Wet litter in poultry farming leads to increased ammonia levels, promoting disease and discomfort among birds, whereas dry litter provides a healthier environment by reducing microbial growth. Proper bedding maintenance with dry litter improves bird welfare and enhances overall farm hygiene by absorbing moisture efficiently. Regular monitoring and timely replacement of bedding materials ensure optimal litter conditions and contribute to sustainable poultry production.

Table of Comparison

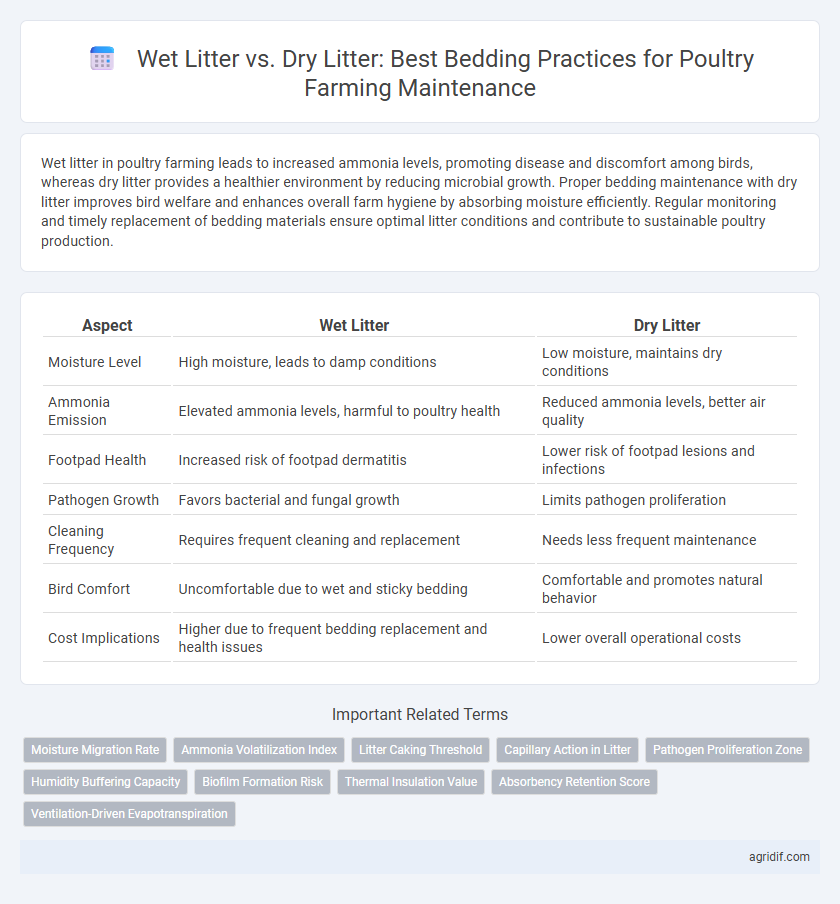

| Aspect | Wet Litter | Dry Litter |

|---|---|---|

| Moisture Level | High moisture, leads to damp conditions | Low moisture, maintains dry conditions |

| Ammonia Emission | Elevated ammonia levels, harmful to poultry health | Reduced ammonia levels, better air quality |

| Footpad Health | Increased risk of footpad dermatitis | Lower risk of footpad lesions and infections |

| Pathogen Growth | Favors bacterial and fungal growth | Limits pathogen proliferation |

| Cleaning Frequency | Requires frequent cleaning and replacement | Needs less frequent maintenance |

| Bird Comfort | Uncomfortable due to wet and sticky bedding | Comfortable and promotes natural behavior |

| Cost Implications | Higher due to frequent bedding replacement and health issues | Lower overall operational costs |

Understanding Poultry Litter: Wet vs Dry

Effective poultry litter management hinges on maintaining dry bedding to prevent wet litter conditions that promote bacterial growth and ammonia buildup, adversely affecting bird health and productivity. Wet litter increases the risk of footpad dermatitis, respiratory issues, and the proliferation of pathogens such as Escherichia coli and Salmonella, leading to economic losses in poultry operations. Optimal litter materials like pine shavings or rice hulls with proper ventilation and moisture control ensure dry bedding, enhancing bird welfare and maintaining biosecurity standards.

