Open-sided sheds provide natural ventilation that helps maintain airflow and reduce humidity, making them suitable for mild climates where temperature fluctuations are minimal. Environment-controlled sheds offer precise regulation of temperature, humidity, and ventilation, which is crucial for poultry farming in extreme or unpredictable climates to ensure optimal bird health and productivity. Choosing between these shed types depends on local weather conditions and the specific needs of the poultry to maximize comfort and growth.

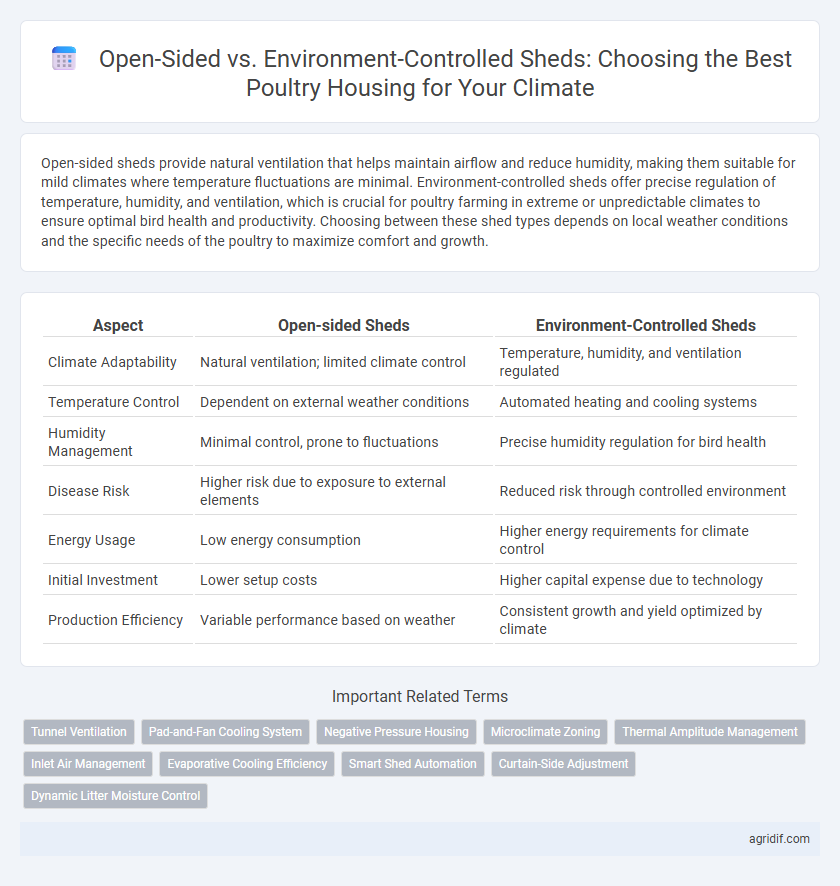

Table of Comparison

| Aspect | Open-sided Sheds | Environment-Controlled Sheds |

|---|---|---|

| Climate Adaptability | Natural ventilation; limited climate control | Temperature, humidity, and ventilation regulated |

| Temperature Control | Dependent on external weather conditions | Automated heating and cooling systems |

| Humidity Management | Minimal control, prone to fluctuations | Precise humidity regulation for bird health |

| Disease Risk | Higher risk due to exposure to external elements | Reduced risk through controlled environment |

| Energy Usage | Low energy consumption | Higher energy requirements for climate control |

| Initial Investment | Lower setup costs | Higher capital expense due to technology |

| Production Efficiency | Variable performance based on weather | Consistent growth and yield optimized by climate |

Introduction to Poultry Housing: Open-Sided vs Environment-Controlled Sheds

Open-sided poultry sheds provide natural ventilation and cost-effective housing suited for moderate climates, promoting bird health through fresh air circulation. Environment-controlled sheds maintain optimal temperature, humidity, and air quality using automated systems, ideal for extreme weather conditions and high-density production. Selecting the appropriate housing type depends on regional climate, flock size, and management goals to ensure optimal poultry growth and welfare.

