Floor feeding in poultry farming offers natural foraging behavior and reduces feed wastage but may increase contamination risks and uneven distribution. Pan feeding ensures controlled portions, cleaner feed, and easier management, promoting uniform growth and reducing disease spread. Choosing between these methods depends on flock size, housing conditions, and hygiene priorities.

Table of Comparison

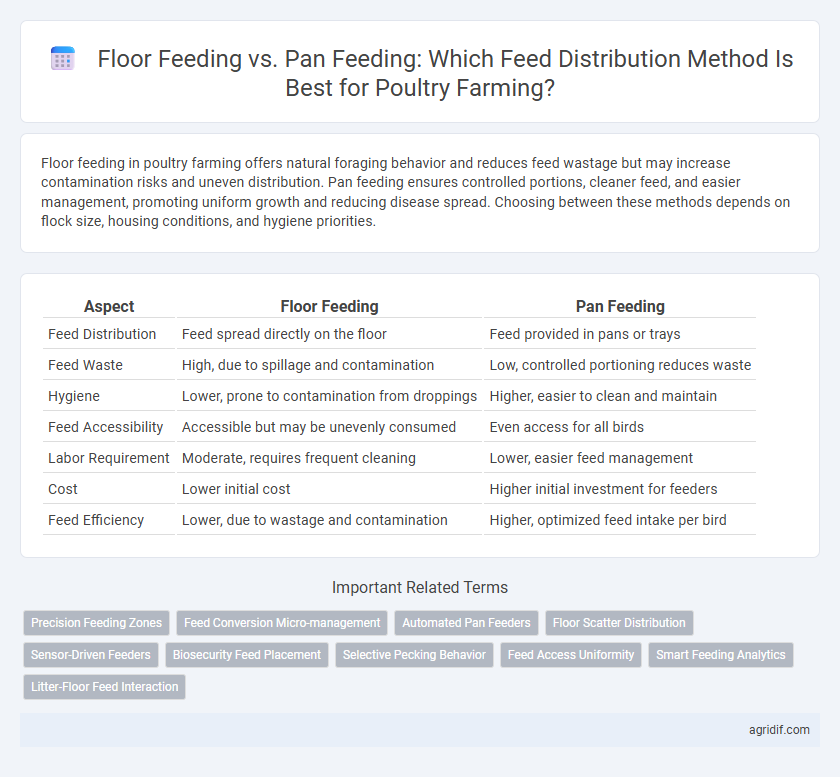

| Aspect | Floor Feeding | Pan Feeding |

|---|---|---|

| Feed Distribution | Feed spread directly on the floor | Feed provided in pans or trays |

| Feed Waste | High, due to spillage and contamination | Low, controlled portioning reduces waste |

| Hygiene | Lower, prone to contamination from droppings | Higher, easier to clean and maintain |

| Feed Accessibility | Accessible but may be unevenly consumed | Even access for all birds |

| Labor Requirement | Moderate, requires frequent cleaning | Lower, easier feed management |

| Cost | Lower initial cost | Higher initial investment for feeders |

| Feed Efficiency | Lower, due to wastage and contamination | Higher, optimized feed intake per bird |

Introduction to Poultry Feed Distribution Methods

Floor feeding and pan feeding represent two primary methods of feed distribution in poultry farming, each impacting feed accessibility and waste differently. Floor feeding involves spreading feed directly on the poultry house floor, promoting natural foraging behavior but often leading to increased spillage and contamination. Pan feeding utilizes shallow containers to deliver feed, reducing waste and improving feed hygiene, thereby enhancing growth performance and feed conversion ratios in poultry flocks.

What is Floor Feeding in Poultry Farming?

Floor feeding in poultry farming involves spreading feed directly on the barn or house floor, allowing birds to peck and consume feed naturally. This method promotes uniform feed distribution and reduces overcrowding around feeders, supporting natural foraging behavior and minimizing feed wastage. Floor feeding is particularly beneficial in free-range and large-scale operations where maximizing bird access to feed is essential for optimal growth and health.

Understanding Pan Feeding Systems

Pan feeding systems in poultry farming offer precise feed distribution by delivering measured amounts of feed directly to birds, reducing waste compared to floor feeding methods. These systems promote uniform feed access, encouraging consistent growth and minimizing feed contamination risks from litter and droppings. The efficiency of pan feeders improves feed conversion ratios and supports better flock health management through controlled feeding environments.

Comparing Feed Distribution Efficiency

Floor feeding distributes feed broadly across the poultry house floor, allowing multiple birds simultaneous access but often results in higher feed wastage due to spillage and contamination. Pan feeding concentrates feed in designated containers, promoting controlled portions and reducing waste while ensuring consistent feed intake among birds. Efficiency in feed distribution improves with pan feeding by minimizing feed loss and optimizing nutrient utilization, leading to better growth performance and cost-effectiveness in poultry production.

Effects on Poultry Growth and Health

Floor feeding promotes natural foraging behavior and reduces competition among poultry, leading to improved feed intake and uniform growth rates. Pan feeding allows precise feed distribution and minimizes wastage, enhancing nutrient absorption and lowering the risk of feed contamination. Both methods impact poultry health differently, with floor feeding reducing stress and pan feeding limiting exposure to pathogens through cleaner feeding environments.

