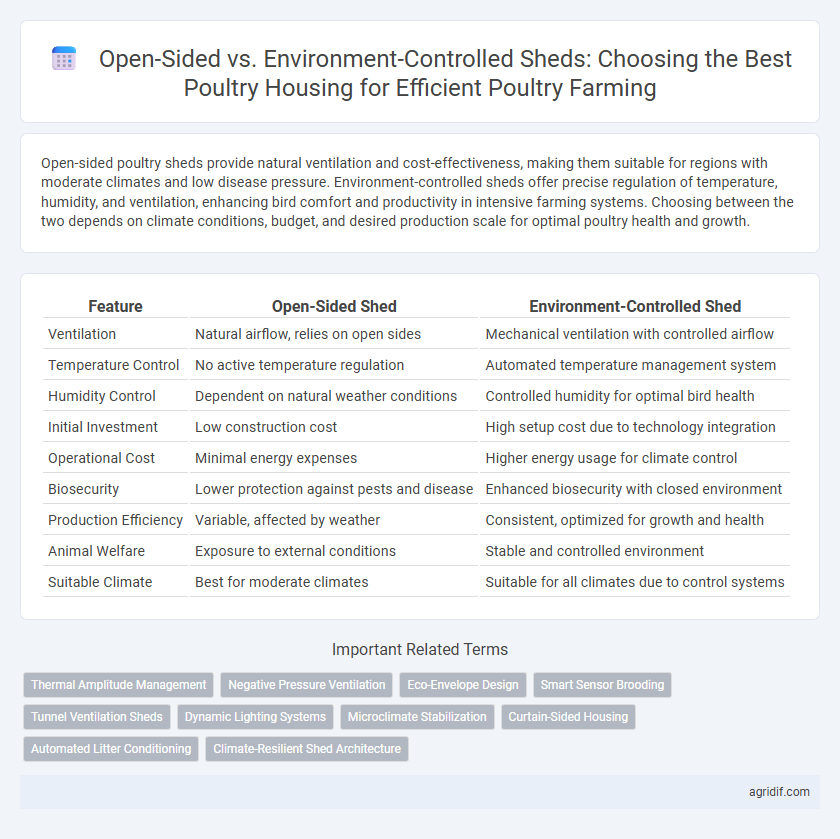

Open-sided poultry sheds provide natural ventilation and cost-effectiveness, making them suitable for regions with moderate climates and low disease pressure. Environment-controlled sheds offer precise regulation of temperature, humidity, and ventilation, enhancing bird comfort and productivity in intensive farming systems. Choosing between the two depends on climate conditions, budget, and desired production scale for optimal poultry health and growth.

Table of Comparison

| Feature | Open-Sided Shed | Environment-Controlled Shed |

|---|---|---|

| Ventilation | Natural airflow, relies on open sides | Mechanical ventilation with controlled airflow |

| Temperature Control | No active temperature regulation | Automated temperature management system |

| Humidity Control | Dependent on natural weather conditions | Controlled humidity for optimal bird health |

| Initial Investment | Low construction cost | High setup cost due to technology integration |

| Operational Cost | Minimal energy expenses | Higher energy usage for climate control |

| Biosecurity | Lower protection against pests and disease | Enhanced biosecurity with closed environment |

| Production Efficiency | Variable, affected by weather | Consistent, optimized for growth and health |

| Animal Welfare | Exposure to external conditions | Stable and controlled environment |

| Suitable Climate | Best for moderate climates | Suitable for all climates due to control systems |

Introduction to Poultry Housing Systems

Open-sided poultry sheds provide natural ventilation and lower initial costs, making them suitable for regions with mild climates and lower biosecurity risks. Environment-controlled sheds offer precise regulation of temperature, humidity, and ventilation, optimizing bird comfort, feed conversion, and production efficiency, especially in areas with extreme weather conditions. Selection between these systems depends on climate, disease control measures, and production goals to ensure poultry health and maximize profitability.