Understanding Climate Impact on Poultry Farming

Open-sided sheds provide natural ventilation but expose poultry to fluctuating temperatures and humidity, increasing stress and reducing productivity in extreme climates. Environment-controlled sheds maintain stable temperature, humidity, and airflow through advanced systems, optimizing bird health and growth rates regardless of external weather conditions. Understanding regional climate patterns is crucial for choosing the appropriate shed type to enhance poultry welfare and maximize farm efficiency.

Design Features of Open-Sided Poultry Sheds

Open-sided poultry sheds feature large, unobstructed vents along the walls to maximize natural airflow, crucial for temperature regulation in hot climates. Their design includes elevated floors and wide eaves to enhance ventilation and reduce heat stress for birds. These sheds typically utilize lightweight materials like galvanized steel and polyethylene curtains to facilitate rapid air exchange and maintain poultry health.

Key Characteristics of Environment-Controlled Poultry Sheds

Environment-controlled poultry sheds maintain optimal temperature, humidity, and ventilation using automated systems like fans, heaters, and cooling pads to ensure consistent climate conditions. These sheds enhance bird health and productivity by minimizing stress from external weather fluctuations. High insulation levels and precise air quality management distinguish environment-controlled sheds from open-sided alternatives, promoting better growth rates and feed efficiency.

Temperature Regulation: Open-Sided vs Environment-Controlled Sheds

Open-sided poultry sheds rely on natural ventilation for temperature regulation, making them suitable in moderate climates but less effective in extreme heat or cold. Environment-controlled sheds use advanced HVAC systems to maintain consistent temperature and humidity levels, optimizing bird comfort and growth rates year-round. Precision in temperature control reduces stress and disease risk, directly enhancing productivity and feed efficiency.

Ventilation and Air Quality Considerations

Open-sided poultry sheds promote natural ventilation, which helps reduce humidity and ammonia levels but may struggle to maintain consistent temperature control in extreme weather conditions. Environment-controlled sheds utilize mechanical ventilation systems to regulate airflow, temperature, and humidity, ensuring optimal air quality and minimizing respiratory diseases in poultry. Effective air exchange rates and filtration systems in environment-controlled sheds significantly improve bird health and productivity compared to open-sided designs.

Energy Efficiency and Cost Comparison

Open-sided poultry sheds offer natural ventilation, reducing energy use but exposing birds to temperature fluctuations, which can affect productivity. Environment-controlled sheds optimize climate with heating, cooling, and humidity systems, enhancing bird health and growth but incurring higher energy costs. Choosing between them depends on balancing initial investment, ongoing energy expenses, and climate conditions to maximize operational efficiency.

Bird Health and Welfare in Different Shed Types

Open-sided poultry sheds provide natural ventilation that reduces heat stress and promotes air quality, supporting bird health in moderate climates. Environment-controlled sheds offer precise regulation of temperature, humidity, and lighting, minimizing disease risk and enhancing welfare during extreme weather conditions. Choosing the shed type depends on local climate factors and the ability to maintain optimal environmental conditions critical for poultry immunity and productivity.

Suitability of Shed Types for Various Climates

Open-sided sheds offer natural ventilation and are ideal for hot, humid climates where air circulation reduces heat stress on poultry. Environment-controlled sheds provide precise temperature, humidity, and airflow management, making them suitable for cold or variable climates where maintaining stable conditions is crucial for bird health and productivity. Choosing the right shed type depends on climate factors, regional weather patterns, and specific poultry species requirements to optimize growth performance and welfare.