Factors Influencing Litter Moisture Levels

Litter moisture levels in poultry farming are influenced by factors such as bird density, ventilation rate, and water management practices. High humidity, inadequate airflow, and water spillage contribute to wet litter, increasing the risk of ammonia buildup and bacterial growth. Proper control of these variables supports optimal dry litter conditions, enhancing poultry health and performance.

Health Impacts: Wet Litter vs Dry Litter

Wet litter in poultry farming significantly increases the risk of footpad dermatitis, respiratory infections, and bacterial proliferation, compromising bird welfare and productivity. Dry litter creates a healthier environment by reducing ammonia levels, minimizing pathogen growth, and promoting better air quality. Maintaining dry litter through proper ventilation, moisture control, and frequent bedding replacement is essential for optimal poultry health and farm biosecurity.

Litter Type and Performance in Broiler Houses

Dry litter materials like wood shavings and rice hulls promote better moisture absorption and reduce ammonia levels, enhancing broiler performance and welfare. Wet litter, often caused by high humidity or poor ventilation, leads to increased pathogen growth, footpad dermatitis, and lower feed efficiency. Choosing highly absorbent, low-dust bedding combined with proper litter management optimizes growth rates and reduces health risks in broiler houses.

Managing Ammonia: The Role of Litter Moisture

Managing ammonia levels in poultry houses is directly influenced by litter moisture, with wet litter promoting higher ammonia emission due to increased microbial activity breaking down uric acid. Dry litter absorbs moisture more effectively, reducing ammonia volatilization and improving air quality, which is essential for bird health and productivity. Optimal bedding maintenance involves maintaining litter moisture below 25%, using absorbent materials like wood shavings, and ensuring proper ventilation to mitigate ammonia accumulation.

Wet Litter: Causes and Consequences

Wet litter in poultry farming primarily results from excessive moisture due to high humidity, inadequate ventilation, water spillage, or poor drainage in the bedding area. Persistent wet litter fosters bacterial growth, increases ammonia levels, and leads to footpad dermatitis, respiratory issues, and compromised bird health. Maintaining dry litter is crucial to prevent disease outbreaks, optimize bird welfare, and enhance overall flock productivity.

Advantages of Dry Litter for Poultry Bedding

Dry litter in poultry bedding enhances bird health by reducing ammonia levels and minimizing microbial growth, leading to lower respiratory issues and improved overall hygiene. It promotes better moisture control, which decreases the risk of footpad dermatitis and other infections, thus optimizing bird welfare. Maintaining dry litter also supports structural integrity, ensuring comfort and encouraging natural behaviors essential for poultry productivity.

Practices for Maintaining Optimal Litter Dryness

Maintaining optimal litter dryness in poultry farming relies on precise moisture control through regular ventilation, prompt removal of wet spots, and consistent litter turning to enhance aeration. Using absorbent materials like wood shavings or rice hulls improves moisture absorption and prevents ammonia buildup, which is crucial for bird health. Monitoring environmental factors such as humidity and drinker system leaks ensures wet litter conditions are minimized, promoting better hygiene and reducing the risk of pathogens.

Cost Implications: Wet Litter vs Dry Litter Management

Wet litter in poultry farming increases costs due to higher ammonia levels, leading to respiratory issues and reduced bird growth rates, thereby escalating veterinary expenses and productivity losses. Dry litter management minimizes moisture retention, reducing the need for frequent bedding replacement and lowering labor and material costs. Investing in effective ventilation and moisture control systems for dry litter maintenance proves economically beneficial by enhancing bird welfare and extending bedding lifespan.