Key Differences Between Open-Sided and Environment-Controlled Sheds

Open-sided poultry sheds rely on natural ventilation, allowing air circulation but exposing birds to external weather variations, while environment-controlled sheds use mechanical systems to regulate temperature, humidity, and airflow for optimal poultry comfort. Open-sided designs typically have lower initial costs and energy consumption but risk higher disease exposure and inconsistent environmental conditions. In contrast, environment-controlled sheds provide precise climate control, higher biosecurity, and improved growth performance, though they require significant investment and higher operational expenses.

Climate and Environmental Considerations

Open-sided poultry sheds provide natural ventilation that suits tropical and subtropical climates by reducing heat stress and improving air quality for birds. Environment-controlled sheds offer precise management of temperature, humidity, and ventilation, essential in regions with extreme weather fluctuations or intensive poultry production systems. Choosing between these housing types depends on local climate conditions, energy availability, and the desired level of biosecurity for optimal poultry health and productivity.

Construction Costs and Investment Analysis

Open-sided poultry sheds generally require lower initial construction costs due to simpler design and minimal insulation, making them suitable for small-scale farms in moderate climates. Environment-controlled sheds involve higher investment because of advanced ventilation, heating, and cooling systems that ensure optimal conditions for bird health and productivity year-round. A thorough investment analysis must consider long-term operational savings through improved growth rates and reduced mortality in environment-controlled systems against the upfront capital expense.

Energy Consumption and Efficiency

Open-sided poultry sheds naturally ventilate, reducing energy consumption but are less efficient in temperature control, leading to potential heat stress in birds. Environment-controlled sheds use advanced HVAC systems to maintain optimal climate conditions, increasing energy use but significantly enhancing productivity and bird health. Balancing energy efficiency with environmental control is crucial for sustainable poultry farming, as precise climate management boosts feed conversion ratios and reduces mortality rates.

Impact on Bird Health and Welfare

Open-sided poultry sheds provide natural ventilation, reducing humidity and ammonia levels, which helps minimize respiratory diseases and promotes bird comfort. Environment-controlled sheds maintain consistent temperature, humidity, and air quality, enhancing health by preventing heat stress and cold-related illnesses. Proper management in both systems is essential to optimize bird welfare and productivity.

Productivity and Performance Outcomes

Open-sided poultry sheds provide natural ventilation that reduces heat stress and lowers energy costs, promoting bird comfort and steady growth rates in moderate climates. Environment-controlled sheds optimize temperature, humidity, and air quality, leading to improved feed conversion ratios, higher egg production, and reduced mortality rates, especially in regions with extreme weather conditions. Choice of poultry housing significantly impacts productivity metrics and overall flock performance, with environment-controlled systems offering superior yield consistency and disease management.

Biosecurity and Disease Management

Open-sided poultry sheds provide natural ventilation, reducing ammonia buildup but exposing flocks to external contaminants and pests, which can compromise biosecurity. Environment-controlled sheds maintain strict temperature, humidity, and air quality, significantly minimizing disease transmission by limiting pathogen entry and improving sanitation protocols. Investing in environment-controlled housing enhances precise disease management and biosecurity measures, ultimately reducing mortality rates and promoting healthier poultry production.

Sustainability and Environmental Footprint

Open-sided poultry sheds promote natural ventilation and reduce energy consumption, contributing to lower carbon footprints in sustainable poultry farming. Environment-controlled sheds enable precise regulation of temperature and humidity, enhancing bird welfare and productivity but often require significant energy input, impacting sustainability. Balancing these housing options involves assessing local climate conditions and energy sources to optimize environmental footprint while maintaining healthy poultry growth.