Labor and Maintenance Requirements

Floor feeding in poultry farming demands higher labor input for regular cleaning to prevent feed wastage and contamination, while pan feeding streamlines feed distribution with less frequent maintenance. Pan feeders reduce labor by allowing uniform feed access and minimizing spillage, leading to improved feed efficiency and hygiene. Labor costs decrease significantly with pan feeding systems due to automated refill options and easier sanitation compared to floor feeding methods.

Feed Wastage and Cost Implications

Floor feeding in poultry farming often results in higher feed wastage due to spillage and contamination, increasing overall feed costs. Pan feeding minimizes waste by containing feed within a controlled area, enhancing feed efficiency and reducing expenses. Choosing pan feeders can result in significant cost savings by optimizing feed utilization and lowering waste-related losses.

Biosecurity Considerations in Feed Distribution

Floor feeding in poultry farming increases the risk of contamination as feed is more exposed to pathogens, dirt, and droppings, compromising biosecurity. Pan feeding system confines feed to designated trays, significantly reducing feed waste and the likelihood of disease transmission by preventing contact with contaminated surfaces. Implementing pan feeding enhances overall flock health by maintaining cleaner feed environments and minimizing exposure to infectious agents.

Suitability for Different Poultry Farm Sizes

Floor feeding suits small-scale poultry farms by enabling easy distribution of feed over a large surface, reducing equipment costs and requiring minimal infrastructure. Pan feeding is ideal for medium to large poultry farms, offering uniform feed allocation and minimizing wastage through controlled portions in feed pans. Farm size, labor availability, and feed management objectives determine the optimal feeding method for efficient poultry nutrition delivery.

Choosing the Right Feeding System for Your Flock

Choosing the right feeding system for your flock depends on factors like flock size, feed wastage, and hygiene management. Floor feeding offers simplicity and accommodates large flocks but increases feed wastage and contamination risks, while pan feeding ensures controlled portions and reduces waste, promoting better health. Evaluating your poultry operation's needs and budget helps determine whether floor or pan feeding enhances feed efficiency and bird welfare.

Related Important Terms

Precision Feeding Zones

Precision feeding zones in poultry farming enhance feed distribution accuracy by using pan feeding systems, which localize feed delivery and minimize waste compared to floor feeding. Pan feeders ensure uniform feed access and sanitation, optimizing bird nutrition and growth performance through controlled portioning within designated feeding areas.

Feed Conversion Micro-management

Floor feeding in poultry farming often leads to uneven feed distribution and increased wastage, negatively impacting feed conversion ratios (FCR). Pan feeding promotes uniform access to feed, supporting precise micro-management of feed intake and enhancing overall feed conversion efficiency.

Automated Pan Feeders

Automated pan feeders enhance feed distribution precision and reduce waste compared to traditional floor feeding by delivering consistent portions directly to poultry, optimizing nutrient intake and minimizing contamination risks. This technology improves flock uniformity and feed efficiency, contributing to better growth rates and lower labor costs in poultry farming operations.

Floor Scatter Distribution

Floor scatter distribution in poultry farming allows feed to be spread broadly across the pen, promoting natural foraging behavior and reducing feed competition among birds. This method increases feed accessibility and can enhance overall flock uniformity compared to pan feeding, which restricts distribution to confined areas.

Sensor-Driven Feeders

Sensor-driven feeders in poultry farming optimize feed distribution by precisely controlling feed delivery, reducing waste compared to traditional floor feeding methods. Pan feeding enhances feed accessibility and hygiene, while sensors further improve efficiency by monitoring consumption patterns and adjusting feed amounts accordingly.

Biosecurity Feed Placement

Pan feeding systems enhance biosecurity by reducing feed contamination and minimizing waste compared to floor feeding, which exposes feed to pathogens and pests. Proper feed placement via pan feeders limits disease transmission risks and promotes healthier poultry environments.

Selective Pecking Behavior

Selective pecking behavior causes uneven feed intake in floor feeding systems, leading to increased feed wastage and reduced growth uniformity among poultry. Pan feeding minimizes selective pecking by providing uniform access to feed, promoting consistent nutrient consumption and improved feed efficiency.

Feed Access Uniformity

Floor feeding in poultry farming often results in uneven feed access, leading to competition and variable nutrient intake among birds, whereas pan feeding ensures more uniform distribution and consistent availability of feed, promoting equitable access and reducing feed wastage. Uniform feed access through pan feeding improves growth rates and flock performance by minimizing dominance hierarchies and feed deprivation.

Smart Feeding Analytics

Smart feeding analytics in poultry farming enhances feed distribution by optimizing floor feeding and pan feeding methods, improving feed conversion ratios and reducing waste. Advanced sensors and data-driven algorithms monitor consumption patterns, enabling precise adjustments to feeding schedules and quantities for each system.

Litter-Floor Feed Interaction

Floor feeding in poultry farming allows feed to mix directly with litter, increasing the risk of feed contamination and nutrient loss through spillage and moisture absorption. Pan feeding minimizes litter-floor feed interaction by containing feed in elevated trays, promoting cleaner feed consumption and reducing wastage.

Floor Feeding vs Pan Feeding for Feed Distribution Infographic

agridif.com

agridif.com