Choosing the Ideal Poultry Shed for Optimal Productivity

Open-sided poultry sheds enhance ventilation and reduce heat stress in tropical climates, promoting healthier bird growth and higher egg production. Environment-controlled sheds provide precise temperature and humidity regulation, essential for maintaining optimal conditions in colder or highly variable climates, thus maximizing feed conversion efficiency. Selecting the ideal poultry shed depends on regional climate, with open-sided structures favored in hot, humid areas and environment-controlled facilities preferred for consistent climate control to boost overall productivity.

Related Important Terms

Tunnel Ventilation

Tunnel ventilation in environment-controlled poultry sheds provides consistent airflow and precise temperature regulation, enhancing bird health and productivity compared to open-sided sheds. Open-sided structures rely on natural air movement, which can lead to uneven climate conditions and increased stress for poultry.

Pad-and-Fan Cooling System

The pad-and-fan cooling system in environment-controlled poultry sheds maintains optimal temperature and humidity by forcing air through wet pads, crucial for heat stress management in hot climates. Open-sided sheds lack this efficient cooling mechanism, making environment-controlled systems superior for maximizing bird comfort and productivity.

Negative Pressure Housing

Negative pressure housing in poultry farming uses mechanical ventilation to maintain optimal airflow and climate control, reducing humidity and ammonia levels more effectively than open-sided sheds. This environment-controlled approach enhances bird health and productivity by providing consistent temperature regulation and improved air quality, especially in extreme weather conditions.

Microclimate Zoning

Open-sided sheds in poultry farming promote natural ventilation but limit precise microclimate zoning, often leading to uneven temperature and humidity levels that affect bird health and productivity. Environment-controlled sheds utilize advanced systems to create distinct microclimate zones, optimizing temperature, humidity, and airflow for improved poultry welfare and consistent performance throughout varying weather conditions.

Thermal Amplitude Management

Open-sided poultry sheds provide natural ventilation but struggle to regulate thermal amplitude, exposing birds to temperature fluctuations that can stress immune function and reduce productivity. Environment-controlled sheds maintain stable temperatures using insulated walls, automated heating, and cooling systems, effectively minimizing thermal amplitude and promoting optimal bird health and growth.

Inlet Air Management

Open-sided poultry sheds rely on natural ventilation for inlet air management, which can result in inconsistent airflow and temperature fluctuations affecting bird comfort and productivity. Environment-controlled sheds use adjustable inlet air systems with fans and sensors, precisely regulating airflow and maintaining optimal temperature and humidity for enhanced poultry health and performance.

Evaporative Cooling Efficiency

Open-sided poultry sheds utilize natural ventilation enhanced by evaporative cooling pads that reduce temperatures efficiently in dry, hot climates, improving bird comfort and growth rates. In contrast, environment-controlled sheds integrate advanced evaporative cooling systems with fans and sensors, maintaining consistent humidity and temperature levels, which optimizes energy use and maximizes poultry welfare in diverse climatic conditions.

Smart Shed Automation

Open-sided poultry sheds maximize natural ventilation but are vulnerable to temperature fluctuations, while environment-controlled sheds maintain optimal climate through automated systems like temperature sensors, fans, and misting devices. Smart shed automation enhances environment-controlled sheds by integrating IoT-driven monitoring and adaptive controls, ensuring consistent poultry welfare and improved productivity regardless of external weather conditions.

Curtain-Side Adjustment

Curtain-side adjustment in open-sided poultry sheds allows for natural ventilation and temperature regulation by manually varying the curtain height, optimizing airflow in moderate climates. Environment-controlled sheds utilize automated curtain systems integrated with sensors to maintain precise temperature and humidity levels, enhancing bird comfort and productivity in extreme weather conditions.

Dynamic Litter Moisture Control

Dynamic litter moisture control in environment-controlled sheds offers precise regulation of temperature and humidity, significantly reducing moisture accumulation and promoting healthier poultry environments. Open-sided sheds rely on natural ventilation which may lead to inconsistent litter moisture levels, increasing the risk of pathogens and affecting bird welfare.

Open-sided vs Environment-Controlled Sheds for Climate Infographic

agridif.com

agridif.com