Choosing the Right Housing System for Your Poultry Farm

Choosing the right poultry housing system depends on climate conditions, flock size, and management goals. Open-sided sheds offer natural ventilation and lower construction costs, ideal for moderate climates but may expose birds to temperature fluctuations and predators. Environment-controlled sheds provide precise regulation of temperature, humidity, and ventilation, enhancing bird comfort and productivity, especially in extreme weather or high-density operations.

Related Important Terms

Thermal Amplitude Management

Open-sided poultry sheds rely on natural ventilation to moderate temperature fluctuations, often leading to wider thermal amplitude that impacts bird comfort and productivity. Environment-controlled sheds use automated systems to maintain consistent temperature and humidity levels, effectively minimizing thermal amplitude and enhancing poultry health and growth efficiency.

Negative Pressure Ventilation

Open-sided poultry sheds offer natural ventilation but lack precise climate control, leading to inconsistent air quality and temperature fluctuations that can negatively impact bird health. Environment-controlled sheds with negative pressure ventilation maintain optimal airflow and temperature by mechanically removing stale air, reducing ammonia levels and enhancing overall bird performance.

Eco-Envelope Design

Open-sided poultry sheds leverage natural ventilation and ambient conditions, reducing energy consumption while maintaining bird health, which aligns with sustainable farming practices. Environment-controlled sheds using eco-envelope designs incorporate insulated walls, automated ventilation, and temperature regulation systems to optimize microclimate conditions, enhancing productivity and biosecurity in intensive poultry operations.

Smart Sensor Brooding

Smart sensor brooding in environment-controlled poultry sheds enables precise regulation of temperature, humidity, and ventilation, optimizing chick comfort and growth rates. Unlike open-sided housing, which relies on natural airflow and is vulnerable to weather fluctuations, environment-controlled systems enhance productivity and disease prevention through automated monitoring and adjustments.

Tunnel Ventilation Sheds

Tunnel ventilation sheds in poultry farming utilize high-speed fans to create a controlled airflow environment, significantly improving air quality and temperature regulation compared to open-sided sheds. These environment-controlled sheds enhance bird health and growth performance by reducing heat stress and ammonia buildup, leading to higher productivity and biosecurity standards.

Dynamic Lighting Systems

Dynamic lighting systems in environment-controlled poultry sheds optimize bird growth and welfare by simulating natural daylight variations, enhancing circadian rhythms and reducing stress. In contrast, open-sided sheds rely on natural light fluctuations that may lead to inconsistent illumination, potentially affecting poultry productivity and health.

Microclimate Stabilization

Open-sided poultry sheds rely on natural ventilation to moderate temperature and humidity, which can lead to fluctuating microclimate conditions affecting bird comfort and growth performance. In contrast, environment-controlled sheds utilize advanced HVAC systems to maintain consistent temperature, humidity, and air quality, optimizing microclimate stabilization for improved poultry health and productivity.

Curtain-Sided Housing

Curtain-sided housing in poultry farming offers a cost-effective solution with natural ventilation, promoting airflow and reducing heat stress in birds compared to closed, environment-controlled sheds. This semi-open design balances environmental exposure and protection, optimizing bird health and productivity while minimizing energy consumption for ventilation.

Automated Litter Conditioning

Open-sided poultry sheds offer natural ventilation but lack precise control over humidity and temperature, making automated litter conditioning less effective in maintaining optimal dryness and reducing pathogen load. In contrast, environment-controlled sheds utilize automated litter conditioning systems integrated with climate controls to consistently manage moisture, enhance bird comfort, and improve overall flock health and productivity.

Climate-Resilient Shed Architecture

Open-sided poultry sheds offer natural ventilation and cost-efficiency but expose birds to variable weather conditions, impacting temperature regulation and disease control. Environment-controlled sheds utilize advanced HVAC systems and insulation to maintain optimal temperature, humidity, and air quality, enhancing poultry health and productivity in diverse climatic conditions.

Open-Sided vs Environment-Controlled Shed for Poultry Housing Infographic

agridif.com

agridif.com