancing overall flock productivity and health outcomes. Manual drinkers often lead to fluctuating water availability, increasing stress and susceptibility to diseases, which can negatively impact flock performance.

Choosing the Best Hydration System for Your Flock

Automatic waterers provide consistent and clean water supply, reducing labor and minimizing contamination risks compared to manual drinkers. Manual drinkers require regular cleaning and refilling, potentially leading to inconsistent hydration and increased disease risk. Selecting the best hydration system depends on flock size, farm management style, and budget, with automatic systems favored for large operations due to efficiency and water conservation.

Related Important Terms

Nipple Drinkers

Nipple drinkers in poultry farming provide precise water delivery, reducing spillage and contamination risks, which promotes better hygiene and prevents water wastage compared to manual drinkers. Their automatic operation ensures consistent hydration tailored to birds' needs, enhancing growth rates and minimizing labor effort in large-scale poultry operations.

Bell Drinkers

Bell drinkers in poultry farming offer consistent water delivery and reduce spillage compared to manual drinkers, enhancing sanitation and minimizing water waste. Their automatic mechanism adjusts to flock size and activity, ensuring efficient hydration and promoting better overall flock health.

Flow-Rate Optimization

Automatic waterers in poultry farming provide precise flow-rate optimization, ensuring consistent hydration by delivering water at regulated speeds that prevent wastage and reduce spillages. Manual drinkers often lack this control, leading to irregular flow rates that can cause dehydration stress or excessive water consumption among birds.

Sensor-Activated Waterers

Sensor-activated waterers provide precise hydration management in poultry farming by automatically detecting when birds need water, reducing wastage and contamination compared to manual drinkers. These systems enhance bird health and growth rates through consistent water availability and improved hygiene, leading to higher overall farm productivity.

Closed Watering Systems

Closed watering systems in poultry farming ensure consistent hydration by minimizing contamination and water spillage, improving bird health and reducing water waste compared to manual drinkers. Automatic waterers in these systems maintain optimal water pressure and hygiene, reducing labor costs and enhancing overall farm biosecurity.

Water Line Biofilm Control

Automatic waterers minimize biofilm buildup by providing a constant flow of fresh water and reducing stagnant zones, which inhibits bacterial growth in poultry water lines. Manual drinkers often require frequent cleaning and maintenance to control biofilm formation, as water stagnation encourages microbial buildup that can compromise bird health.

Drip-Free Valve Technology

Automatic waterers with drip-free valve technology significantly reduce water wastage by preventing leaks and spills, ensuring consistent hydration for poultry while maintaining dry litter conditions. This advanced system enhances biosecurity and lowers labor costs compared to manual drinkers, which often require frequent monitoring and adjustment to avoid water contamination and wastage.

Low-Pressure Watering Systems

Low-pressure watering systems in poultry farming offer consistent water flow through automatic waterers, reducing spillage and contamination risks compared to manual drinkers. These systems enhance bird hydration efficiency by maintaining optimal water pressure, promoting better health and growth rates in poultry flocks.

Smart Hydration Monitoring

Smart hydration monitoring in poultry farming enhances water consumption accuracy by integrating sensors in automatic waterers to track real-time intake and detect abnormalities in flock hydration. Manual drinkers lack this technology, leading to potential under- or over-hydration without immediate data feedback, impacting bird health and production efficiency.

Wet Litter Mitigation

Automatic waterers in poultry farming significantly reduce wet litter by providing controlled water flow and minimizing spillage, which helps maintain drier bedding and lowers the risk of ammonia build-up and footpad dermatitis. In contrast, manual drinkers often lead to inconsistent water delivery and increased dripping, resulting in wetter litter conditions that can compromise bird health and farm sanitation.

Automatic Waterers vs Manual Drinkers for hydration Infographic

agridif.com

agridif.com