Selecting the Best Bedding Material for Litter Control

Selecting the best bedding material for poultry litter control hinges on moisture absorption capacity and durability, with dry litter materials like wood shavings and rice hulls preferred for their excellent moisture-wicking properties. Wet litter leads to increased ammonia levels and risk of footpad dermatitis, making highly absorbent bedding essential to maintain bird health and optimize growth performance. Proper ventilation and frequent litter turning complement the choice of dry bedding, ensuring a balanced microenvironment that supports litter dryness and reduces pathogen proliferation.

Related Important Terms

Moisture Migration Rate

Wet litter in poultry farming significantly increases the moisture migration rate, leading to higher ammonia levels and the proliferation of pathogens that compromise bird health and growth. Maintaining dry litter with low moisture migration improves air quality, reduces disease risk, and enhances overall production efficiency by providing a healthier environment for the flock.

Ammonia Volatilization Index

Wet litter in poultry farming significantly increases the Ammonia Volatilization Index (AVI), leading to higher ammonia emissions that can harm bird respiratory health and reduce growth performance. Maintaining dry litter through proper ventilation and moisture control effectively lowers AVI, improving air quality and overall poultry welfare.

Litter Caking Threshold

Wet litter increases the risk of litter caking, which occurs when moisture levels surpass 25-30%, leading to hardened bedding that fosters bacterial growth and ammonia buildup. Maintaining dry litter below this threshold ensures optimal poultry health, reduces footpad dermatitis, and improves overall barn air quality.

Capillary Action in Litter

Effective poultry bedding maintenance hinges on managing capillary action within litter; wet litter promotes moisture wicking through capillary forces, raising ammonia levels and increasing the risk of footpad dermatitis. Dry litter, achieved by controlling moisture absorption and evaporation rates, minimizes capillary moisture movement, thereby enhancing bird comfort and reducing pathogenic microbial growth.

Pathogen Proliferation Zone

Wet litter in poultry farming creates a pathogen proliferation zone by providing ideal moisture levels for bacteria such as Salmonella and E. coli to thrive, increasing disease risk among flocks. Maintaining dry litter reduces microbial growth, enhancing bird health and minimizing contamination in bedding environments.

Humidity Buffering Capacity

Dry litter in poultry farming enhances humidity buffering capacity by absorbing moisture and maintaining stable environmental conditions, which reduces ammonia levels and promotes bird health. Wet litter, conversely, diminishes this buffering effect, leading to increased humidity, higher pathogen proliferation, and compromised poultry welfare.

Biofilm Formation Risk

Wet litter in poultry farming significantly increases the risk of biofilm formation by providing a moist environment conducive to bacterial growth, which can lead to persistent contamination and disease outbreaks. Maintaining dry litter through proper ventilation and moisture control reduces biofilm development, enhancing flock health and improving overall bedding sanitation.

Thermal Insulation Value

Dry litter in poultry housing offers superior thermal insulation value compared to wet litter, helping to maintain stable floor temperatures and reducing energy costs for heating. Wet litter not only compromises insulation by increasing thermal conductivity but also elevates moisture levels, which can lead to heat loss and negatively impact bird comfort and growth performance.

Absorbency Retention Score

Wet litter significantly decreases absorbency retention scores compared to dry litter, leading to higher moisture levels that promote bacterial growth and ammonia production in poultry houses. Maintaining dry litter with a high absorbency retention score enhances bird comfort, reduces health risks, and improves overall flock performance.

Ventilation-Driven Evapotranspiration

Effective ventilation enhances evapotranspiration, maintaining dry litter by removing moisture from poultry bedding and reducing ammonia buildup, which benefits bird health and productivity. In contrast, inadequate airflow leads to wet litter, increasing the risk of pathogens and respiratory issues, thereby compromising overall flock welfare.

Wet Litter vs Dry Litter for Bedding Maintenance Infographic

agridif.com

agridif.com